Automatic production technology of fabricated building blocks

A production technology and assembly technology, which can be used in supply devices, ceramic molding workshops, auxiliary molding equipment, etc., and can solve the problems of blank collision, difficulty in ensuring molding and consistent mechanical properties under pressure, and material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] With reference to the figures covered in the accompanying drawings and specific practical instructions are as follows:

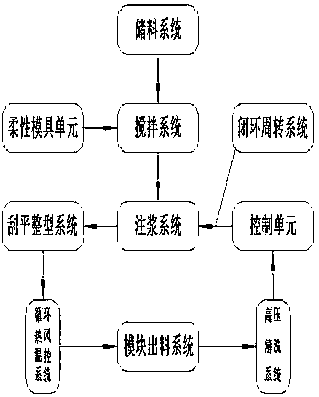

[0019] As shown in the figure, the automatic production technology of prefabricated blocks consists of material storage system, mixing system, grouting system, closed-loop turnover system, scraping and leveling system, circulating hot air temperature control system, high-pressure cleaning system, flexible mold unit, module Composed of a discharge system and a control unit, the storage system can be installed in the open air according to the installation environment. The storage system is composed of multiple storage tanks, and a metering control unit is installed inside to control the raw materials, and the raw materials are transported through metering output. To the mixing system, a water metering control unit, a uniform stirring device and a metering device are installed in the mixing system, and the slurry is transported to the grouting system thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com