Anti-hydrothermal aging and sulfur-resistant irpdpt/irpd catalyst and its preparation method and application

A catalyst, hydrothermal resistance technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of shortened service life, limited catalyst durability, and reduced catalyst Active and other issues, to achieve good sulfur resistance, high durability, good hydrothermal aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) 10g ZrO 2 Add 6.3mL H to the powder 2 IrCl 6 solution, the H 2 IrCl 6 The solution contains 0.05g of Ir, stirred for 30 minutes to form a meat floss-like wet powder, left to stand for 2 hours, dried at 80°C for 2 hours, then dried at 120°C for 2 hours, and the dried powder was placed in a muffle furnace and roasted at 500°C for 8 hours. Get 0.5% Ir / ZrO 2 catalyst powder;

[0028] (2) 0.5% Ir / ZrO obtained in step (1) 2 Add 6.3mL Pd(NO 3 ) 2 with Pt(NO 3 ) 4 In the mixed solution, the mixed solution contains 0.15g of Pd and 0.03g of Pt, stirred for 30min to form a wet powder like meat floss, left for 2h, dried at 60°C for 5h, then dried at 105°C for 3h, and the dried powder Put it in a muffle furnace and bake at 550°C for 3h to get 0.5%Ir-1.5%Pd-0.3%Pt / ZrO 2 Catalyst powder, the catalyst powder is the IrPdPt catalyst.

