Device and method for one-way vertical laser cutting cracking groove of automobile connecting rod

A technology of automobile connecting rods and cracking grooves, which is applied in laser welding equipment, components with teeth, cams, etc., can solve the problems affecting the quality and efficiency of products produced by enterprises, the complexity of processing cracking grooves, and the deviation of the depth of cracking grooves on both sides, etc. problems, to improve production quality, simplify cumbersomeness, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

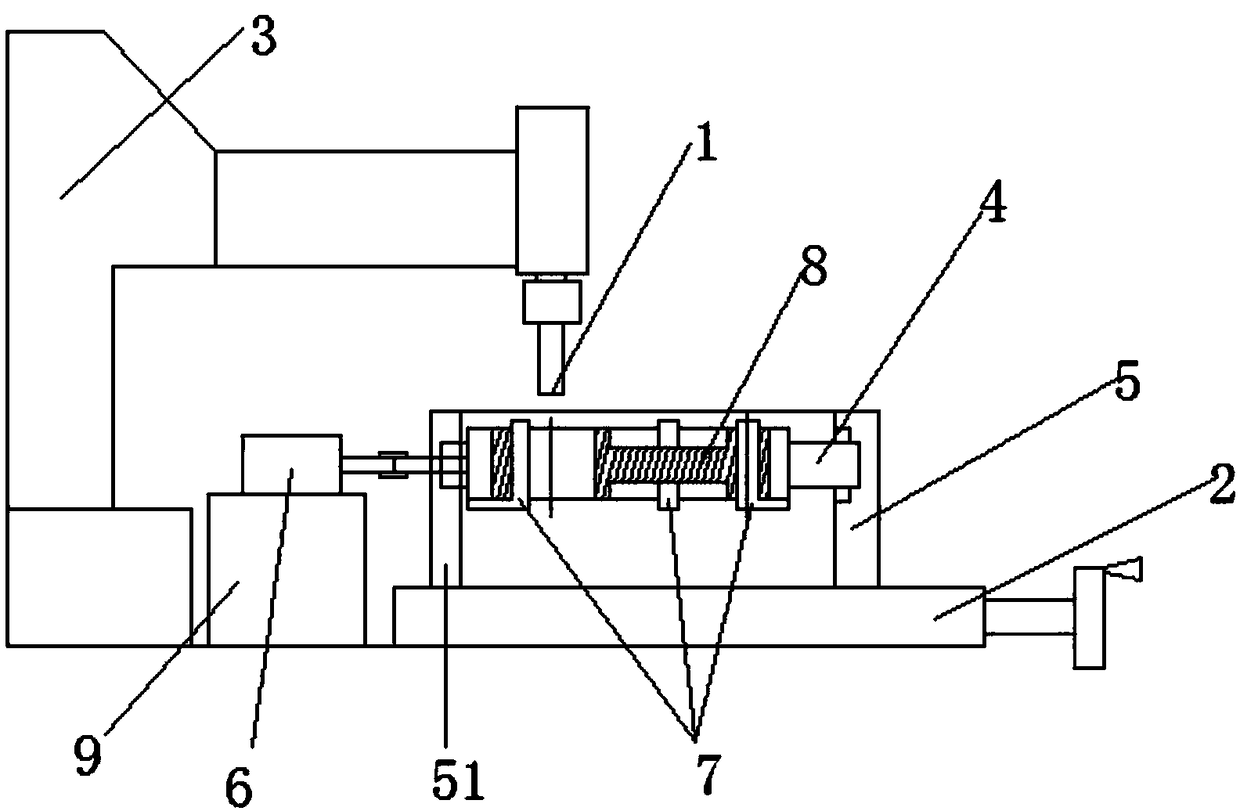

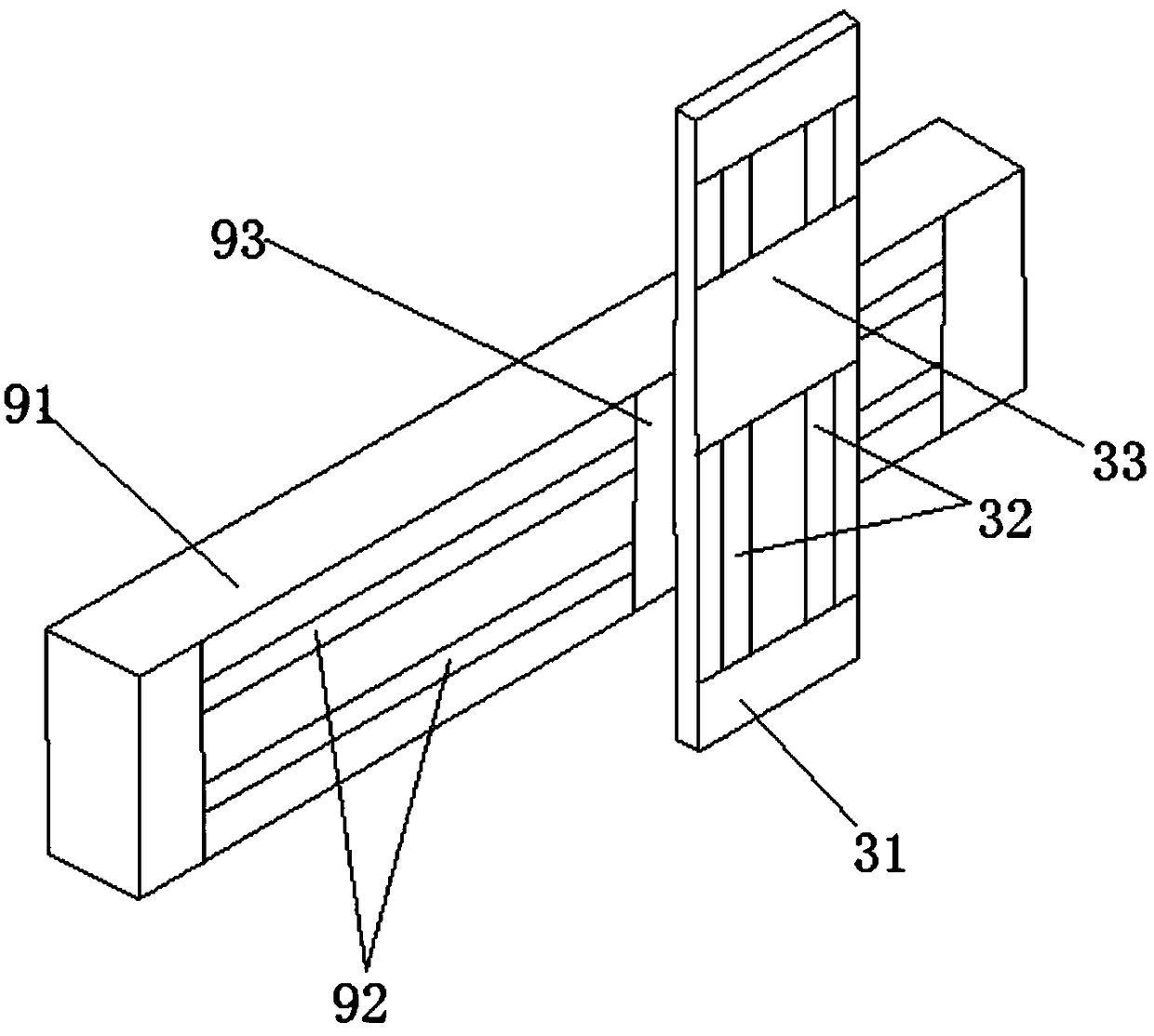

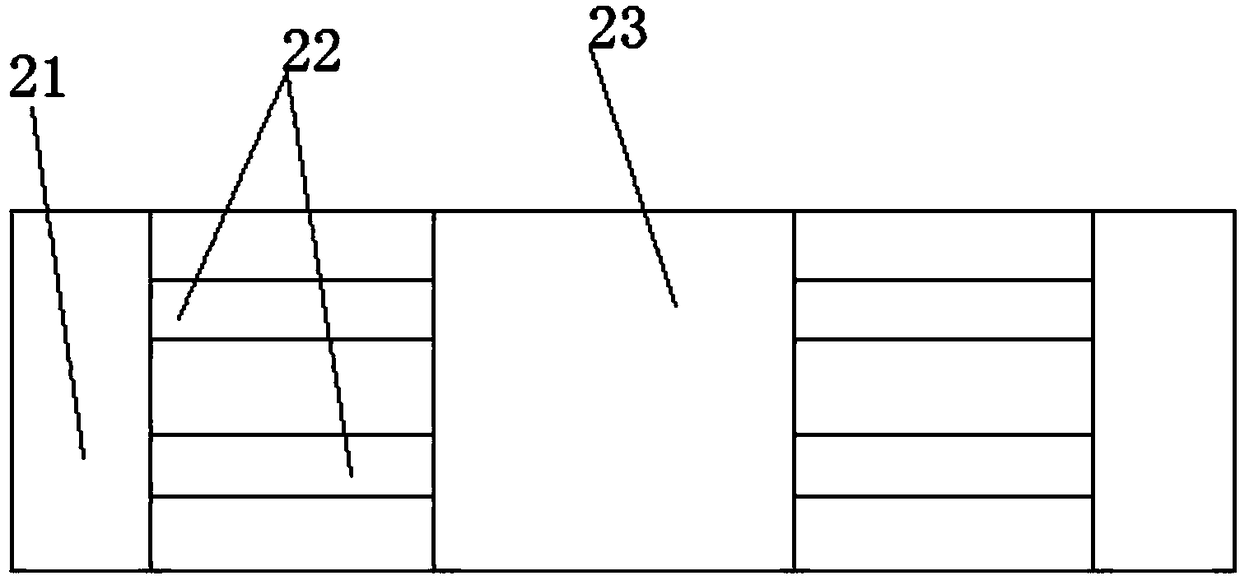

[0031] A schematic diagram of a device for one-way vertical laser cutting of automobile connecting rod cracking grooves in this embodiment is as follows figure 1 As shown, it includes a control unit, a laser cutting head 1, a laser, a worktable, an X-axis mobile platform 2, a Y-axis mobile platform, a Z-axis mobile platform 3, a fixture plate 4, and a clamp body 5, respectively used to drive the X-axis mobile platform. 2. The driving device for the movement of the Y-axis mobile platform and the Z-axis mobile platform 3. The laser and the driving device are connected to the control unit; the laser cutting head 1 is connected to the laser, and the laser is connected to the Z-axis mobile platform 3. The Z-axis The mobile platform 3 is connected with the Y-axis mobile platform; the fixture plate 4 is rotationally connected with the clamp body 5, and the clamp body 5 is fixed on the X-axis mobile platform 2; the X-axis mobile platform 2 and the Y-axis mobile platform are installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com