Air sac type jack

A jack and airbag-type technology, applied in the direction of lifting devices, etc., can solve the problems of inability to take out the airbag-type jack, damage to operators and property, and high cost of raw materials for seamless pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

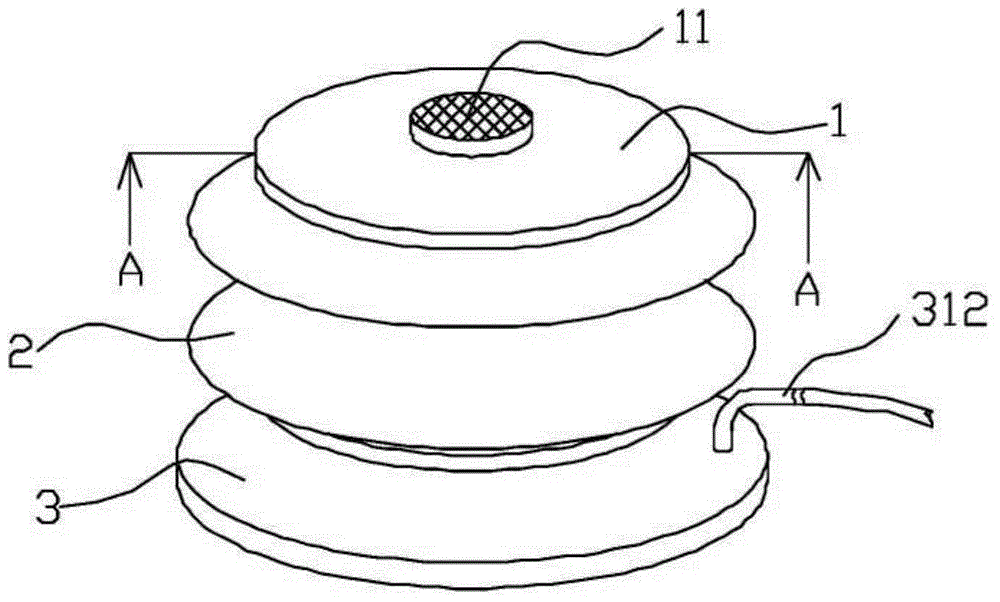

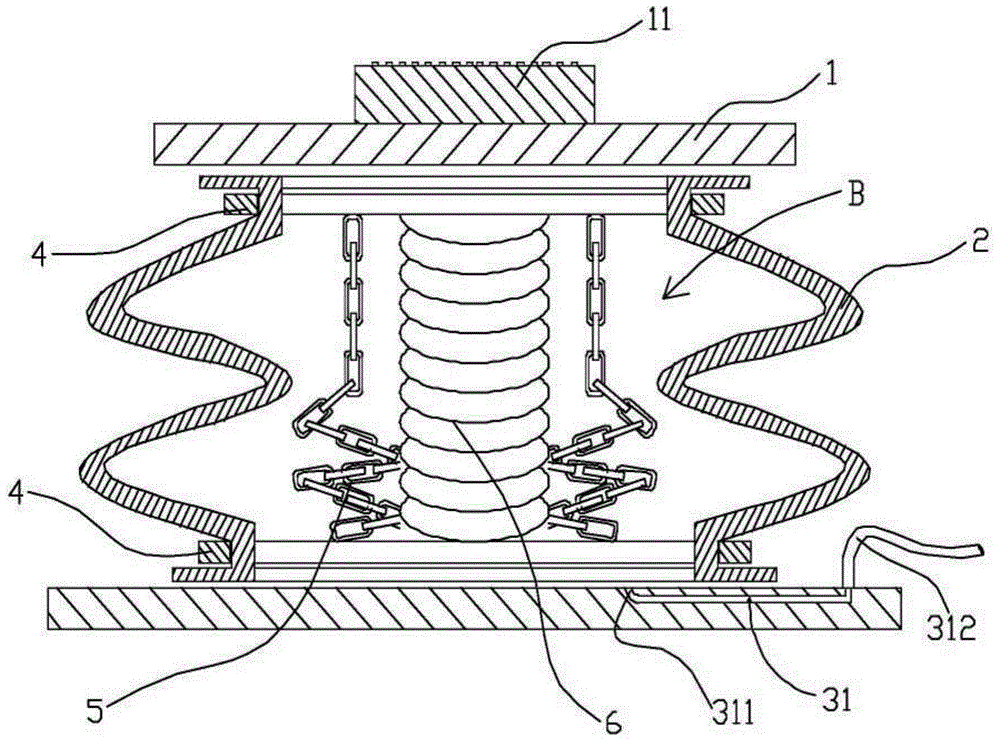

[0022] Figure 1 to Figure 3 A bladder jack according to one embodiment of the present invention is schematically shown. As shown in the figure, the device includes an upper top plate 1, a lower bottom plate 3, a rubber airbag 2 and a flange 4. The interior thus forms a closed pocket B.

[0023] A damping plate 11 is fixed on the upper top plate 1 .

[0024] The lower bottom plate 3 is connected with a high-pressure gas source through an air inlet pipe 312 . The lower bottom plate 3 is provided with an air inlet 31 , and the cavity B is provided with an air outlet 311 . The air inlet pipe 312 communicates with the air outlet 311 through the air inlet 31 .

[0025] A balance limiting device is also provided inside the cavity B.

[0026] In this embodiment, the balance limiting device is three iron chains 5 with the same length. The two ends of the iron chain 5 are fixedly connected with the upper top plate 1 and the lower bottom plate 3 respectively. Three iron chains 5 ...

Embodiment 2

[0030] Figure 4 A bladder jack according to another embodiment of the present invention is schematically shown. The difference from Embodiment 1 is that it also includes a strap 7. As shown in the figure, the strap 7 goes around the upper top plate 1 and is fixedly connected to the lower bottom plate 3 at both ends. In this embodiment, a hole for the strap 7 to pass is provided between the shock absorbing plate 11 and the upper top plate 1 . The strap 7 is not connected with the upper top board 1, and when the rubber air bag 2 rises, the strap 7 can slide on the upper top board 1, so that the purpose of keeping the upper top board 1 in a balanced state can be achieved. The binding belt 7 used in this embodiment is an industrial strong belt capable of bearing a force exceeding 2 tons.

[0031] In other embodiments, the balance limiting device can also be a strap 7 . When the airbag jack is working, the strap 7 slides on the upper top plate 1, which can also ensure that the ...

Embodiment 3

[0034] Figure 5 A bladder jack according to yet another embodiment of the present invention is schematically shown. The difference from Embodiment 1 is that it also includes a control rod 8 and a heightening pad 9 .

[0035] As shown in the figure, the heightening blocks 9 are placed on the upper top plate 1 to increase the lifting height of the airbag jack.

[0036] The control rod 8 is connected to the lower floor 3 and includes an armrest 82 and a hollow straight rod 81 . The armrest 82 is located at one end of the straight rod 81 . The other end of the straight rod 81 is provided with a small wheel 83 . The intake pipe 312 passes through the inside of the straight rod 81 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com