Manufacturing method for injection molding alloy material hollowed-out checkered plate

An alloy material and injection molding technology, applied in the field of machinery, can solve the problems of wood materials being not resistant to acid and alkali, wood being easily corroded by fungi, and large waste, so as to reduce the labor intensity of workers, the manufacturing process is simple and fast, and the requirements for personnel skills are reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

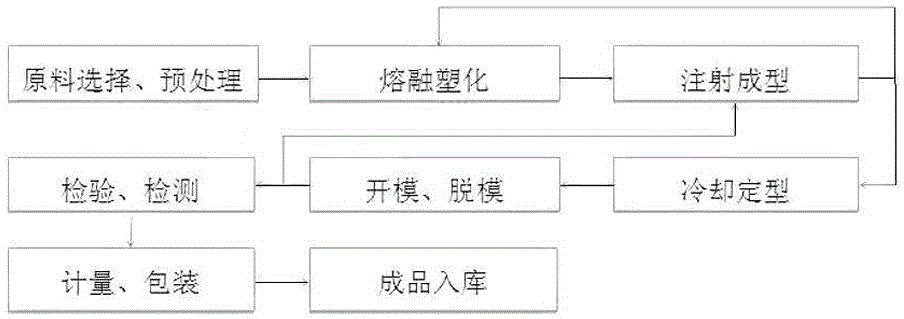

Method used

Image

Examples

specific Embodiment 1

[0048] Preheat the alloy material at 60 degrees Celsius for 2 hours. The temperature of each zone of the injection molding machine is 100, 140, 180, 220 and 260 degrees Celsius. After heating to the molten state, the molten alloy material is injected under the conditions of 110MPa pressure and 85% flow rate Injection into the mold by means of injection; after the mold injected with the alloy material is cooled, it is demolded as a whole to obtain a hollow grille plate.

specific Embodiment 2

[0050] Preheat the alloy material at 65 degrees Celsius for 1.5 hours. The temperature of each zone of the injection molding machine is 100, 130, 140, 160, 200, and 240 degrees Celsius. Inject into the mold by injection under the condition of 90%; after the mold injected with the alloy material is cooled, it is demoulded as a whole, and the hollow grille plate is obtained.

specific Embodiment 3

[0052] Preheat the alloy material at 65 degrees Celsius for 1.5 hours. The temperature of each zone of the injection molding machine is 100, 130, 160, 200, and 240 degrees Celsius. After heating to the molten state, the molten alloy material is injected under the conditions of 90MPa pressure and 90% flow rate Injection into the mold by means of injection; after the mold injected with the alloy material is cooled, it is demolded as a whole to obtain a hollow grille plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com