An environmentally friendly track and field track and its manufacturing method

A track, track and field technology, applied in the environmental track and field track and application field, to achieve the effect of reliable use, reducing maintenance trouble, and preventing bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

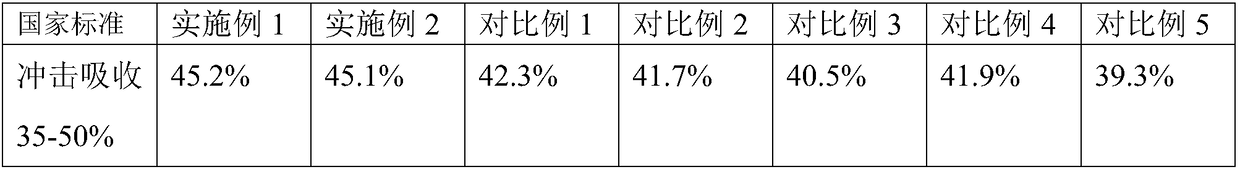

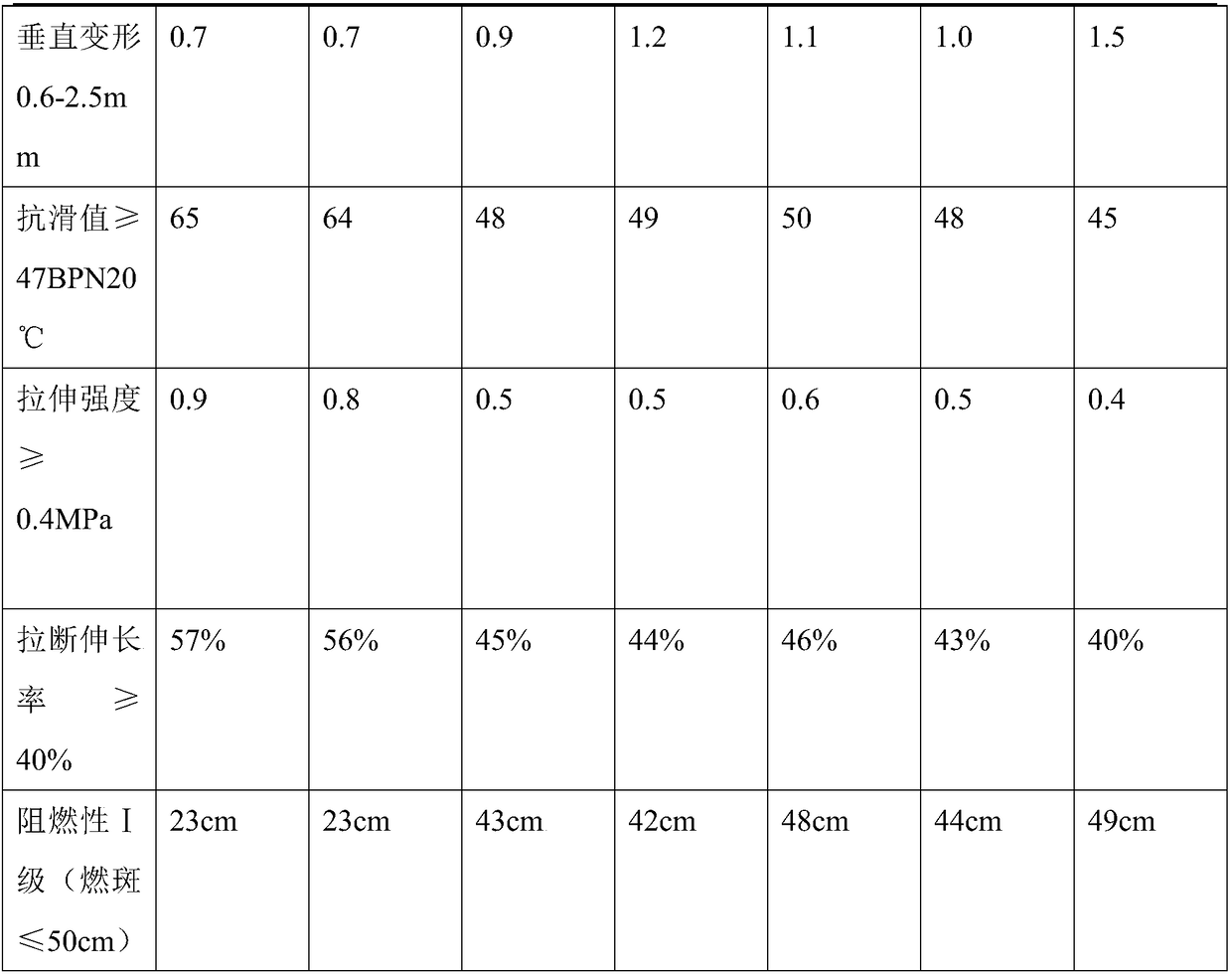

Examples

Embodiment 1

[0041] According to the environmentally friendly track and field formula, it contains 60% PVC paste resin, 37% dioctyl terephthalate, 2% calcium zinc stabilizer, 0.5% azodicarbonamide, 2-hydroxy-4-methoxybenzyl Ketone 0.2%, β-(3,5-di-tert-butyl-4-hydroxyphenyl)-n-octadecyl propionate 0.3%.

[0042] The production method is as follows,

[0043] (1) Ingredients: Add PVC paste resin, dioctyl terephthalate, calcium zinc stabilizer, azodicarbonamide, 2-hydroxy-4-methoxy group into the batching kettle equipped with mixing and cooling system. Benzene ketone, β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, stir and mix uniformly to obtain slurry;

[0044] (2) Exhaust: After the slurry is fully mixed, exhaust it at -0.4MPa for 30 minutes;

[0045] (3) Hanging slurry: evenly smear the exhausted slurry on the line, deposit an appropriate amount of slurry on the die head, and hang over the line with a suitable and uniform force and speed;

[0046] (4) Drying: Use a dryer to heat the...

Embodiment 2

[0050] According to the environmentally friendly track and field formula, it contains 60% PVC paste resin, 37% dioctyl terephthalate, 2% calcium zinc stabilizer, 0.5% azodicarbonamide, 2-hydroxy-4-methoxybenzyl Ketone 0.2%, β-(3,5-di-tert-butyl-4-hydroxyphenyl)-n-octadecyl propionate 0.3%.

[0051] The production method is as follows,

[0052] (1) Ingredients: Add PVC paste resin, dioctyl terephthalate, calcium zinc stabilizer, azodicarbonamide, 2-hydroxy-4-methoxy group into the batching kettle equipped with mixing and cooling system. Benzene ketone, β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, stir and mix uniformly to obtain slurry;

[0053] (2) Exhaust: After the slurry is fully mixed, exhaust it at -0.3MPa for half an hour;

[0054] (3) Hanging slurry: evenly smear the exhausted slurry on the line, deposit an appropriate amount of slurry on the die head, and hang over the line with a suitable and uniform force and speed;

[0055] (4) Drying: Use a dryer to heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com