Block-shaped Ag2MoO4@Ag@AgBr ternary complex and preparation method and application thereof

A ternary composite, block-shaped technology, applied in the field of material chemistry, can solve the problems of less research, and achieve the effects of simple preparation method, balanced morphology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

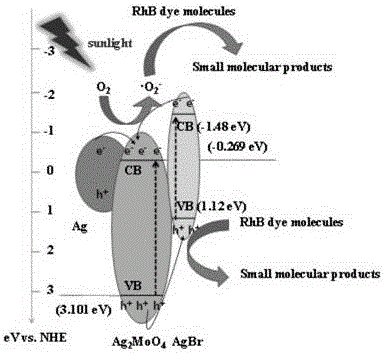

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of Cube Ag 2 MoO 4 @Ag@AgBr ternary complex, the specific steps are as follows:

[0056] 1. In 20mL ethylene glycol, add 2mmol silver nitrate and 1.2g PVP successively to dissolve to obtain a mixed solution of silver nitrate and PVP; in 50mL ethylene glycol, add 1mmol sodium molybdate and stir to dissolve; mix silver nitrate and PVP Add the solution dropwise to the sodium molybdate solution, adjust the pH to about 6.7 with ammonia water, stir it magnetically for 10 minutes, transfer it to a round bottom flask, and react in a constant temperature oil bath at 60°C for 12 hours. The product was washed with distilled water and absolute ethanol for more than 2 times, and dried at a constant temperature of 70°C for 12 hours to obtain the intermediate product square-shaped Ag 2 MoO 4 @Ag.

