Tapping device for stop ring of clutch machine cover

A technology of tapping device and stop ring, which is applied in the direction of driving device, positioning device, metal processing mechanical parts, etc., can solve the problem of not being able to automatically process annular parts, avoid low precision of manual operation, simplify the operation process, and improve the processing efficiency. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

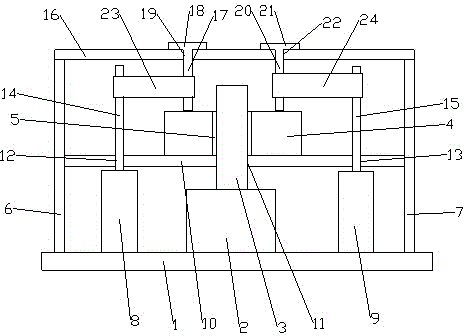

[0011] In the figure: 1-base, 2-rotating motor, 3-rotating shaft, 4-stop ring, 5-anti-skid pad, 6-first supporting column, 7-second supporting column, 8-first processing motor, 9 -Second processing motor, 10-bracket, 11-rotary slot, 12-first limit hole, 13-second limit hole, 14-first processing axis, 15-second processing axis, 16-support Plate, 17-drill shaft, 18-drill shaft limit block, 19-first round hole, 20-tap, 21-tap limit block, 22-second round hole, 23-first timing belt, 24-the first Two timing belts.

[0012] This embodiment includes a base 1, a rotating motor 2 is arranged on the base 1, a rotating shaft 3 is arranged on the top of the rotating motor 2, a stop ring 4 is set on the outside of the rotating shaft 3, and a stop ring 4 is provided between the rotating shaft 3 and the stop ring 4. Anti-slip mat 5, base 1 is also provided with first support column 6, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com