Garbage biochemical treatment equipment and garbage biochemical treatment system

A technology for biochemical treatment and garbage, applied in grain treatment, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as picking, bacteria death, high operating costs, etc., and achieve the effect of avoiding siltation and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the garbage biochemical treatment equipment and garbage biochemical treatment system of the present invention in conjunction with the accompanying drawings.

[0029] The garbage is transported to the sorting table before the garbage biochemical treatment system of this embodiment, and the inorganic garbage in the garbage is sorted out by staff or instruments to avoid useless treatment.

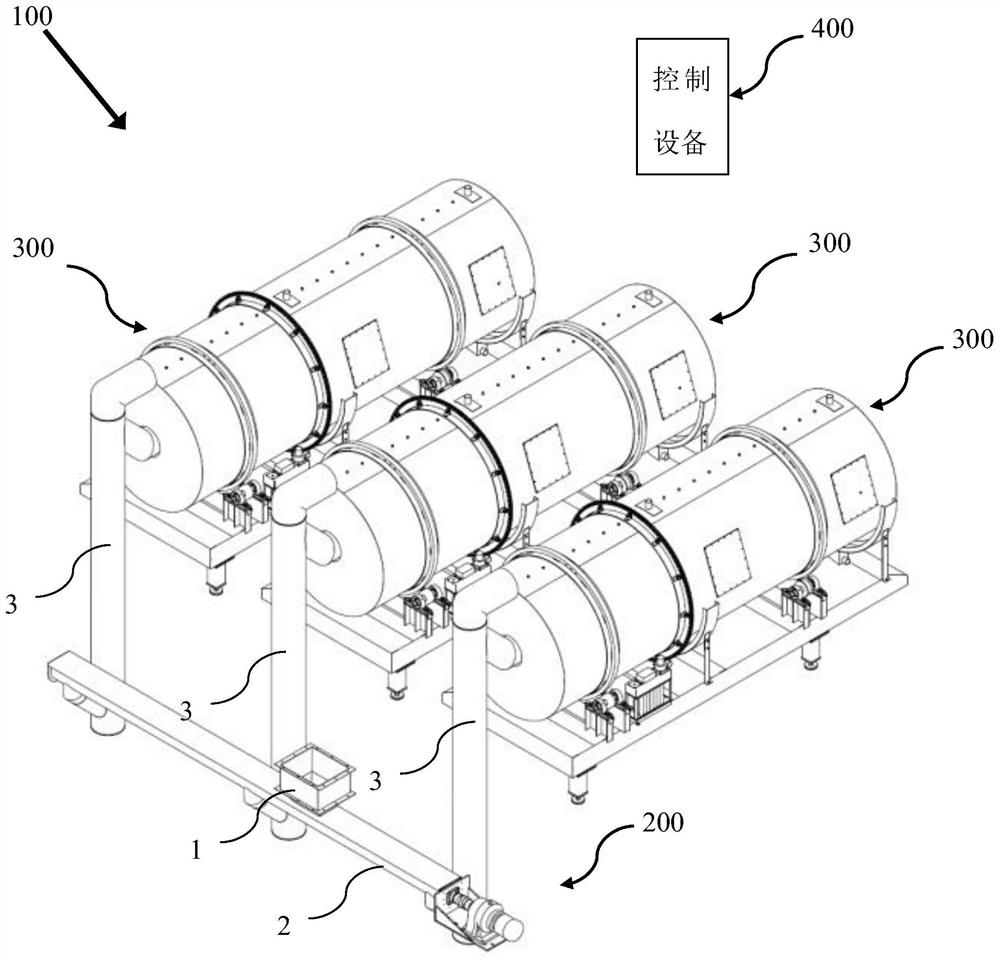

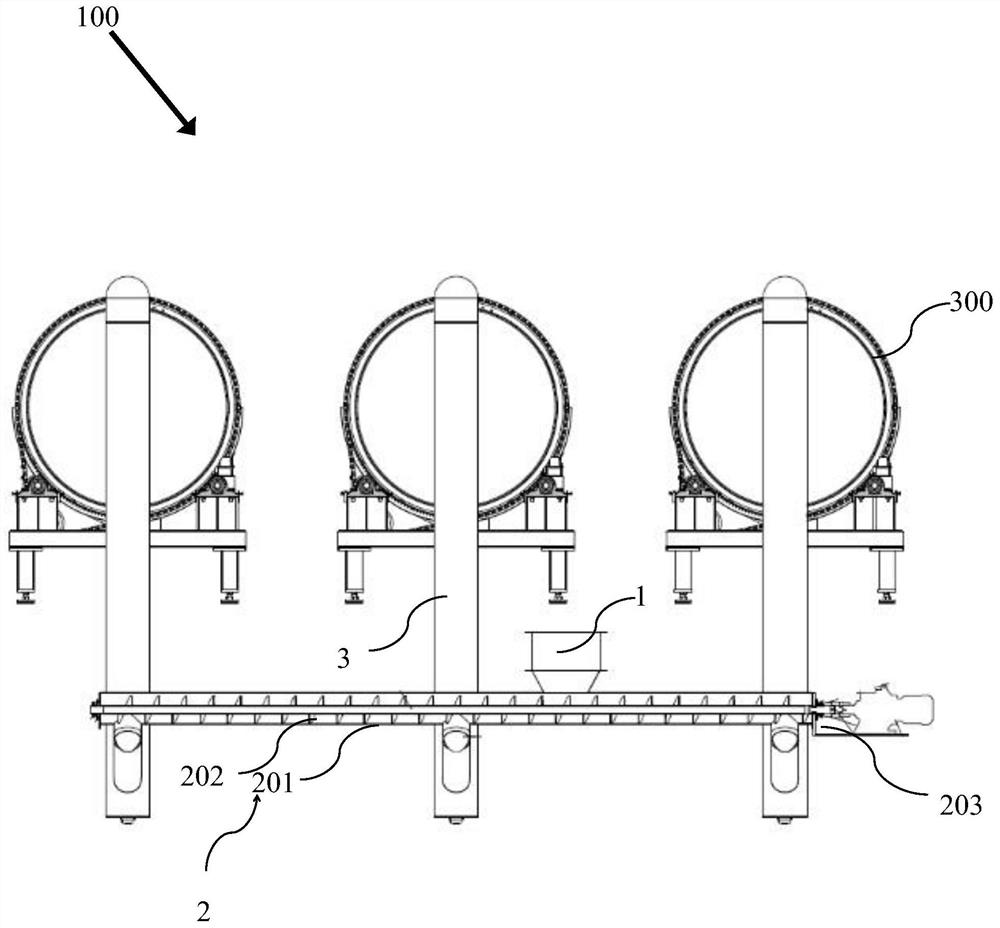

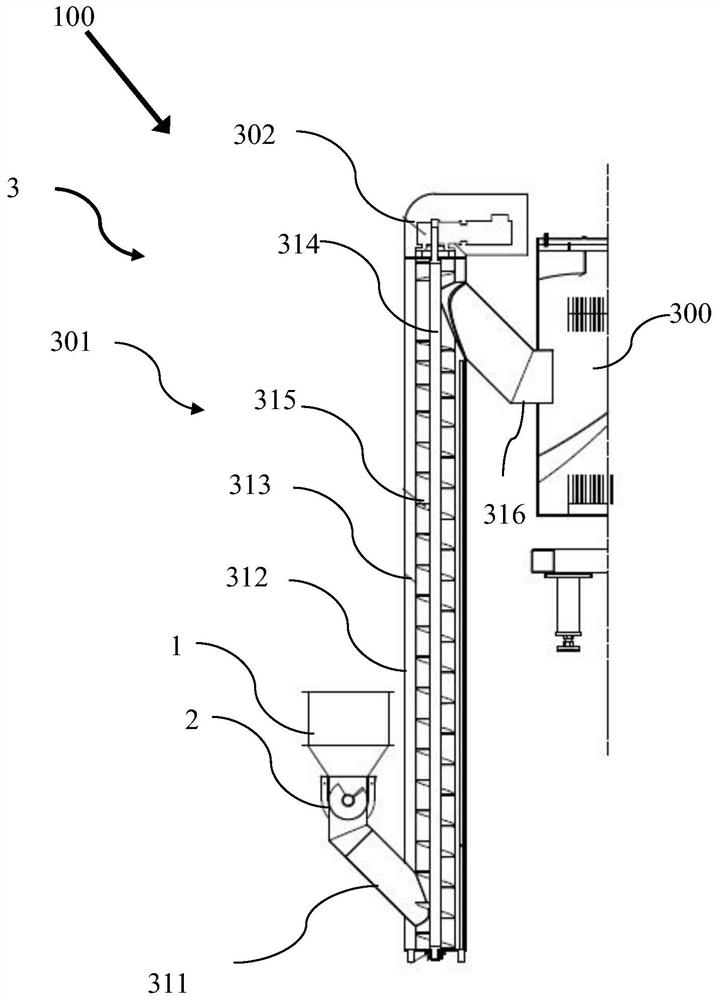

[0030] figure 1 It is a structural schematic diagram of the garbage biochemical treatment system in the embodiment of the present invention.

[0031] The biochemical treatment system 100 is composed of feeding equipment 200 , waste biochemical treatment equipment 300 and control equipment 400 .

[0032] The feeding device 200 is used to transport organic waste. The feeding device 200 includes a crushing mechanis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com