Polyester packaging film having parallel openings and manufacture method of polyester packaging film

A technology of parallel opening and packaging film, which is applied in the field of polyester film, can solve the problems of not being easy to tear, and achieve the effects of reducing track retraction rate, improving transverse orientation degree, and reducing longitudinal stretch ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

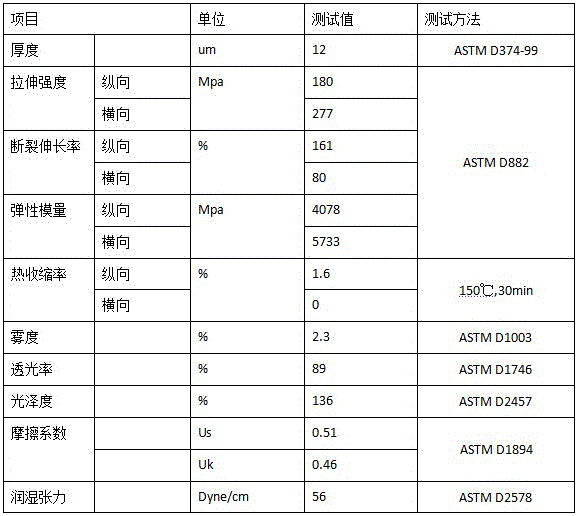

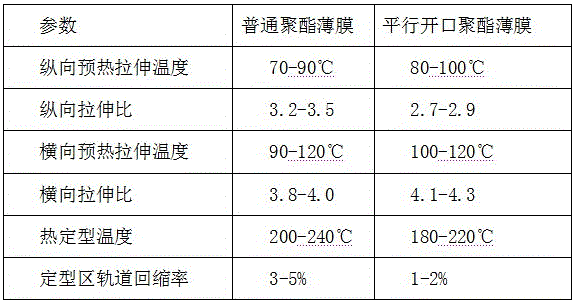

[0021] Embodiment 1. A parallel opening polyester packaging film with a thickness of 12um is prepared by three-layer co-extruded biaxially stretched production equipment at a production speed of 240m / min. It consists of upper and lower surface layers and a core layer.

[0022] The thickness of the core layer is 9um, 80% fresh bright polyester chips and 20% recycled chips; the thickness of both surface layers is 1.5um, 50% fresh bright polyester chips, 50% fresh silicon-containing polyester chips (Silicon dioxide concentration: 3000ppm, particle size 3.5um).

[0023] The production process of this example mainly includes the following steps:

[0024] A. Preparation of the core layer: Mix the fresh bright polyester chips and recycled chips of the core layer with a good ratio, pass through the fluidized bed at a temperature of 170°C for 15-20 minutes and enter the drying tower, and in the drying tower at a temperature of 160°C Drying at temperature for 4-5 hours to obtain dry ra...

Embodiment 2

[0033] Example 2: A parallel opening polyester packaging film with a thickness of 19um is prepared by three-layer co-extruded biaxially stretched production equipment at a production speed of 200m / min, consisting of upper and lower surface layers and a core layer.

[0034] The thickness of the core layer is 15um, 75% fresh bright polyester chips and 25% recycled chips; the thickness of both surface layers is 2um, 55% fresh bright polyester chips, 45% fresh silicon-containing polyester chips ( Silica concentration: 3000ppm, particle size 3.5um).

[0035] The production process of this example mainly includes the following steps:

[0036] B. Preparation of the core layer: mix the fresh bright polyester chips and recycled chips of the core layer with a good ratio, pass through the fluidized bed at a temperature of 170°C for 15-20 minutes and enter the drying tower, and in the drying tower at a temperature of 160°C Drying at temperature for 4-5 hours to obtain dry raw materials; ...

Embodiment 3

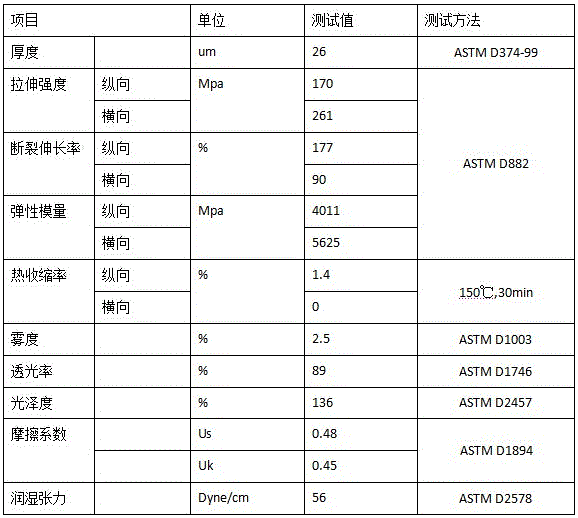

[0045] Example 3: A parallel opening polyester packaging film with a thickness of 26um is prepared by three-layer co-extruded biaxially stretched production equipment at a production speed of 160m / min, consisting of upper and lower surface layers and a core layer.

[0046] The thickness of the core layer is 21um, 70% fresh bright polyester chips and 30% recycled chips; the thickness of both surface layers is 2.5um, 60% fresh bright polyester chips, 40% fresh silicon-containing polyester chips (Silicon dioxide concentration: 3000ppm, particle size 3.5um).

[0047] The production process of this example mainly includes the following steps:

[0048] C. Preparation of the core layer: Mix the fresh bright polyester chips and recycled chips of the core layer with a good ratio, pass through the fluidized bed at a temperature of 170°C for 15-20 minutes and enter the drying tower, and in the drying tower at a temperature of 160°C Drying at temperature for 4-5 hours to obtain dry raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com