Automatic aluminum profile stacking device and control method thereof

An automatic technology for aluminum profiles, which is applied in the field of aluminum profiles before surface treatment, can solve the problems of potential safety hazards, large manpower consumption, and uneven spacing between pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

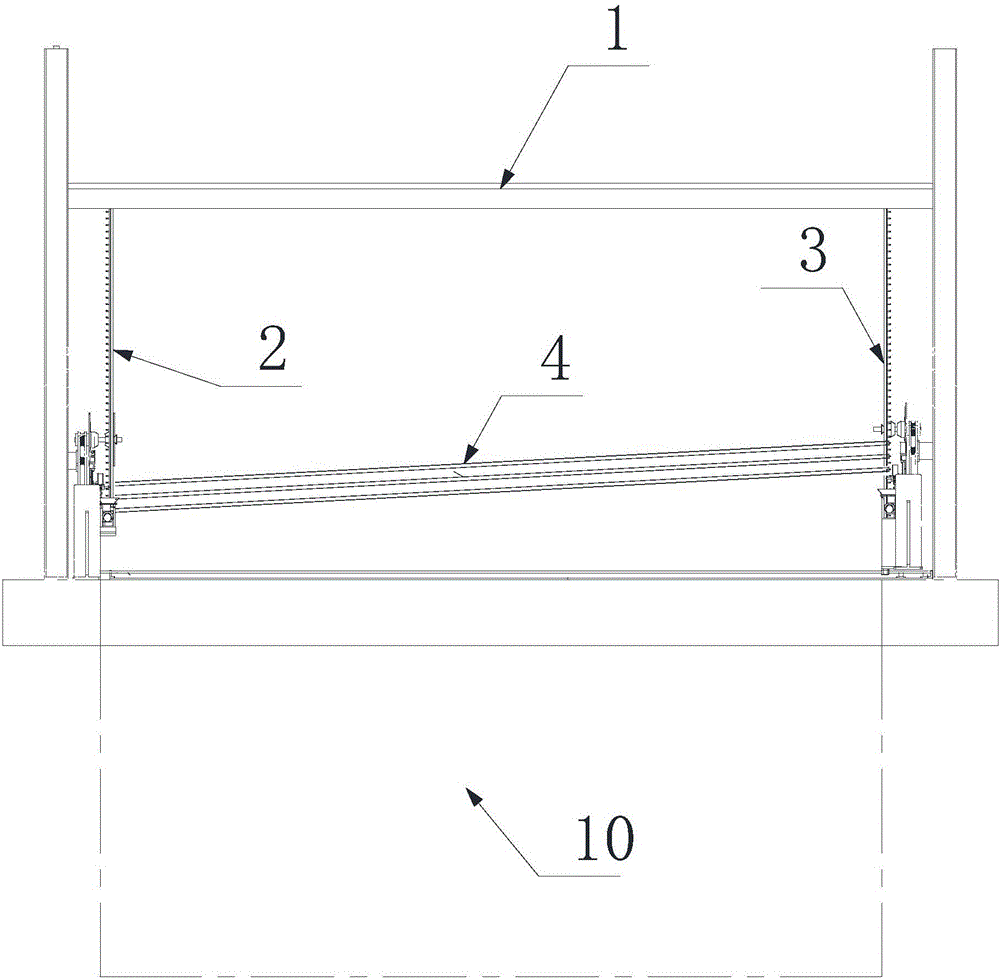

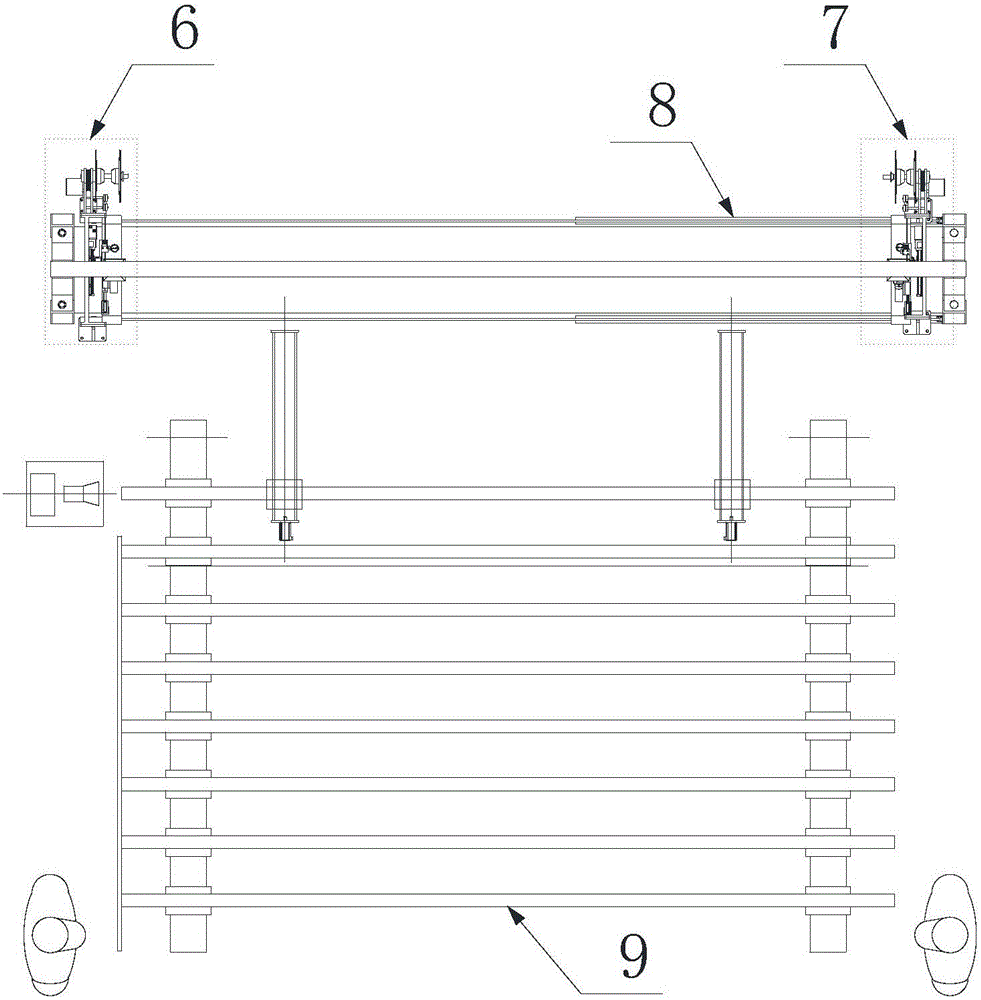

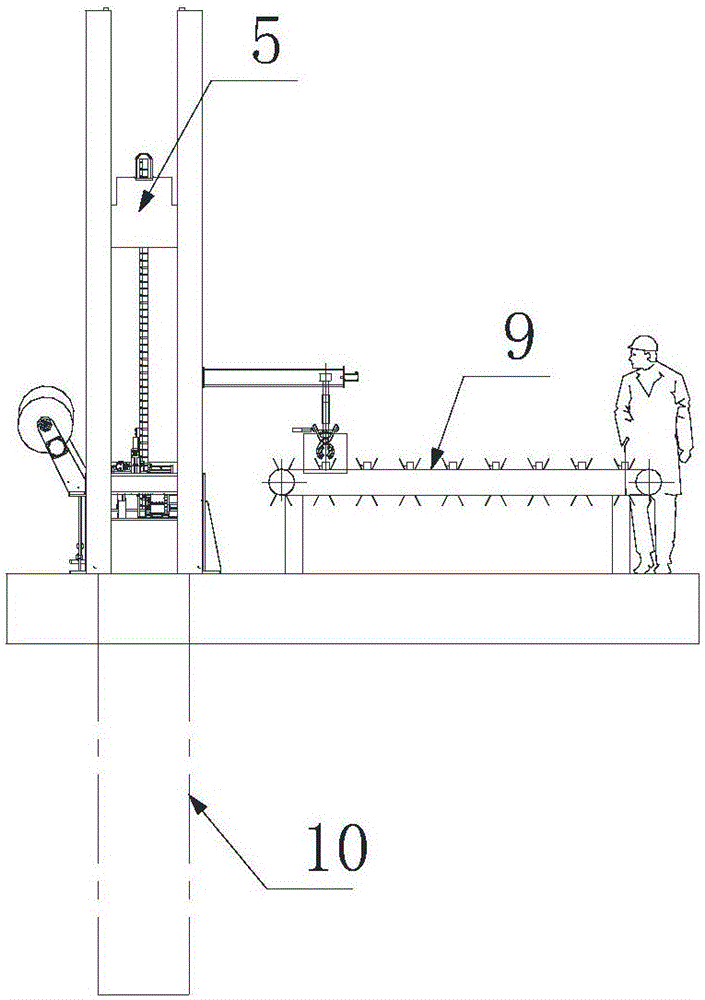

[0066] see figure 1 , 2 , 3, the present embodiment is a kind of automatic upper row device for aluminum profiles, including aluminum profile feeding unit 9, winding unit, conductive frame lifting unit 5, winding machine translation mechanism 8 and conductive rods (including left conductive rod 2 and right conductive rod 3), the aluminum profile feeding unit 9 is arranged on one side of the winding unit, and is used to transport the aluminum profiles 4 to the front end of the winding unit in an orderly manner. The winding unit includes two winding machines (respectively left winding machine 6 and right winding machine 7 ), a winding machine is arranged on the side of each conductive rod, and the two winding machines are arranged on the translation mechanism 8 of the winding machine, and the distance between them is adjustable. The conductive frame lifting unit 5 is used for automatically lifting the conductive rod after an aluminum profile is wound tightly. In this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com