Method and device for aerobic pressurization and high-temperature fermentation of solid organic substances

A solid organic matter, high temperature fermentation technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of difficult fermentation temperature and process, high cost of collection and transportation, difficult waste gas treatment, etc. The way of resource utilization and the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

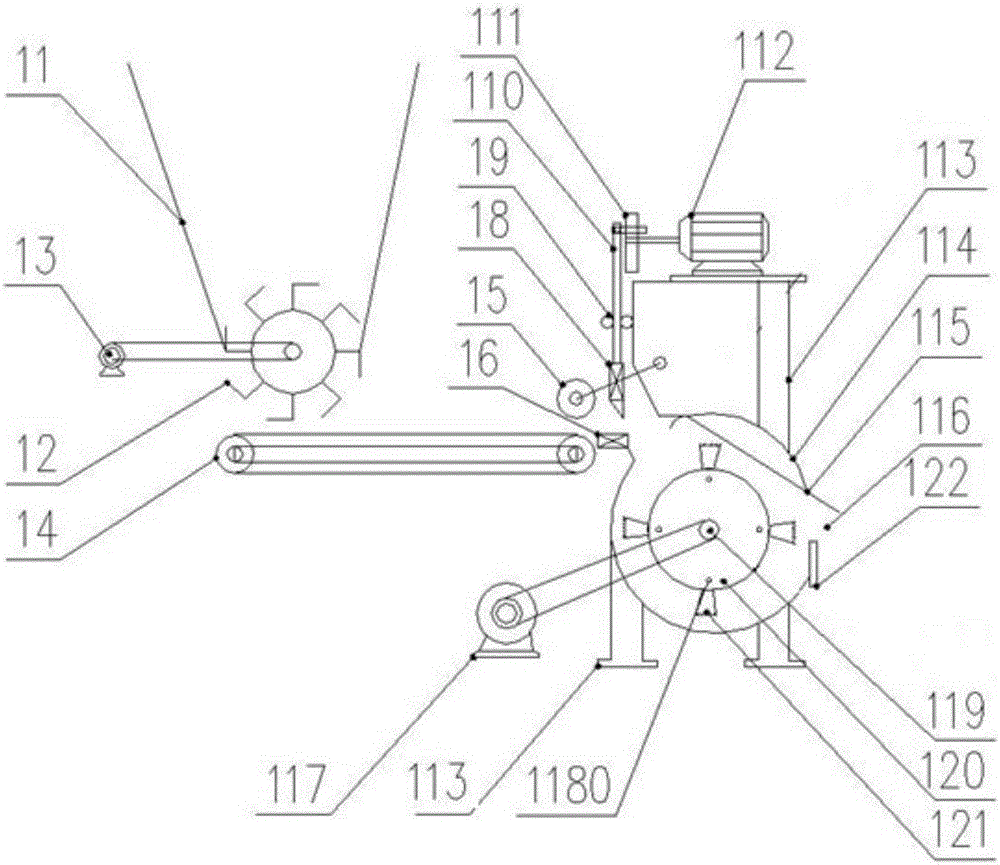

Image

Examples

Embodiment Construction

[0044] Below in conjunction with example, accompanying drawing, seat of the present invention is further described, and implementation of the present invention is not limited to following embodiment.

[0045] Such as figure 1 and figure 2 Shown, a method for aerobic pressurized high-temperature fermentation of solid organic matter, the process steps are:

[0046] The solid organic matter is classified by the grading equipment, and the long fibers enter the high-humidity solid organic matter pulverizer 1 for pulverization and then enter the mixer 3, and then add fermentation bacteria, N nutrient salt and water to the mixer 3 through the batching machine 2 , mixed evenly and sent to solid organic matter aerobic pressurized high-temperature fermenter for fermentation, and finally the discharged material is used as feed or organic fertilizer or bio-organic fertilizer. The gas discharged from the aerobic pressurized high-temperature fermentation tank for solid organic matter ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com