Container and manufacturing method thereof

A production method and container technology, applied in the field of containers, can solve the problems of reduced container load capacity, high container production cost, and improved container body, so as to achieve the effects of saving resources, simplifying the production process, and increasing the load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

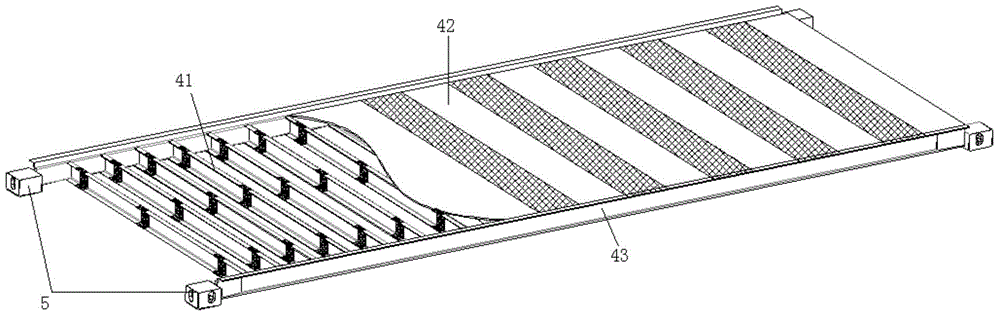

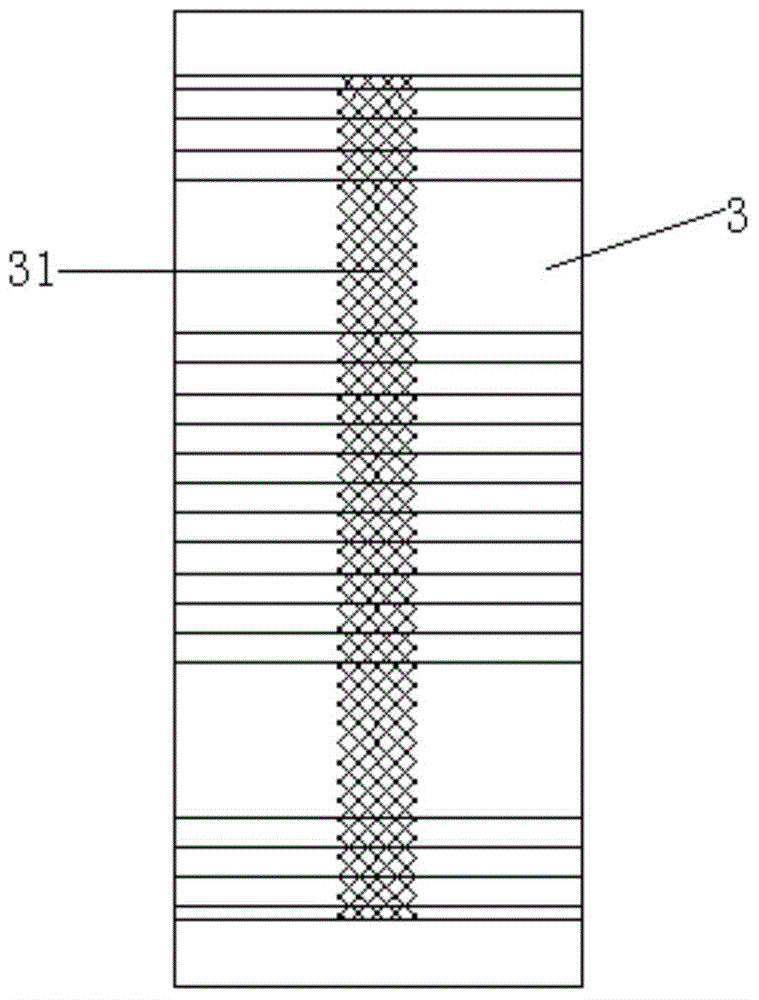

[0048] The container of the present invention comprises a bottom frame, a door end plate and a front end plate respectively set up at both ends of the bottom frame in the length direction, a pair of side plates respectively set up on both sides of the bottom frame in the width direction, and horizontally arranged on the door end plate, the front end plate and the front end plate. The top plate at the top of the side plate, the underframe includes two bottom side beams parallel to each other, two front and rear end beams parallel to each other, a plurality of bottom beams transversely connected to the two bottom side beams, and a bottom beam laid on the bottom beams For the floor, the wall thickness of the door end plate 3 changes regularly in its length or width direction, and its thin-walled area 31 is distributed at intervals with thick-walled areas, such as image 3shown. The thick-walled area can be arranged along the length or width of the centerline of the door end plate...

