Meat cutter

The technology of a meat slicer and rack is applied in the direction of processed meat, meat processing equipment, metal processing, etc. It can solve the problems of troublesome cleaning, difficult cleaning, and continuous cutting of meat, so as to ensure the effect of meat cutting, simple cleaning and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

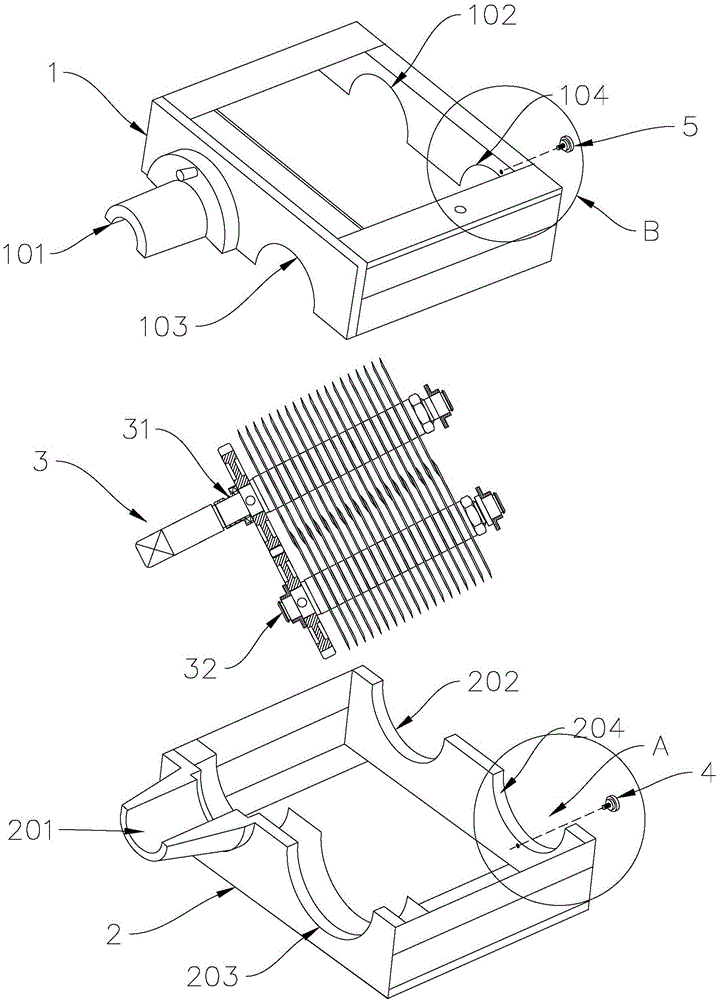

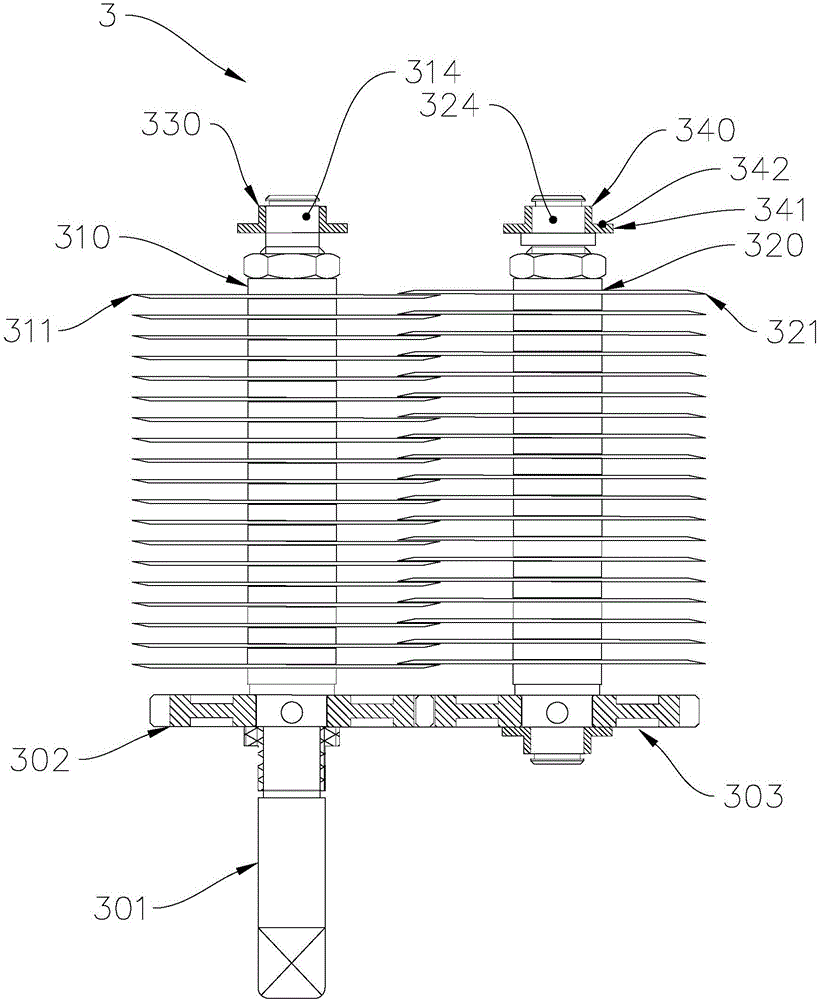

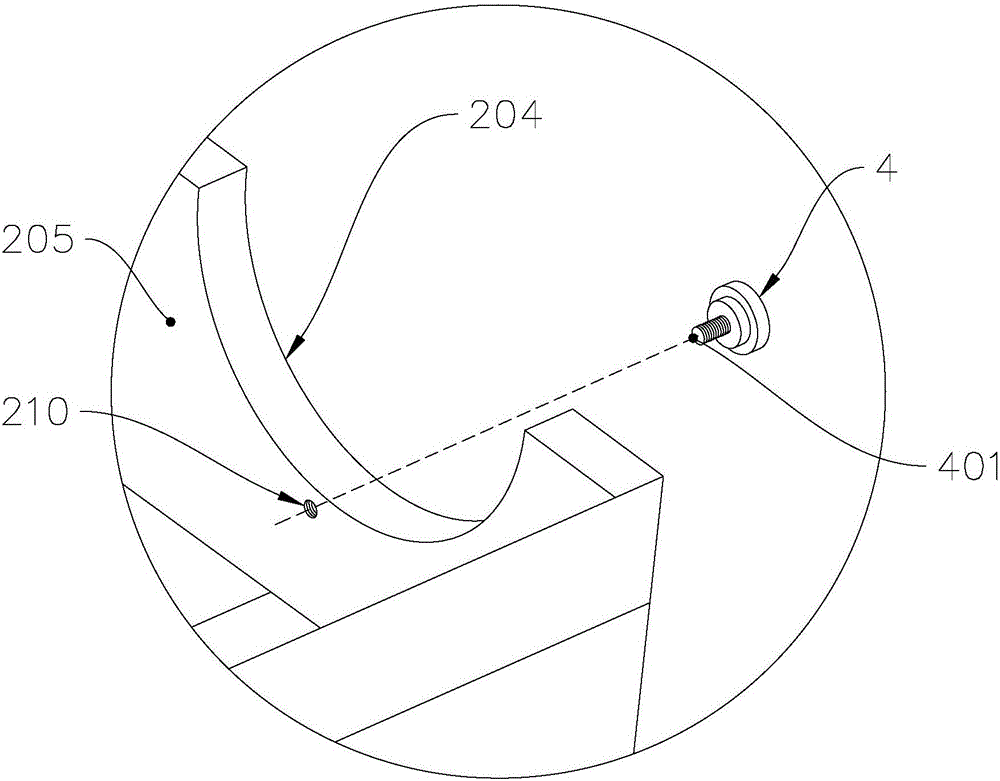

[0026] The meat cutting machine of the present invention includes a frame and a cutter group installed in the frame, and a cutting edge area is formed between two blades on the cutter group so that the meat piece entering from the feed port is cut into pieces by the cutter group. Strip or sheet, and then sent out from the outlet of the rack.

[0027] see figure 1 , figure 1 It is an exploded view of the structure of the meat slicer. The frame includes an upper frame 1 and a lower frame 2, and the upper frame 1 and the lower frame 2 are jointly combined into a frame for positioning the cutter group 3. The upper frame 1 is similar in structure to the lower frame 2. The upper frame 1 is an open cover with connecting walls all around. Mounting positions are arranged on both side walls of the upper frame 1. The mounting positions on the upper frame 1 include The input shaft limiting part 101 , the driving shaft limiting part 102 , the driven shaft first limiting part 103 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com