Hyperconcentration clear water type laundry sheet and preparation method thereof

A laundry tablet and super-concentration technology, applied in the field of daily washing products, can solve the problems of difficult dissolution, slow dissolution rate, turbid water, etc., and achieve the effects of simple preparation steps, reduction of production costs, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

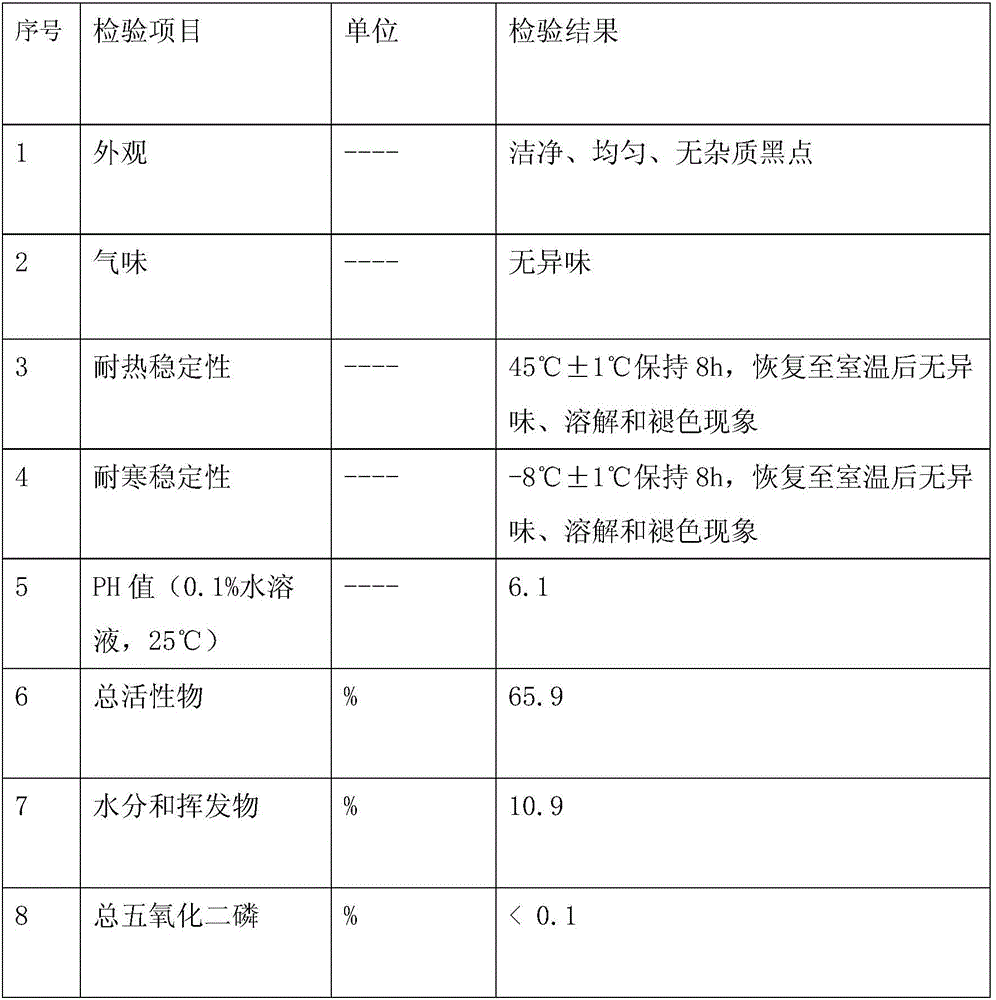

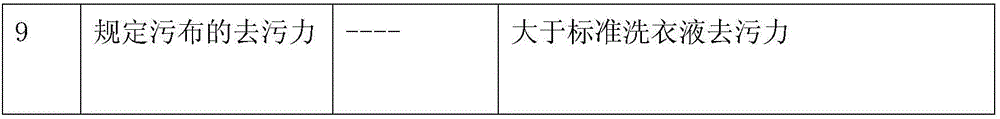

Image

Examples

Embodiment 1

[0053] A kind of ultra-concentrated clear water laundry tablet, described super-concentrated clear water laundry tablet is prepared from the raw material of following mass ratio:

[0054] Sodium Lauryl Sulfate 30%;

[0055] Sodium a-olefin sulfonate 10%;

[0056] Polyvinyl alcohol 11%;

[0057] Glycerin 3%;

[0058] Silicone oil 0.4%;

[0059] Pigment 0.4%;

[0060] Fragrance 0.6%;

[0061] Disodium EDTA 0.12%;

[0062] Sodium Citrate 1.25%;

[0063] Water 43.23%.

[0064] The preparation method of the ultra-concentrated clean water laundry tablet comprising the above raw materials comprises the following steps:

[0065] Step S1: Put the polyvinyl alcohol and the pigment into the emulsification pot in proportion, add 15% water, mix and stir evenly;

[0066] Step S2: Add sodium lauryl sulfate, sodium α-olefin sulfonate, glycerin, silicone oil, essence and disodium EDTA in proportion to the emulsification pot, and add the remaining water, mix and stir evenly;

[0067] ...

Embodiment 2

[0075] A kind of ultra-concentrated clear water laundry tablet, described super-concentrated clear water laundry tablet is prepared from the raw material of following mass ratio:

[0076] Sodium Lauryl Sulfate 33%;

[0077] Sodium a-olefin sulfonate 8%;

[0078] Polyvinyl alcohol 10.2%;

[0079] Glycerin 3.2%;

[0080] Silicone oil 0.5%;

[0081] Pigment 0.3%;

[0082] Fragrance 0.6%;

[0083] Disodium EDTA 0.11%;

[0084] Sodium Citrate 1.2%;

[0085] Water 42.89%.

[0086] The preparation method of the ultra-concentrated clean water laundry tablet comprising the above raw materials comprises the following steps:

[0087] Step S1: Put the polyvinyl alcohol and the pigment into the emulsification pot in proportion, add 13% water, mix and stir evenly;

[0088] Step S2: Add sodium lauryl sulfate, sodium α-olefin sulfonate, glycerin, silicone oil, essence and disodium EDTA in proportion to the emulsification pot, and add the remaining water, mix and stir evenly;

[0089...

Embodiment 3

[0094] A kind of ultra-concentrated clear water laundry tablet, described super-concentrated clear water laundry tablet is prepared from the raw material of following mass ratio:

[0095] Coconut Oil Fatty Acid Diethanolamide 40%;

[0096] Sucrose fatty acid ester 3%;

[0097] Polyvinyl alcohol 9%;

[0098] Glycerin 3%;

[0099] Silicone oil 0.4%;

[0100] Pigment 0.4%;

[0101] Fragrance 0.6%;

[0102] Disodium EDTA 0.18%;

[0103] Sodium Citrate 1.32%;

[0104] Water 42.1%.

[0105] The preparation method of the ultra-concentrated clean water laundry tablet comprising the above raw materials comprises the following steps:

[0106] Step S1: Put the polyvinyl alcohol and the pigment into the emulsification pot in proportion, add 12% water, mix and stir evenly;

[0107] Step S2: Add coconut oil fatty acid diethanolamide, sucrose fatty acid ester, glycerin, silicone oil, flavor and disodium EDTA in proportion to the emulsification pot, and add the remaining water, mix a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com