Permanent-magnet maglev train

A magnetic levitation train and permanent magnet technology, applied in the direction of motor vehicles, electric vehicles, railway vehicles, etc., can solve the problems of complex structure and control, unstable performance, large power consumption, etc., and achieve low operating cost, high acceleration, and high speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

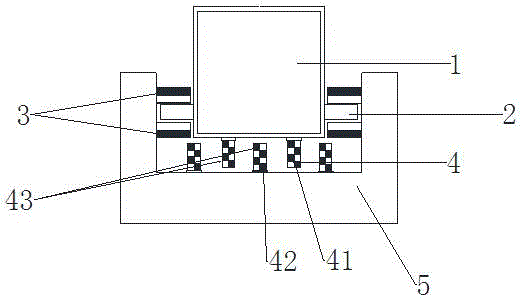

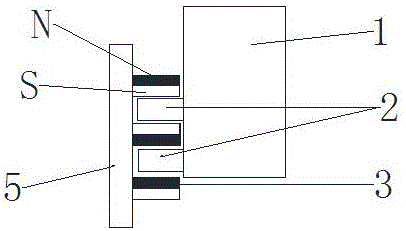

[0028] A permanent magnetic maglev train, comprising a carriage 1, a magnet drive wheel 2, a guide rail 3, a buoyancy frame 4 and a track pit 5, the magnet drive wheel 2 is horizontally arranged on both sides of the carriage 1, and the guide rail 3 is arranged on the magnet The upper and lower sides of the drive wheel 2; the buoyancy frame 4 includes a car buoyancy frame 41 and a land-based buoyancy frame 42;

[0029] The carriage buoyancy frame 41 is arranged at the bottom of the carriage 1, the subgrade buoyancy frame 42 is arranged at the bottom of the track pit 5, and the guide rail 3 is arranged on the inner walls of both sides of the track pit 5;

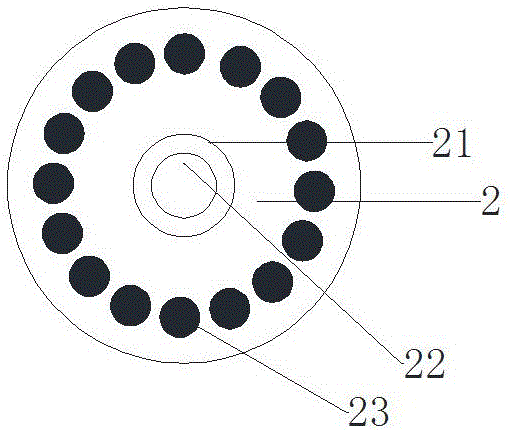

[0030] The compartment 1 is a box structure, the magnet drive wheel 2 is disc-shaped, and a bearing 21 is arranged in the middle of the magnet drive wheel 2; it is connected with the compartment 1 through a rotating shaft 22; the magnet drive wheel 2 is inlaid with Several cylindrical permanent magnets 23; the cylindrical perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com