A method of inner hole grinding using fully automatic numerical control internal grinding

An internal grinding and fully automatic technology, which is applied to the cleaning method using liquid, the parts of the grinding machine tool, and the machine tool designed for grinding the rotating surface of the workpiece. Advanced problems, to achieve the effect of high processing efficiency of the inner hole, improve the degree of automation, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

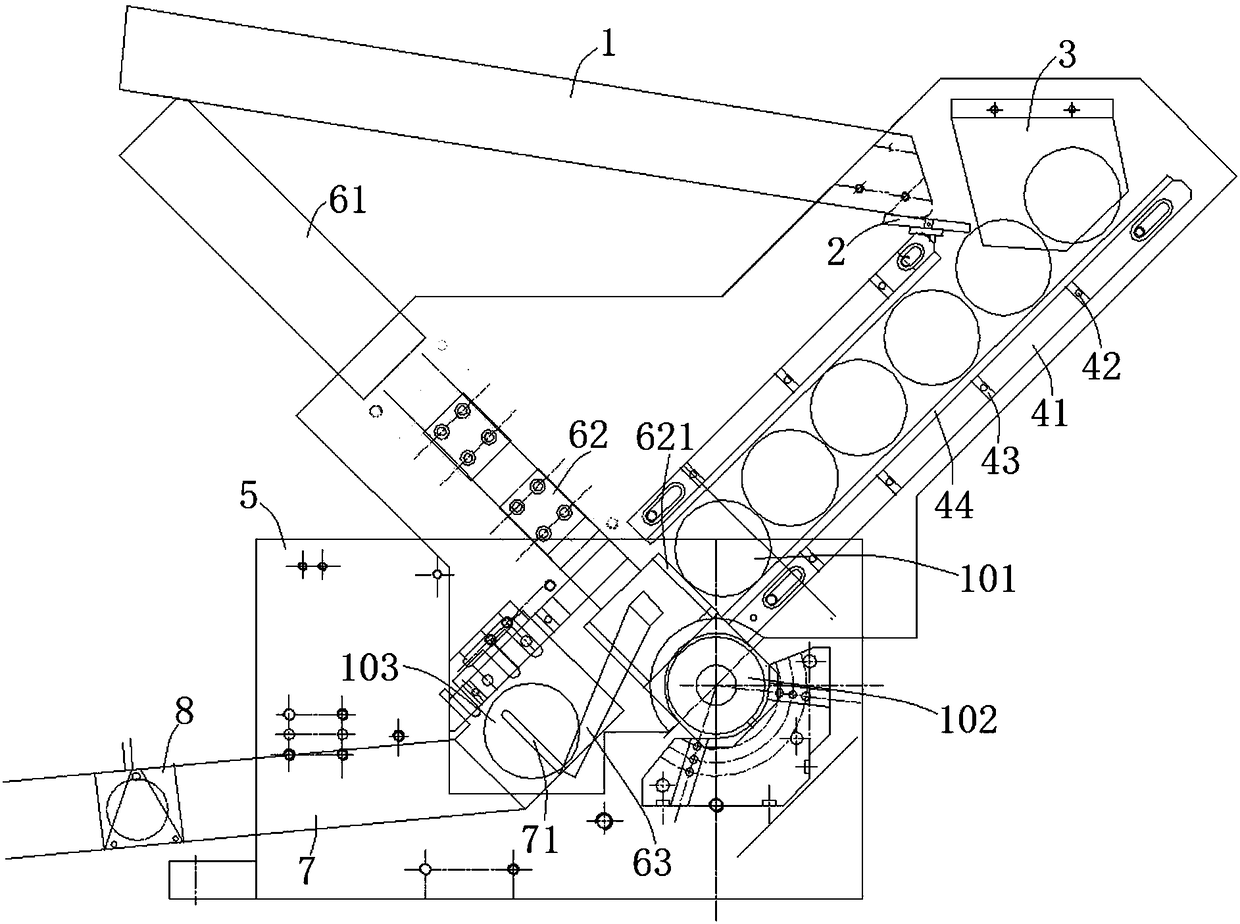

[0042] to combine figure 1 , a kind of full-automatic numerically controlled internal grinding of the present embodiment, comprises feeding channel 1, workpiece pushing mechanism, discharging channel 7 and inner hole size measuring mechanism, feeding channel 1, workpiece pushing mechanism, discharging channel 7 are all set On the internal grinding box body 5. in:

[0043] The feeding channel 1 is divided into two sections arranged at a certain angle, and a transfer block 3 is arranged between the two sections of the feeding channel 1 . The purpose of setting the feeding channel 1 in two sections is to ensure that the inlet of the feeding channel 1 and the outlet of the feeding channel 7 face the staff at the same time, so that the staff can complete the loading and unloading operations at one station, saving time and effort. The function of the transfer block 3 is mainly to change the falling direction of the workpiece 101 to be ground so that it falls into the workpiece pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com