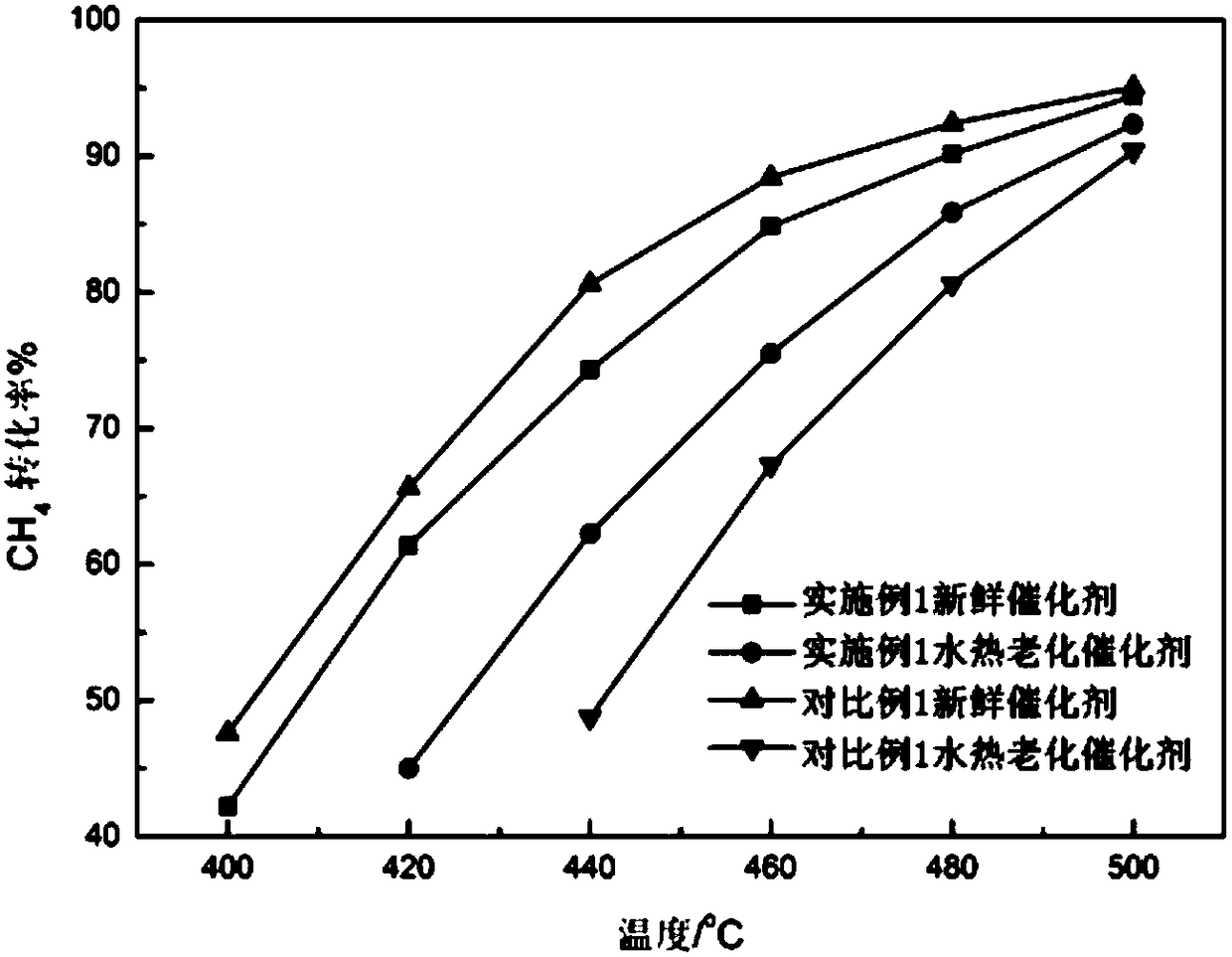

[0029] The resulting powdered IrPdPt catalyst was fabricated into a monolithic catalyst, and the monolithic fresh and hydrothermally aged ...

Embodiment 2

[0038] (1) 10g 15% ZrO 2 -85% Al 2 o 3 Add 13mL H to the powder 2 IrCl 6 solution, the H 2 IrCl 6 The solution contains 0.03g of Ir, stirred for 30 minutes to form a meat floss-like wet powder, allowed to stand for 3 hours, dried at 80°C for 3 hours, then dried at 120°C for 3 hours, and the dried powder was placed in a muffle furnace and roasted at 500°C for 6 hours. Get 0.3%Ir / 15%ZrO 2 -85% Al 2 o 3 catalyst powder;

[0039] (2) 0.3%Ir / 15%ZrO obtained in step (1) 2 -85% Al 2 o 3 Add 13mL Pd(NO 3 ) 2 In solution, the Pd(NO 3 ) 2 The solution contains 0.15g of Pd, stirred for 30min to form a meat floss-like wet powder, left to stand for 2h, dried at 80°C for 3h, then dried at 120°C for 3h, the dried powder was placed in a muffle furnace and roasted at 600°C for 3h, Get 0.3%Ir-1.5%Pd / 15%ZrO 2 -85% Al 2 o 3 Catalyst powder, the catalyst powder is the IrPd catalyst.

