A magnetically cooled non-vibration pump body and end cover dynamic clamping drilling equipment

A technology for drilling equipment and water pumps, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., and can solve the problems of single use of water pump drilling devices, fixed clamping, unevenness, etc. Achieve the effect of facilitating automatic rotation processing, prolonging service life, and efficient drilling processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of this patent will be described in further detail below in conjunction with the specific implementation. The technical features or connection relationships described in the present invention are not described in detail. They are all existing technologies adopted.

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

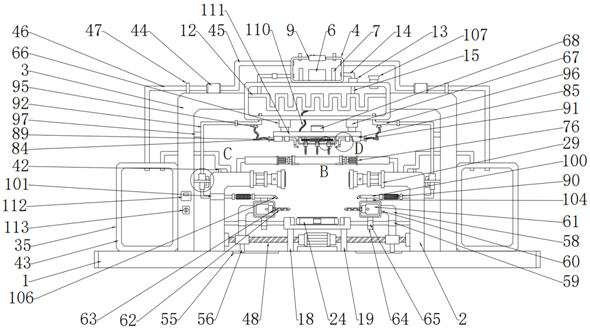

[0032] Such as figure 1 As shown, the magnetic-cooled non-vibration water pump body and the end cover of the present invention are dynamically clamped and drilled, including a bottom plate 1, an embedded support plate 2, an externally embedded support plate 3, a rapid response refrigeration mechanism 4, and a non-powered Angle rotation mechanism 18, adaptive clamping mechanism 29, multi-tube action deformation reset mechanism 35, bidirectional step drilling mechanism 48, multi-hole synchronous processing mechanism 66, self-locking fixed processing mechanism 76 and spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com