Embodiment 2

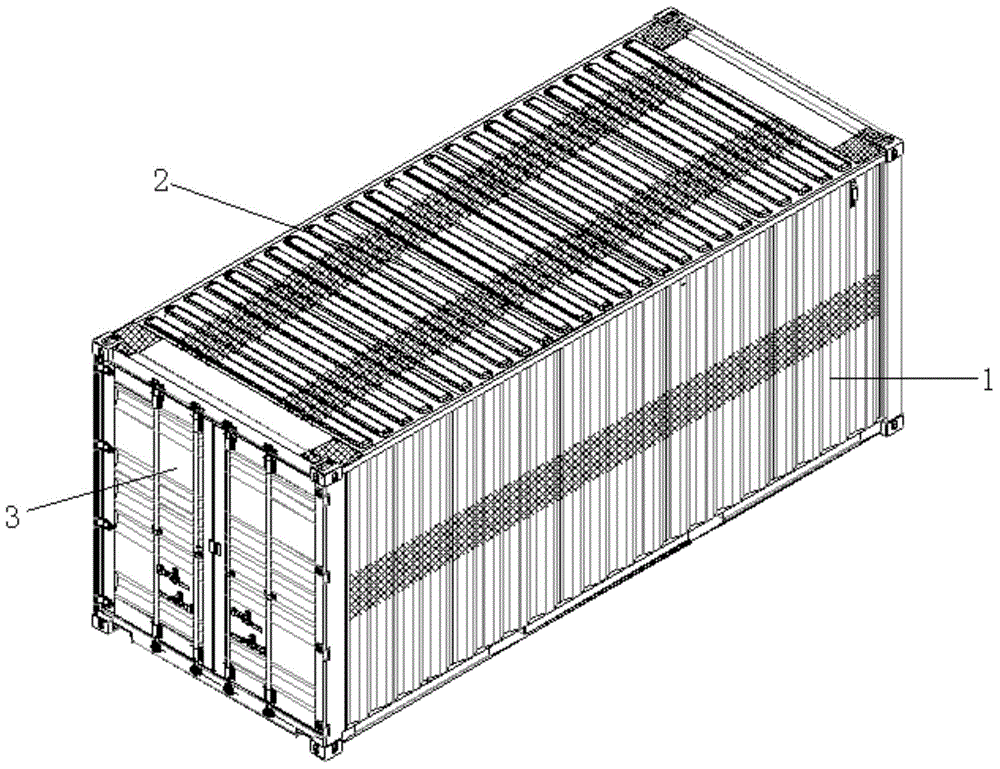

[0050] The container of the present invention comprises a bottom frame, a door end plate and a front end plate respectively set up at both ends of the bottom frame in the length direction, a pair of side plates 1 respectively set up on both sides of the bottom frame in the width direction, and horizontally arranged on the door end plate and the front end plate. and the top plate at the top of the side plate 1, the underframe includes two bottom side beams parallel to each other, two front and rear end beams parallel to each other, a plurality of bottom beams transversely connected to the two bottom side beams and laying on the bottom beams On the floor, the wall thickness of the side plate 1 changes regularly in the direction of its length or width, and its thin-walled area 11 and thick-walled area are distributed at intervals, such as Figure 4 shown. The thick-walled area can be arranged along the long or wide centerline of the side panel 1 , or can be arranged at other part...

Embodiment 3

[0052] The container of the present invention comprises a bottom frame, a door end plate and a front end plate respectively set up at both ends of the bottom frame in the length direction, a pair of side plates respectively set up on both sides of the bottom frame in the width direction, and horizontally arranged on the door end plate, the front end plate and the front end plate. The top plate at the top of the side plate, the underframe includes two bottom side beams parallel to each other, two front and rear end beams parallel to each other, a plurality of bottom beams transversely connected to the two bottom side beams, and a bottom beam laid on the bottom beams For the floor, the wall thickness of the front plate varies regularly in the direction of its length or width, and its thin-walled areas and thick-walled areas are distributed at intervals. The thick-walled area can be arranged along the long or wide centerline direction of the front end plate, and can also be arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com