Rotary mechanism and method for processing sheet metal parts

A technology of rotating mechanism and sheet metal parts, applied in metal processing mechanical parts, metal processing, metal processing equipment and other directions, can solve the problems of easy deviation of processing position and complicated operation, and achieve simple and convenient use process and small angle. Adjusting, avoiding loosening and shedding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

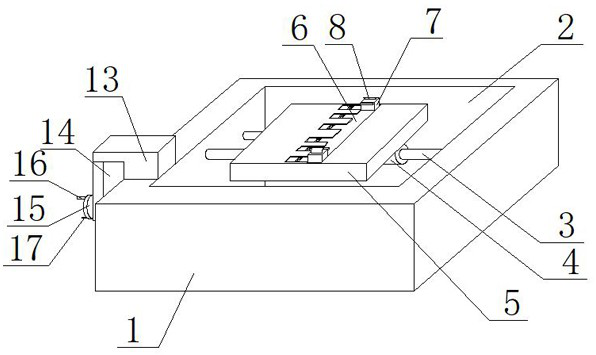

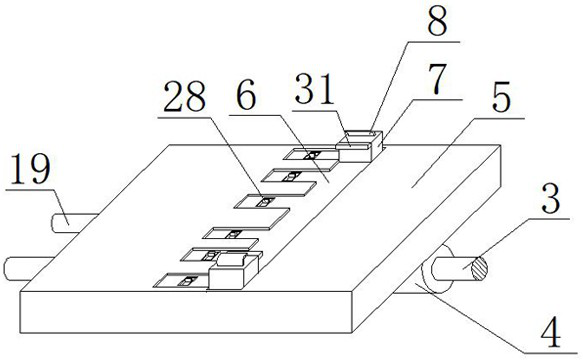

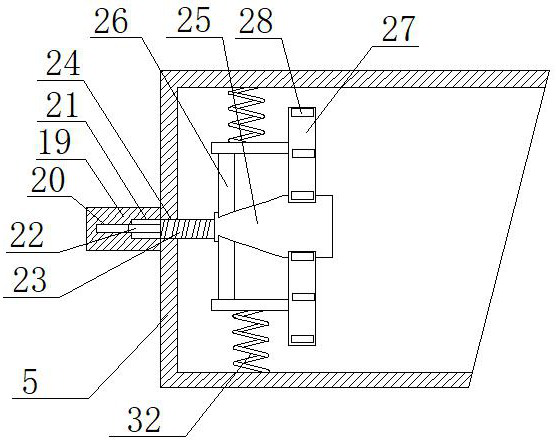

[0029] refer to Figure 1-6, a rotating mechanism for sheet metal parts processing, comprising a base plate 1, a movable groove 2 is provided on the base plate 1, a rotating column 3 is installed on the inner wall of the movable groove 2, and a fixed sleeve 4 is provided on the fixed sleeve of the rotating column 3, and the fixed sleeve 4 is fixedly installed with a rotating plate 5, the rotating plate 5 is a hollow structure, and the top of the rotating plate 5 is provided with a first chute 6, and two sliding seats 7 are slidably installed in the first chute 6, and the first chute 6 It is formed by connecting multiple slots together, including a long slot for moving the sliding seat 7 and several short slots for fixing the sliding seat 7, two sliding seats 7 are provided with splints 8, and one part of the bottom plate 1 One end of the rotating rod 10 is installed for side rotation, and the other end of the rotating rod 10 is fixedly equipped with a turntable 15, and a rocke...

Embodiment 2

[0039] refer to Figure 1-6 , a rotating mechanism for sheet metal parts processing, comprising a base plate 1, a movable groove 2 is provided on the base plate 1, a rotating column 3 is installed on the inner wall of the movable groove 2, and a fixed sleeve 4 is provided on the fixed sleeve of the rotating column 3, and the fixed sleeve 4 is welded with a rotating plate 5, the rotating plate 5 is a hollow structure, and the top of the rotating plate 5 is provided with a first chute 6, and two sliding seats 7 are slidably installed in the first chute 6, and the first chute 6 is A plurality of slots are connected together to form, including a long slot for moving the sliding seat 7 and several short slots for fixing the sliding seat 7, two sliding seats 7 are provided with splints 8, one side of the bottom plate 1 Rotate one end of the rotating rod 10, the other end of the rotating rod 10 is welded with a turntable 15, the turntable 15 is welded with a rocker 16, the rocker 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com