Environment-friendly papermaking process

A kind of papermaking technology and environment-friendly technology, which is applied in the field of environment-friendly papermaking technology, can solve the problems of paper quality degradation and inability to separate, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

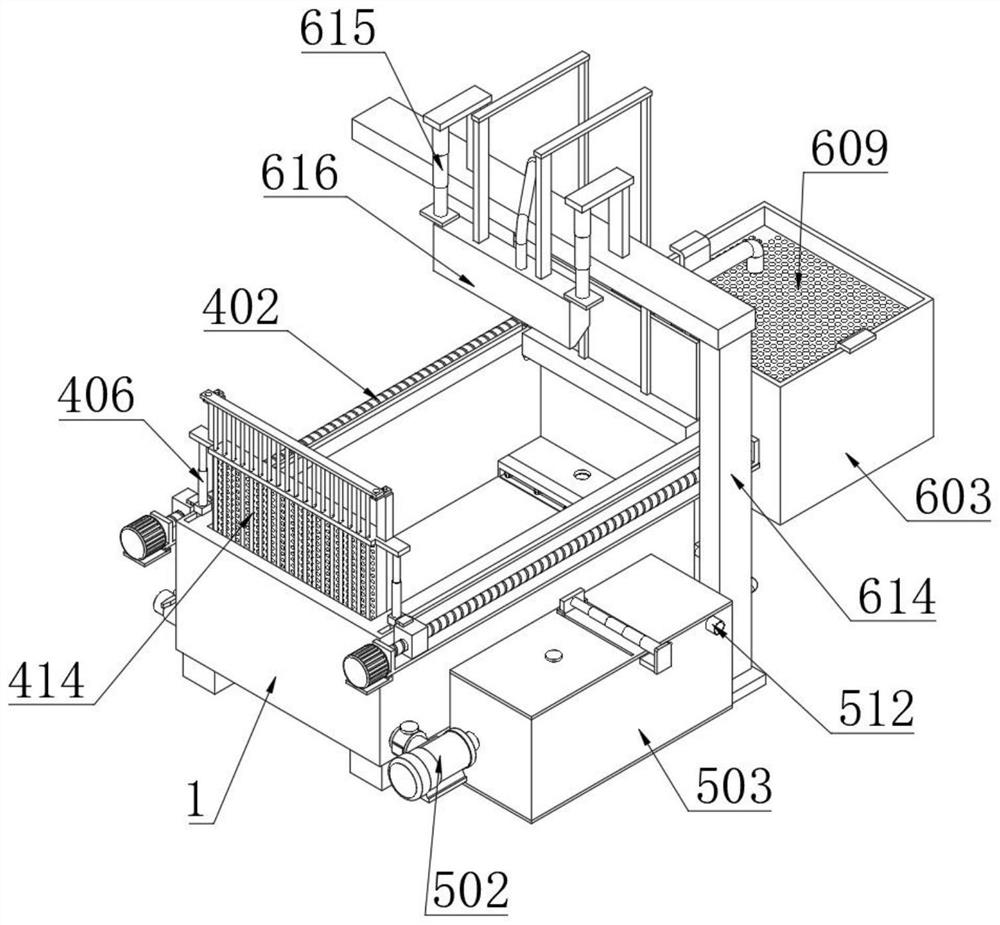

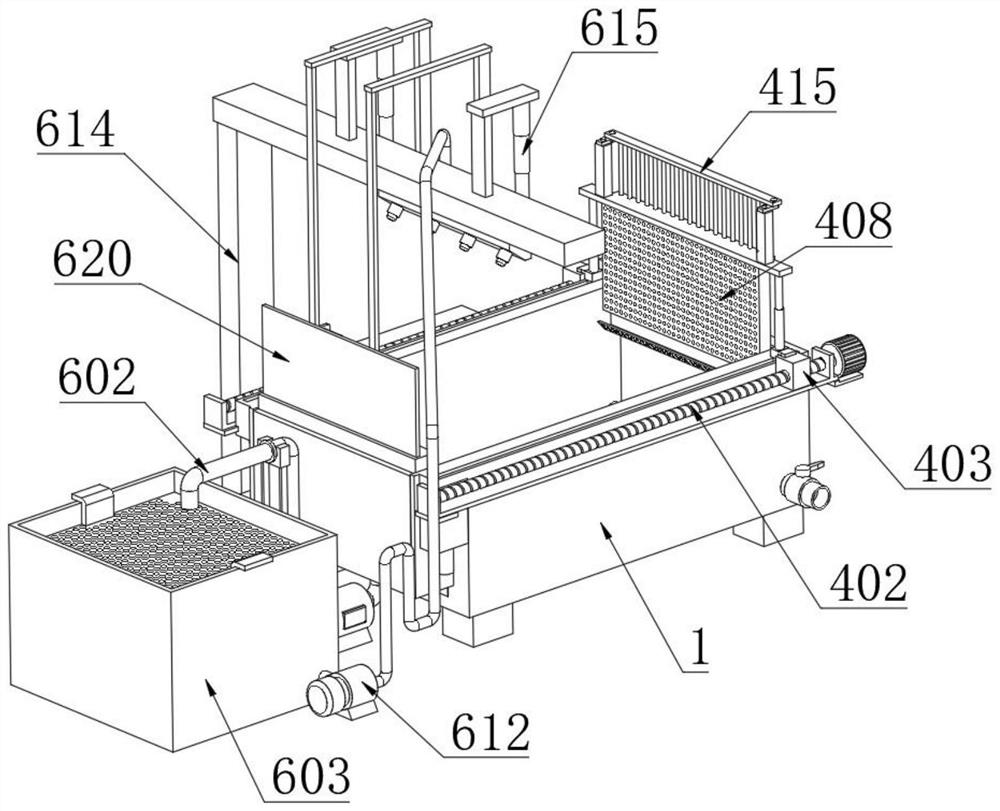

[0042] Example: figure 1 As shown, the present invention provides a technical solution, an environmentally friendly papermaking process, including the steps of:

[0043] S1: Mix: Inject the pulp and mixed water into the inside of the precipitated tank 1, loosen the fixation of the vertical rod 414 such that the vertical rod 414 is inserted inside the pulp, vertical round rod 414 with the guide block 405 The pulp is mixed forward, so that the ink and particulate impurities can be floated and sinking;

[0044] S2: Separation: Re-fixing the vertical rod 414 on top of the vertical rod 412, the hydraulic telescopic rod 406 drops below the liquid surface, the ink filter plate 409 will float in the top of the pulp when moving when the guiding block 405 moves Ink impurities push forward, separated from pulp;

[0045] S3: Push: Hydraulic telescopic rod 406 drives the pulp filter plate 408 to fall into the inside of the pulp, and the pulp filter plate 408 will push the floated pulp forwardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com