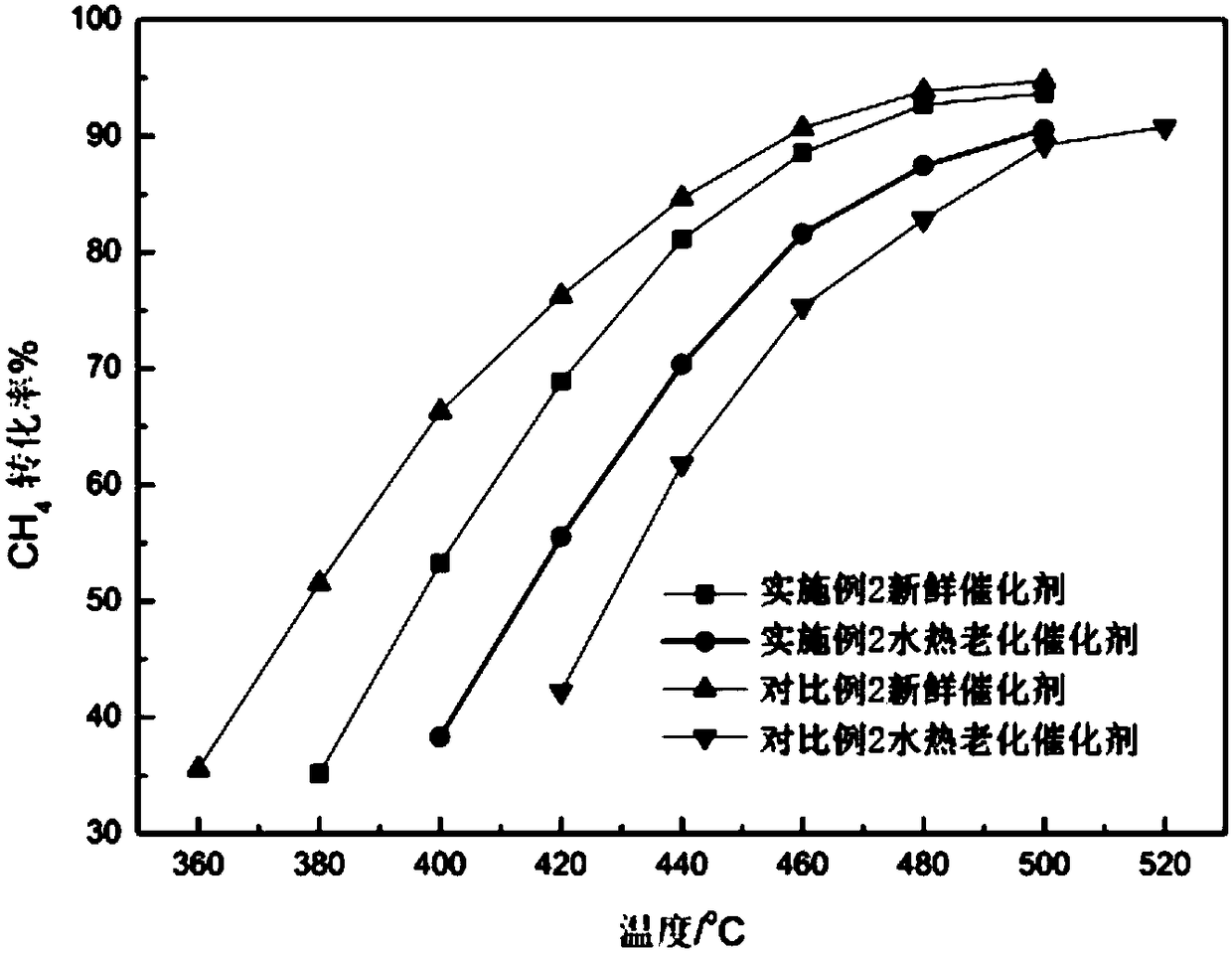

[0040] The resulting IrPd catalyst was fabricated into a monolithic catalyst, and the monolith...

Embodiment 3

[0049] (1) 10g Al 2 o 3 Add 13mL H to the powder 2 IrCl 6 solution, the H 2 IrCl 6 The solution contains 0.01g Ir, stirred for 30 minutes to form a meat floss-like wet powder, left to stand for 2 hours, dried at 80°C for 5 hours, then dried at 120°C for 3 hours, and the dried powder was placed in a muffle furnace and roasted at 600°C for 3 hours to obtain 0.1%Ir / Al 2 o 3 catalyst powder;

[0050] (2) 0.1% Ir / Al obtained from step (1) 2 o 3 Add 13mL of Pd(NO 3 ) 2 with Pt(NO 3 ) 4 In the mixed solution containing 0.15g Pd and 0.03g Pt, the mixed solution was stirred for 30 minutes to form a meat floss-like wet powder, left to stand for 2 hours, dried at 80°C for 5 hours, and then dried at 120°C for 3 hours, and the dried powder was placed Calcined at 500°C for 8 hours in a muffle furnace to obtain 0.1%Ir-1.5%Pd-0.3%Pt / Al 2 o 3 Catalyst powder, the catalyst powder is the IrPdPt catalyst.

