Auxiliary installation device for train bottom cable box of special-shaped train model of commuter train

A technology for installation assistance and cable boxes, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of dust on the bottom of the car easily falling into the eyes of workers, heavy physical exertion of workers, and low installation efficiency. Achieve the effects of improving work efficiency, stable and safe operation, and high lifting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

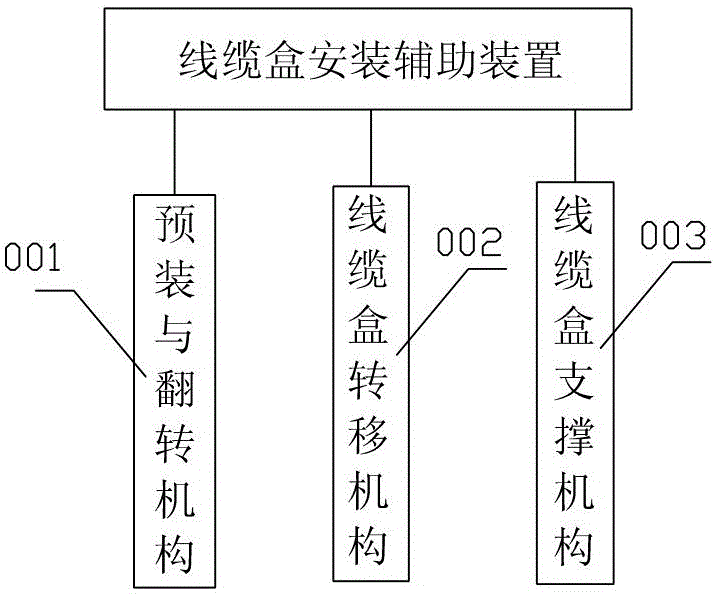

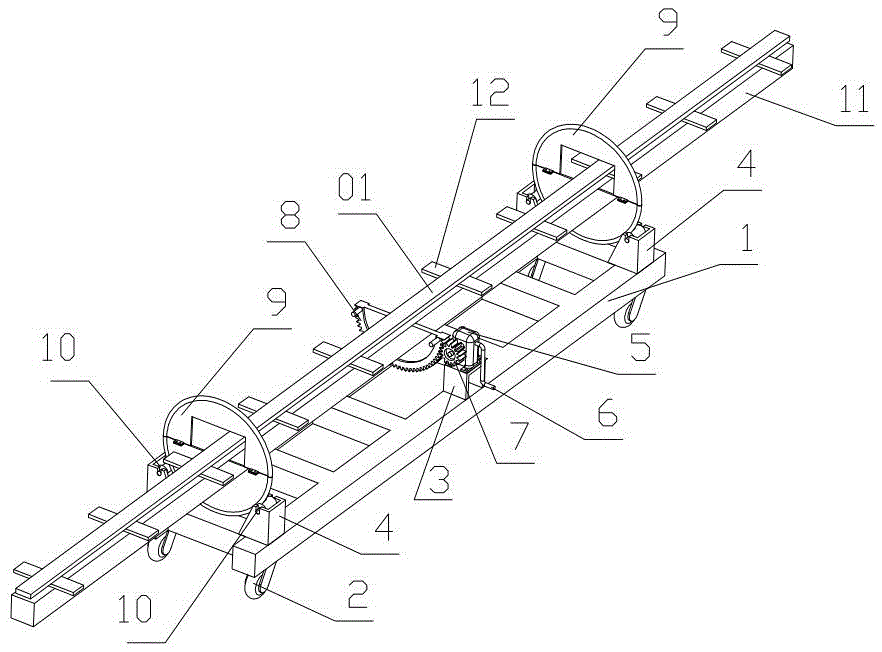

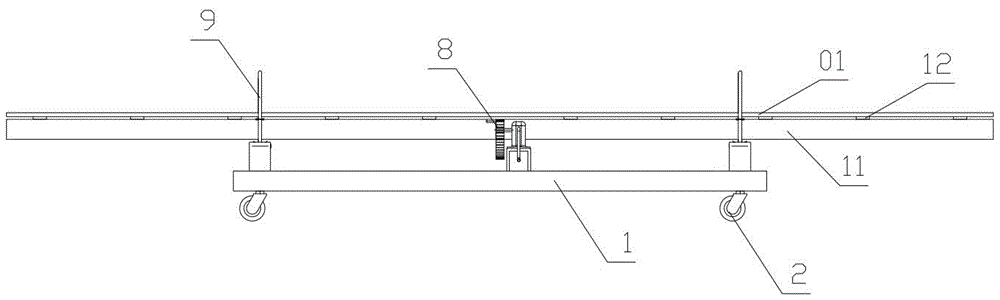

[0031] combined with figure 1 to attach Figure 12 , an auxiliary device for installation of a cable box under a car of different types of urban railway vehicles, which includes a pre-installation and turning mechanism 001, a cable box transfer mechanism 002 and a cable box support mechanism 003; the three are used in sequence;

[0032] The pre-installation and turning mechanism 001 includes a base 1; a plurality of first rollers 2 are installed under the base 1; a turning drive mechanism 3 is installed in the middle of the base 1, and the two ends of the base 1 are respectively installed There is a turning balance mechanism 4; the turning driving mechanism 3 includes a transmission box 5, a handle 6, a first gear 7 and a second gear 8; the transmission box 5 is installed on the base 1, and the handle 6 is installed On the transmission box 5, the power outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com