Welding method and welding structure of metal members

A technology for metal parts and welding methods, which is applied in welding/welding/cutting objects, welding equipment, metal processing, etc., can solve the problems of inability to suppress pores and pits in the welded part, and no enlightenment, and achieves suppression of pores and pitting. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

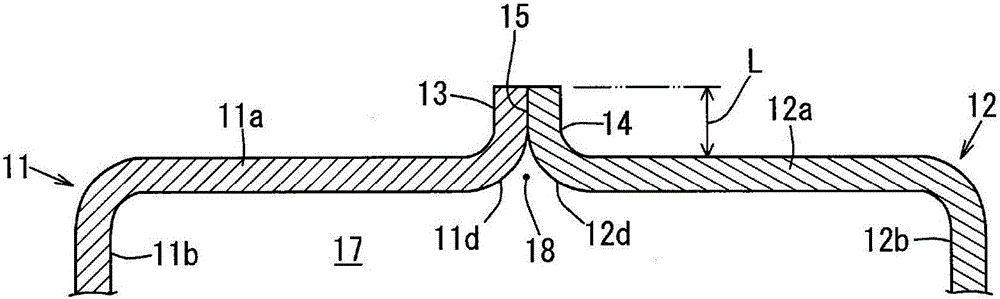

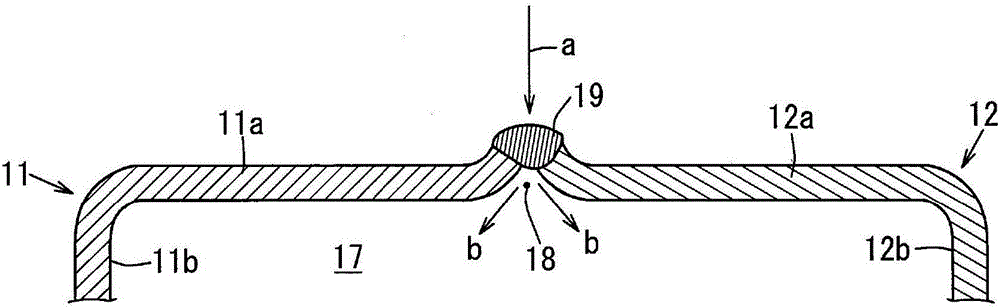

[0038]In order to prevent the zinc vapor generated during arc welding from remaining in the molten metal between the core wire and the base material (steel plate), thereby suppressing the generation of pores and pits in the welded part, the first metal part made of galvanized steel plate and the In the welding method of metal parts in which the second metal part made of galvanized steel sheet adjacent to the first metal part is arc-welded, the welding method includes: a first step of connecting the first and second metal parts to the adjacent part respectively. bending in the same direction to form the flange overlapping portion where the flange portions are in contact with each other; the second step is to perform arc welding from the end of the above-mentioned flange overlapping portion; and the third step is to perform welding until the arc welding occurs. The molten metal of the core wire and the base material reaches at least the surface on the opposite side of the overlap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com