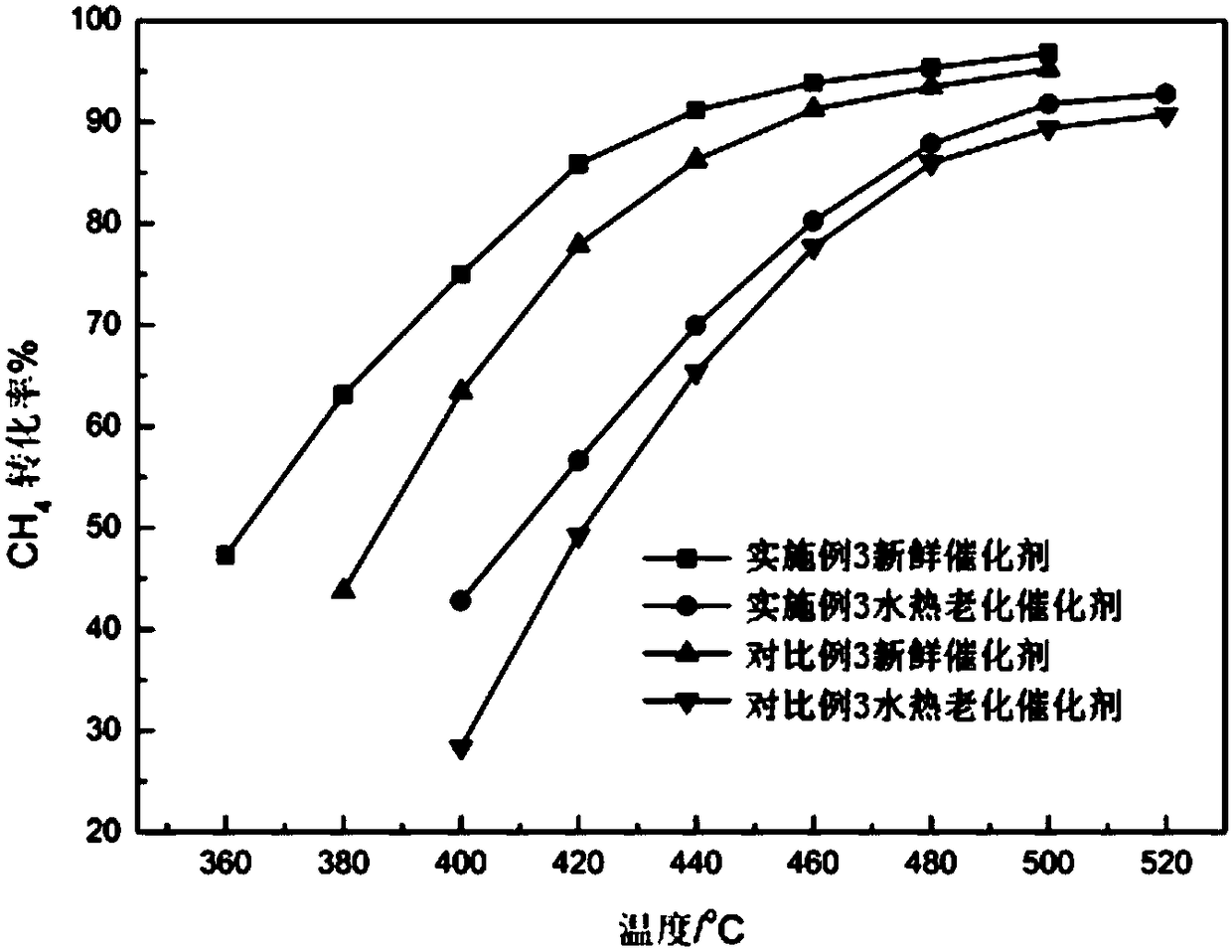

[0051] The resulting IrPdPt catalyst was fabricated into a monolithic cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com