Grid lining plate for ball mill

A ball mill and liner technology, applied in grain processing and other directions, can solve problems such as low work efficiency, inability to disassemble, bolt damage, etc., and achieve the effect of good effect, convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technology of the present invention will be described in detail below in conjunction with the accompanying drawings and specific preferred embodiments, so that the advantages and characteristics of the technology of the present invention can be more easily understood by those skilled in the art. These embodiments are for illustrative purposes only and are not intended to The scope of the present invention is defined.

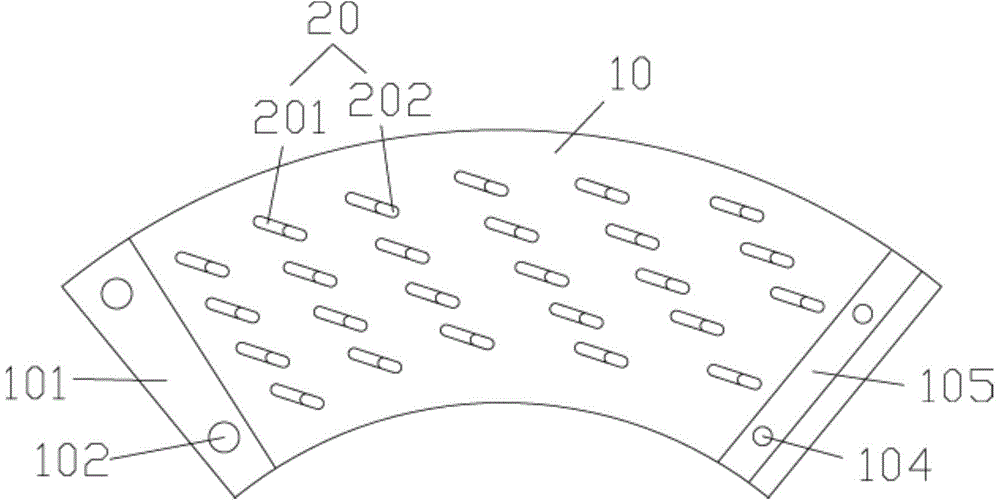

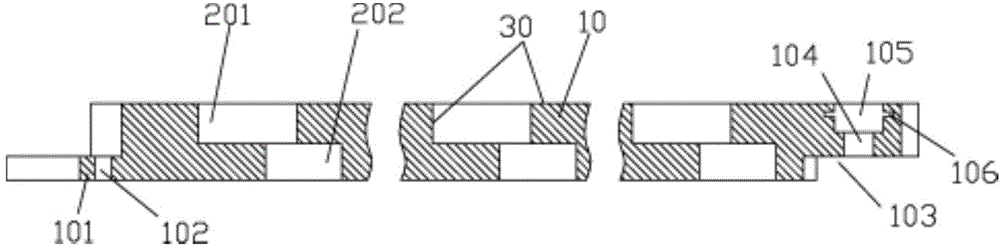

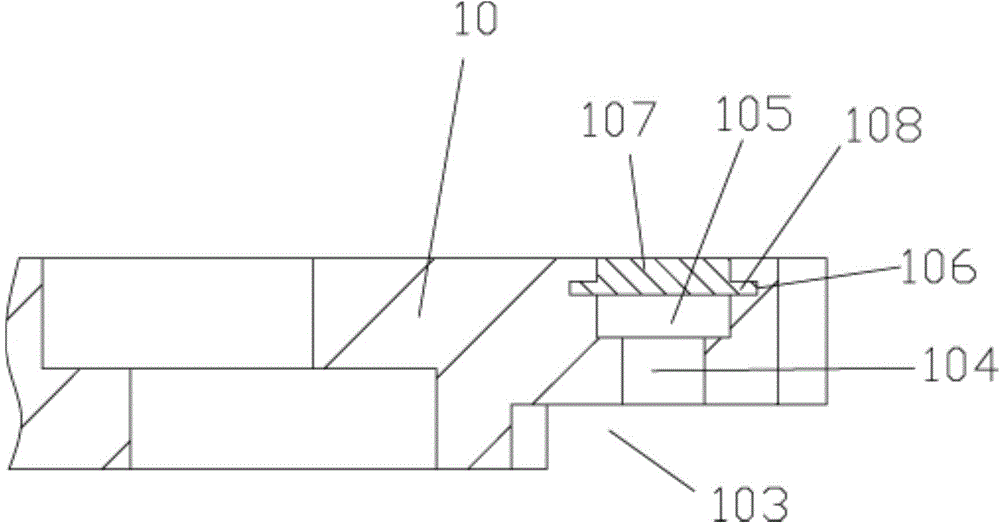

[0024] Examples, see e.g. Figure 1 to Figure 3 As shown, a grid liner for a ball mill includes a liner body 10, the middle of which liner body 10 has a plurality of ore discharge through holes 20, and the lower part of the left side wall of liner body 10 has an outwardly extending connection part 101, the connecting part 101 has a connecting through hole 102, the lower part of the right side wall surface of the liner body 10 has a groove 103 for the connection part 101 of the adjacent liner body 10 to insert, and the top surface of the groove 103 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com