CNC engraving and milling machine with built-in loading and unloading device

A technology of engraving machines and fixtures, which is applied in the field of engraving machines, can solve the problems of operators affecting their health and the environment of production workshops, and achieve the effects of saving labor costs, reducing the impact of failure rates, and preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

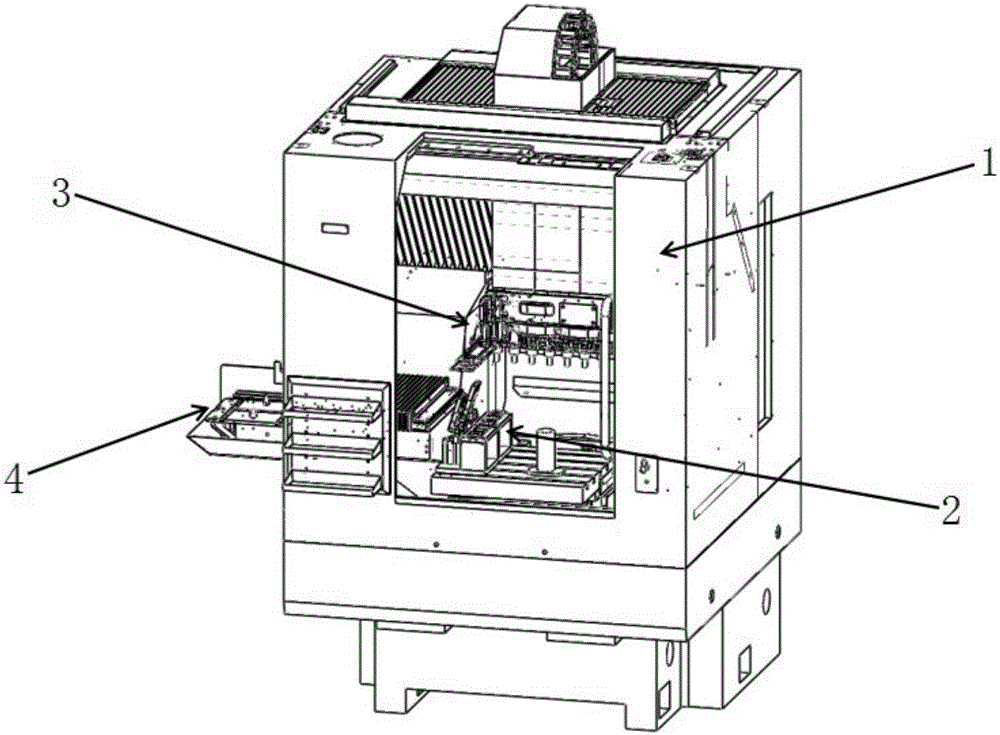

[0035] The invention provides a fine carving machine with a loading and unloading device inside the machine, such as figure 1 As shown, it includes the main body 1 of the Jingdiao machine. The main body 1 of the Jingdiao machine adopts the master machine of the Jingdiao machine of the Caver400TE-A10E model; It is fixedly connected on the machine head part 5; the bottom of the loading and unloading mechanism 3 in the machine is provided with a jig mechanism 2, and the jig mechanism 2 is adjacent to the hopper mechanism 4; The outer part and the inner part of the main body 1 of the Jingdiao machine.

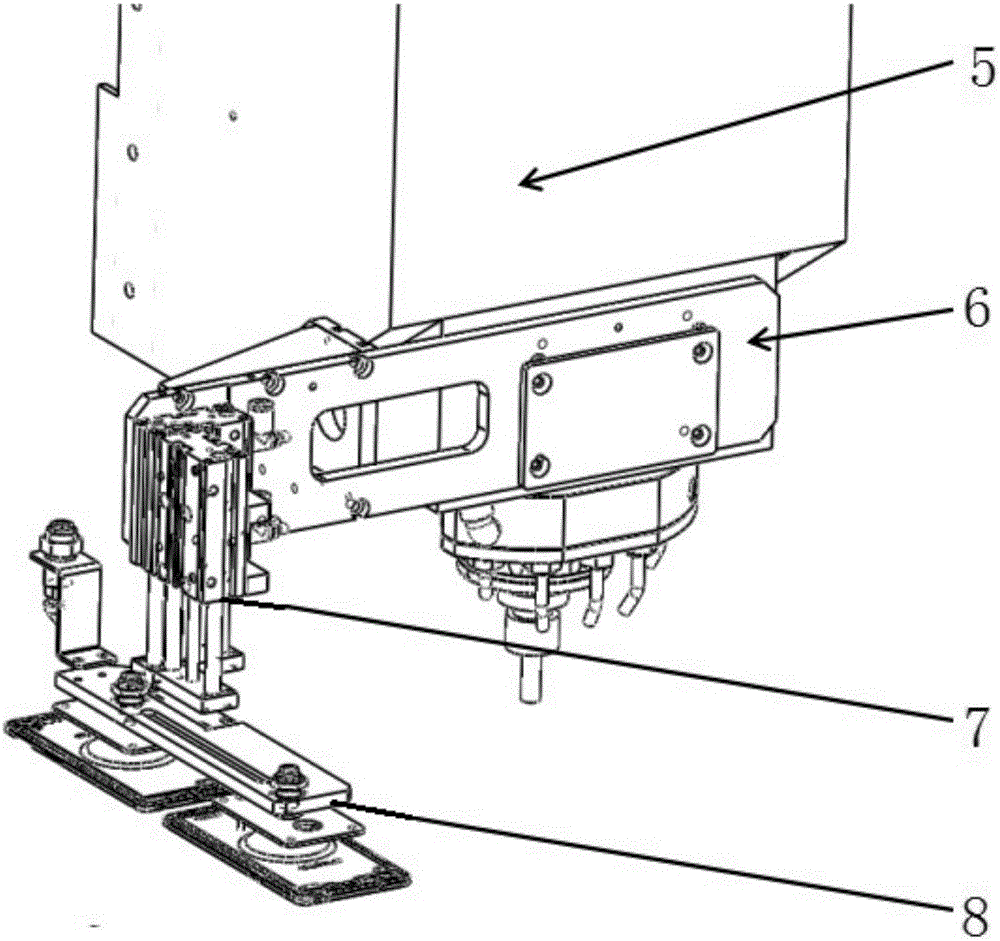

[0036] Such as figure 2 As shown, the loading and unloading mechanism 3 in the machine includes a suction cup assembly 8, which is connected to the guide rod cylinder 7, and the guide rod cylinder 7 is connected to the head part 5 by installing the connecting plate 6.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com