Sprocket driven drum device, biochemical treatment equipment, system and treatment method

A biochemical treatment and drum technology, applied in chemical instruments and methods, grain treatment, chemical/physical processes, etc., can solve the problems of picking, reducing waste disposal space, and not being able to contact tapered blades, saving time and being easy to operate , the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0032] 1. Biochemical treatment system and biochemical treatment equipment

[0033] The biochemical treatment system is composed of biochemical treatment equipment 100 and control equipment. The biochemical treatment equipment is used to reduce the amount of organic waste, and the control equipment is used to control the biochemical treatment equipment.

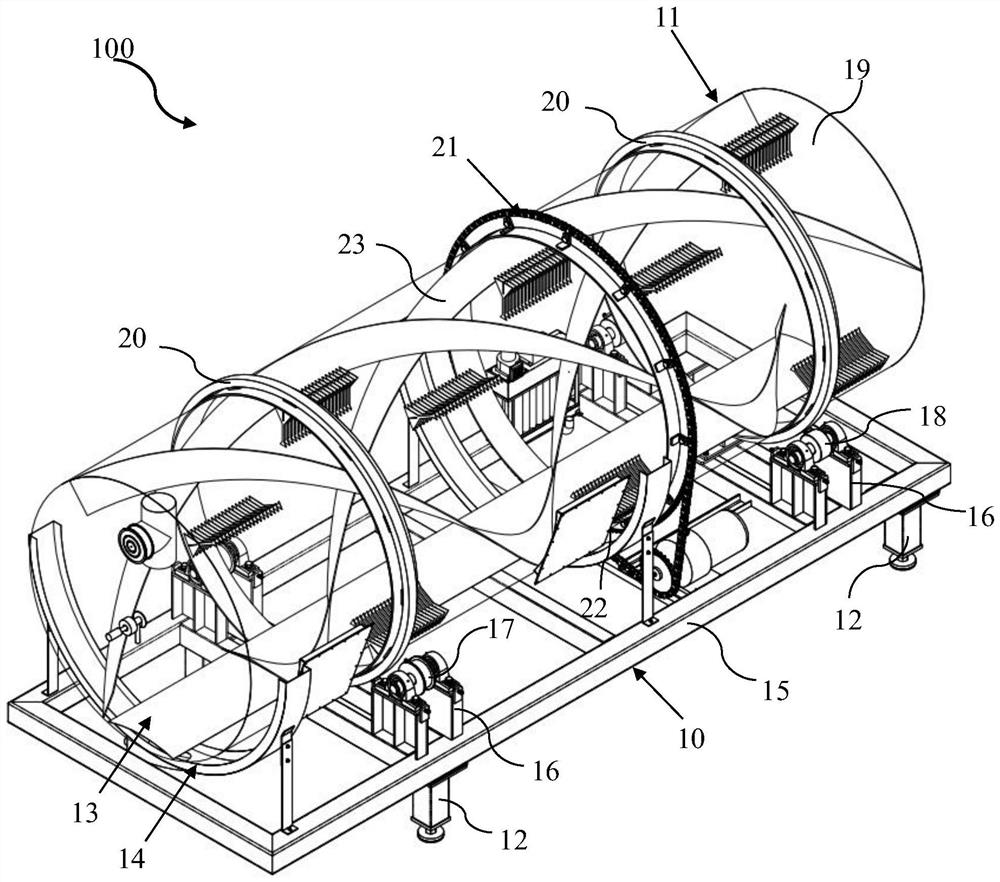

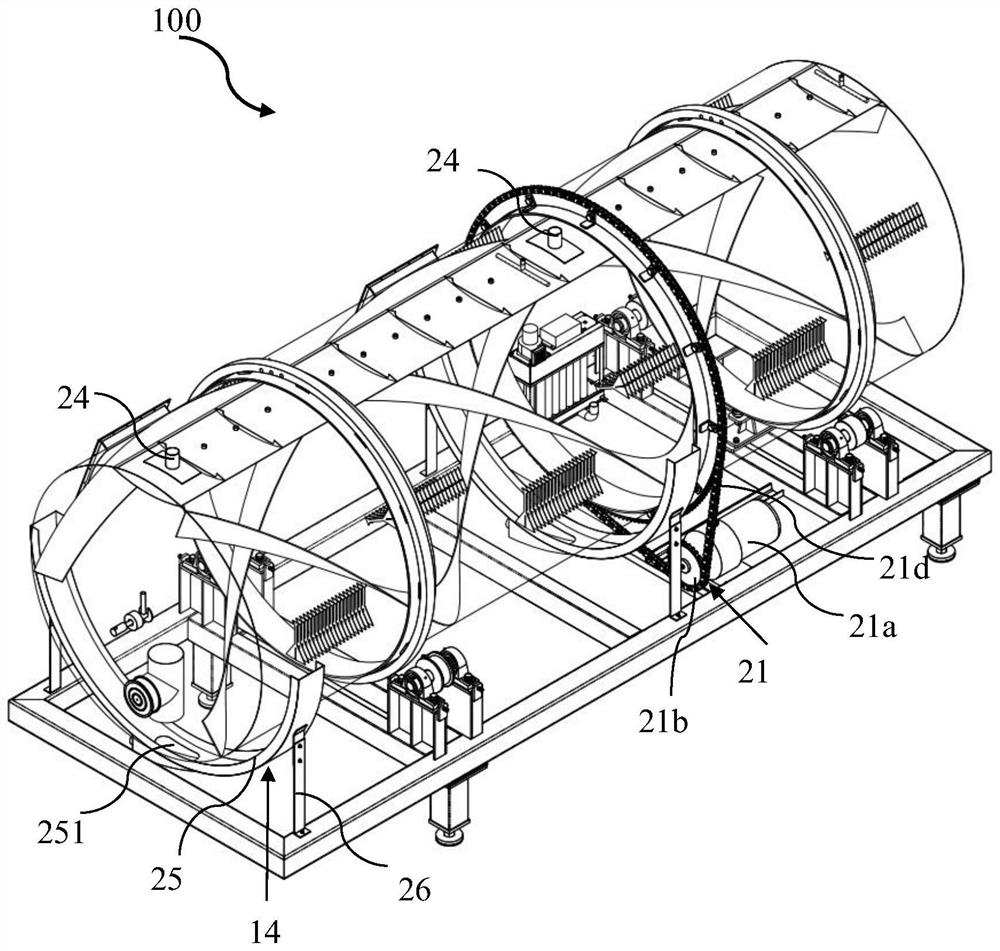

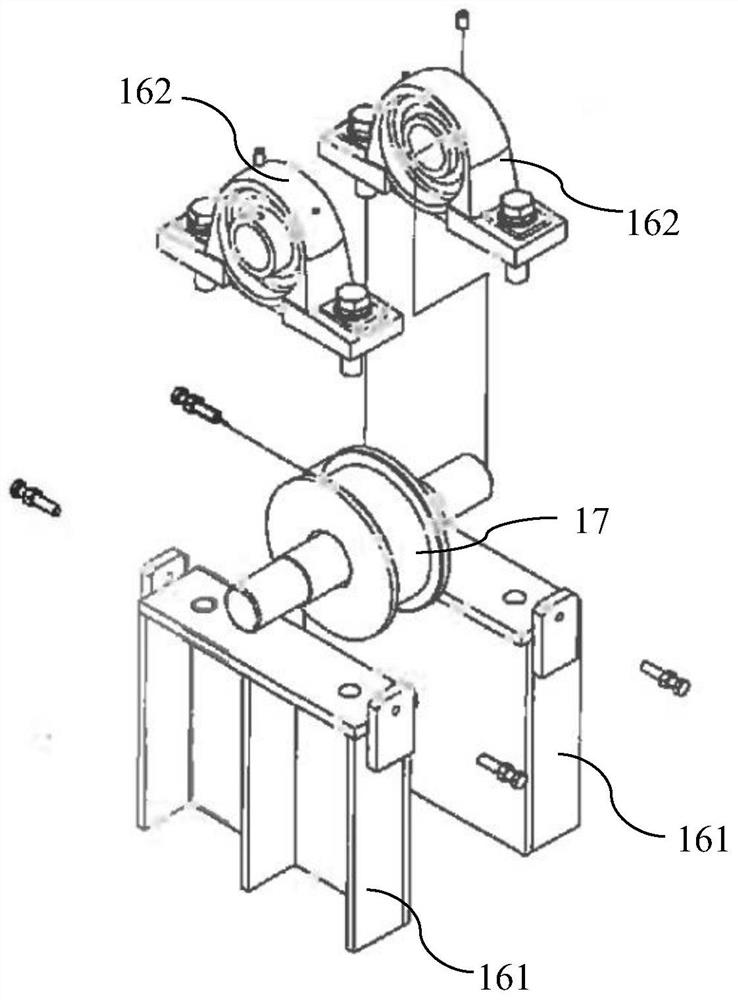

[0034] figure 1 It is a schematic structural diagram of the biochemical treatment equipment in this implementation; figure 2 yes figure 1 Schematic diagram of the structure of the biochemical treatment equipment after the sprocket-driven drum device in the figure rotates 180°.

[0035] Such as figure 1 with figure 2 As shown, the biochemical treatment equipment 100 includes a supporting device 10 , a sprocket driven roller device 11 , a weighing device 12 , a filtering device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com