Solid wood bed machining equipment

A technology of processing equipment and solid wood, which is applied in the direction of wood processing equipment, sawing equipment, manufacturing tools, etc., can solve the problems of inconvenient feeding and affect the production efficiency of enterprises, and achieve the effect of simple structure, easy maintenance and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

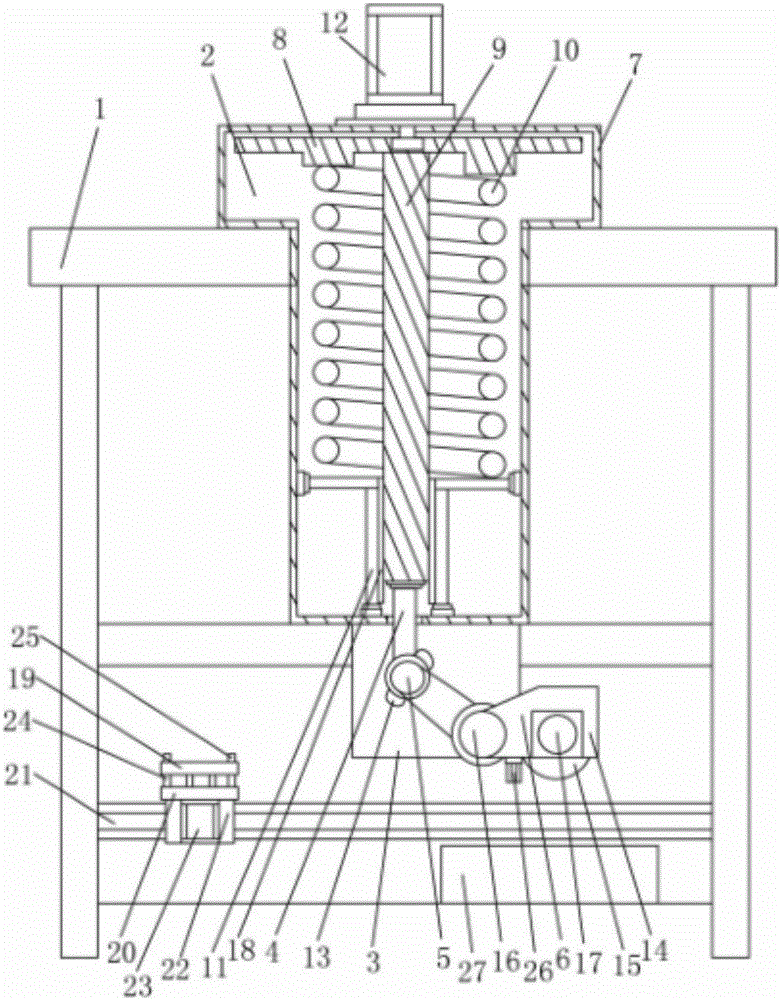

[0023] like figure 1 As shown, a solid wood bed processing equipment includes a frame 1, a cutting knife control mechanism 2, a cutting knife fixing seat 3, a telescopic rod connecting rod 4, a telescopic rod connecting rod rotating shaft 5, a cutting knife mechanism 6, and a feed upper splint 19 , feed lower splint 20, splint guide rail 21, lower splint movement mechanism 22, feed lower splint cylinder 23, first limit post 24, second limit post 25, brush 26, sawdust collection box 27, cutting knife control Mechanism 2 includes shell 7, spring compression plate 8, telescopic rod 9, spring 10, telescopic rod limit frame 11, shell cylinder 12, shell 7 is installed on the frame 1, spring compression plate 8, telescopic rod 9, spring 10, The telescopic rod limit frame 11 is located inside the shell 7, the spring compression plate 8 is connected with the telescopic rod 9, the shell cylinder 12 is installed on the shell 7 and its piston rod end is connected with the spring compressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com