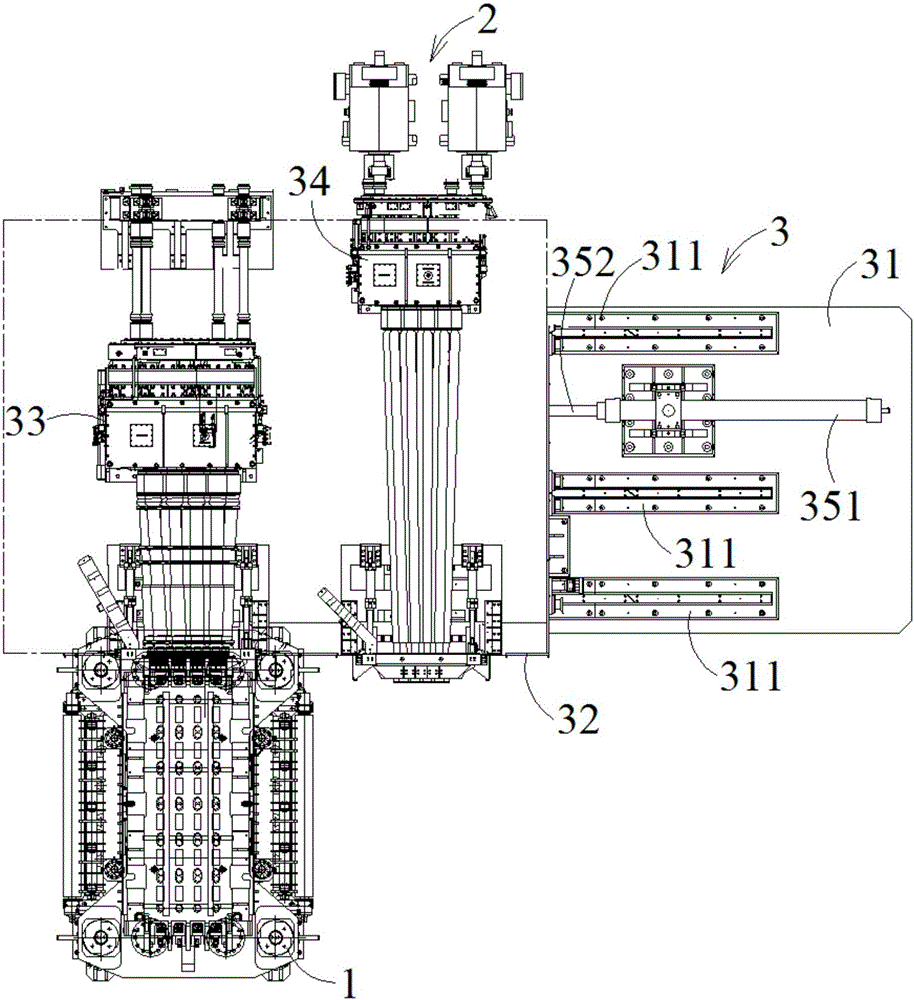

Multi-roll transmission device, cold straightening machine and multi-roll transmission replacement method

A technology of a transmission device and a replacement method, which is applied in the field of metallurgical equipment, can solve the problem of high investment cost, and achieve the effect of improving the utilization rate and saving equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following description of the invention, reference is made to the accompanying drawings, which form a part hereof, and in which are shown by way of illustration different exemplary structures, systems or steps which may implement aspects of the invention. It is to be understood that other specific arrangements of components, structures, exemplary devices, systems and steps may be utilized and structural and functional modifications may be made without departing from the scope of the present invention. Moreover, although the terms "between," "side," and "inside," etc., may be used in this specification to describe various exemplary features and elements of the invention, these terms are used herein for convenience only, for example, according to the appended Orientation of the example described in the figure. Nothing in this specification should be construed as requiring a particular three-dimensional orientation of structures in order to fall within the scope of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com