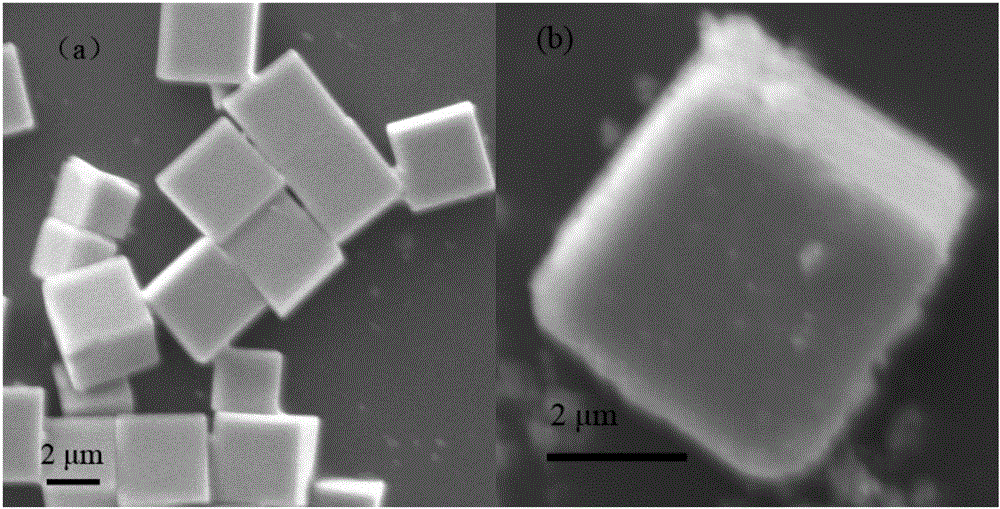

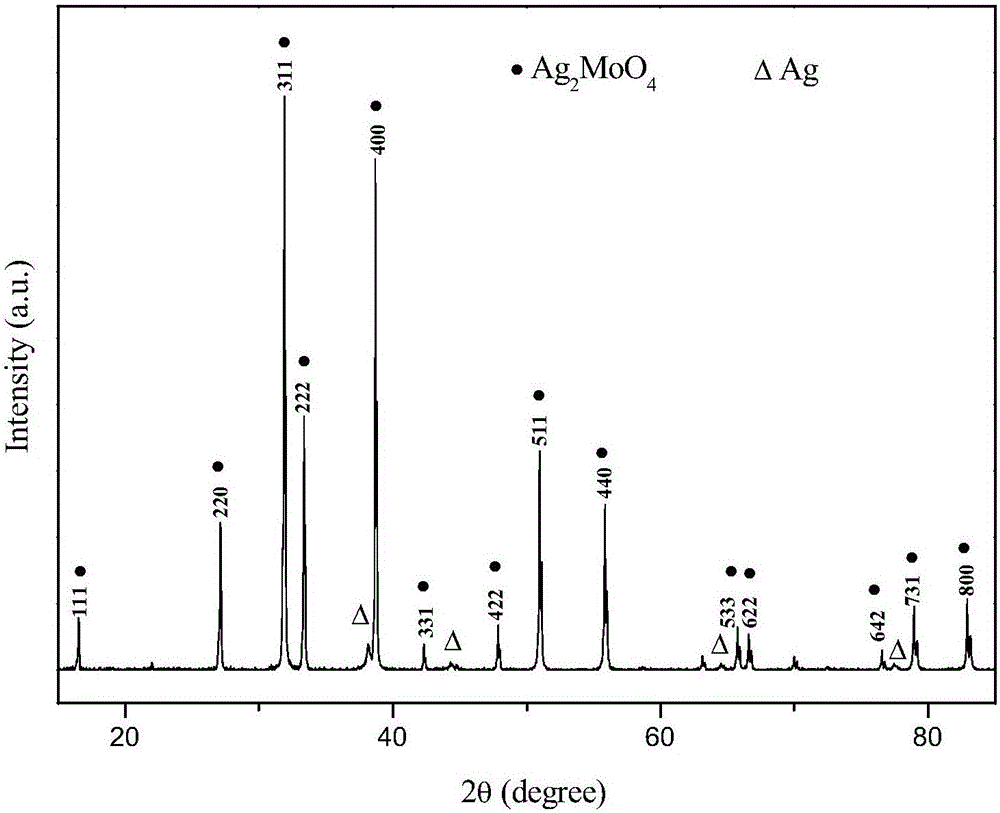

[0057] The resulting intermediate product, square-shaped Ag 2 MoO 4 For scanning electron micrographs of @Ag see figure 1 , X Ray diffraction pattern (XRD) see figure...

Embodiment 2

[0073] Preparation of Cube Ag 2 MoO 4 @Ag@AgBr ternary complex, the specific steps are as follows:

[0074] 1. In 20mL ethylene glycol, add 2mmol silver nitrate and 1.2g PVP in order to dissolve; in 50mL ethylene glycol, add 1mmol sodium molybdate to dissolve with magnetic stirring, and add the mixed solution of silver nitrate and PVP dropwise to the sodium molybdate solution , adjust the pH to about 6 with ammonia water, transfer to a round-bottomed flask after magnetic stirring for 10 minutes, and react for 10 hours in a constant temperature oil bath at 55°C. The product was washed with distilled water and absolute ethanol for more than 2 times, and dried at a constant temperature of 70°C for 12 hours to obtain the intermediate product square-shaped Ag 2 MoO 4 @Ag.

[0075] The resulting intermediate product, square-shaped Ag 2 MoO 4 For scanning electron micrographs of @Ag see Figure 9 , X-ray diffraction pattern (XRD) see Figure 10 .

[0076] 2. Take 0.3757g of ...

Embodiment 3

[0079] Preparation of Cube Ag 2 MoO 4 @Ag@AgBr ternary complex, the specific steps are as follows:

[0080] 1. In 20mL ethylene glycol, add 2mmol silver nitrate and 1.2g PVP in order to dissolve; in 50mL ethylene glycol, add 1mmol sodium molybdate to dissolve with magnetic stirring, and add the mixed solution of silver nitrate and PVP dropwise to the sodium molybdate solution , the pH was adjusted to about 8 with ammonia water, the mixture was stirred by magnetic force for 10 minutes, then transferred to a round bottom flask, and reacted in a constant temperature oil bath at 75°C for 14 hours. The product was washed with distilled water and absolute ethanol for more than 2 times, and dried at a constant temperature of 70°C to obtain a square Ag 2 MoO 4 @Ag.

[0081] The resulting intermediate product, square-shaped Ag 2 MoO 4 For scanning electron micrographs of @Ag see Figure 13 , X Ray diffraction pattern (XRD) see Figure 14 .

[0082] 2. Take 0.3757g of the inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com