Centralized leakage detection device and method for airtight cooling system of blast furnace

A cooling system and blast furnace technology, applied in the field of blast furnaces, can solve problems such as inability to confirm, and achieve the effects of increasing leak detection speed, reducing leak detection operation frequency, and reasonable and more scientific detection and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

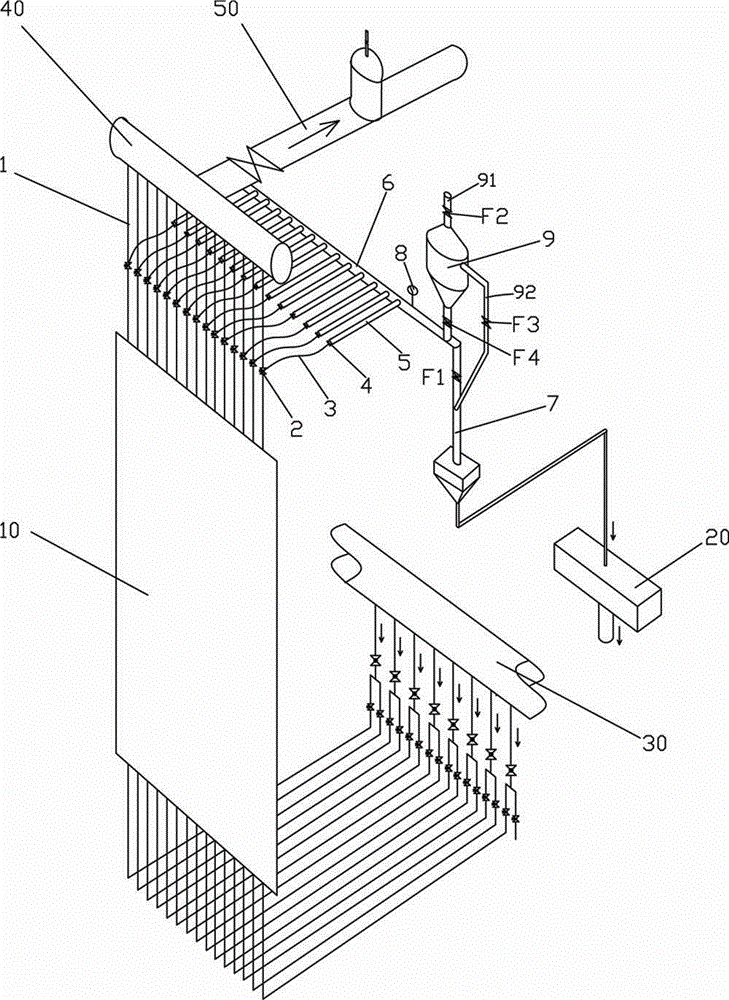

[0040] see figure 1 , the centralized leak detection device of the blast furnace airtight cooling system of the present invention, said blast furnace airtight cooling system is provided with several cooler branch pipe water strings 1 along the blast furnace circumference, said several cooler branch pipe water strings are equally divided into several sub-areas 10 along the blast furnace circumference , each sub-area 10 includes 10 to 15 cooler branch pipe water strings 1 and corresponding water supply ring pipes 30, return water ring pipes 40, return water headers and gas traps 50, and each sub-area 10 is a centralized inspection Leakage area; the cooler branch pipeline water string 1 in each sub-area 10 is respectively connected to a connecting hose 3 through a three-way valve 2, and the connecting hose 3 is connected to a connecting branch pipe 5 through a quick joint 4, and each connecting branch pipe 5 is connected to To a connecting main pipe 6, the outlet end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com