Transparent-type vitamin E acetate dry powder and preparation method thereof

A technology of acetate and vitamin, which is applied in the field of preparation of transparent vitamin E acetate dry powder, can solve problems such as turbidity not meeting the requirements, and achieve the effect of more uniform emulsion, convenient transportation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

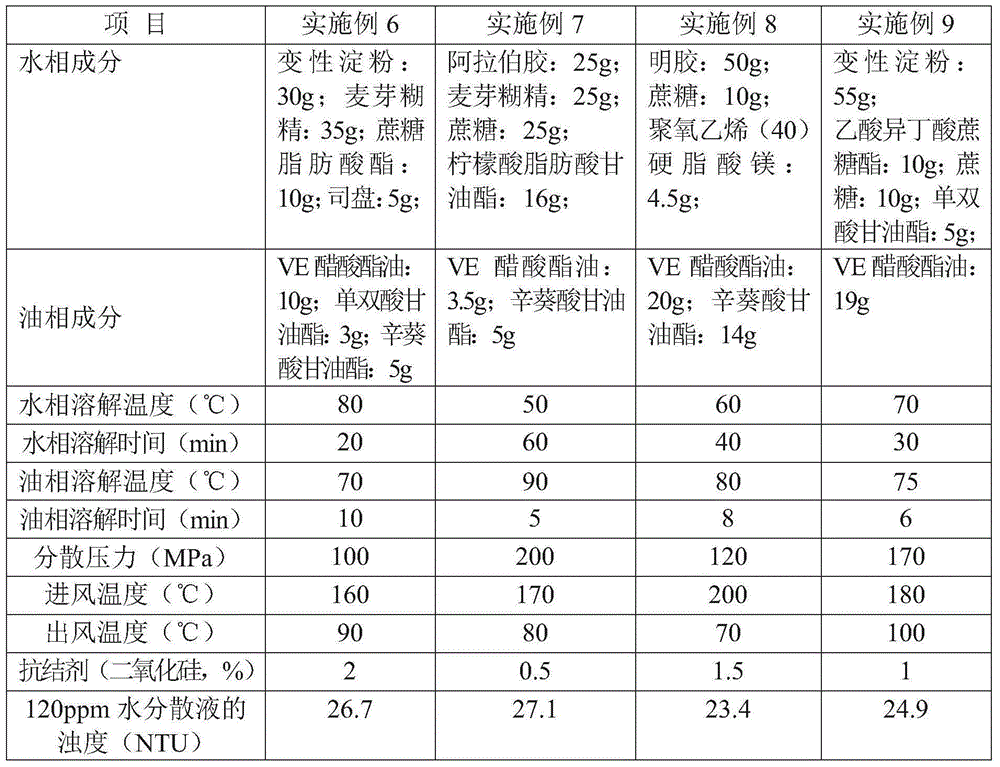

Examples

Embodiment 1

[0025] Aqueous phase preparation: weigh 40g of gum arabic, 19.5g of sucrose, and 20g of Tween, add 150ml of water, dissolve at 70°C for 40 minutes, and prepare an aqueous phase solution;

[0026] Oil phase preparation: Weigh 10g of vitamin E acetate oil, 10g of caprylic acid glyceride, and dissolve at 85°C for 6 minutes;

[0027] Emulsifying the prepared aqueous phase solution and oil phase solution to obtain a uniformly dispersed emulsion;

[0028] Dispersion conditions are as follows: use ultra-high pressure micro-fluidic nano-dispersion instrument M-110S produced by MFIC Company of the United States to conduct nano-dispersion under the condition of a pressure of 100 MPa;

[0029] Spray drying: the air inlet temperature of the spray drying is 180° C., and the air outlet temperature is 75° C., and the transparent vitamin E acetate dry powder is obtained by spray drying, and 0.5% magnesium stearate of the dry powder weight is added.

[0030] Weigh 30mg of vitamin E acetate dr...

Embodiment 2

[0032] Water phase preparation: Weigh 45g of modified starch, 17g of maltodextrin, and 12g of Tween, add 100ml of water, dissolve at 75°C for 50 minutes, and prepare an aqueous phase solution;

[0033] Preparation of the oil phase: weigh 15g of vitamin E acetate oil, 9g of caprylic glycerin, and dissolve at 80°C for 8 minutes;

[0034] Emulsifying the prepared aqueous phase solution and oil phase solution to obtain a uniformly dispersed emulsion;

[0035] Dispersion conditions are as follows: use the ultra-high pressure micro-fluidic nano-dispersion instrument M-110S produced by the American MFIC company to conduct nano-dispersion under the condition of a pressure of 150MPa;

[0036] Spray drying: the air inlet temperature of the spray drying is 180° C., and the air outlet temperature is 80° C., and the transparent vitamin E acetate dry powder is obtained by spray drying, and 2% magnesium stearate of the dry powder weight is added.

[0037] Weigh 20.0 mg vitamin E acetate dry...

Embodiment 3

[0039] Water phase preparation: Weigh 20g of gelatin, 44g of sucrose, and 12g of Span, add 200ml of water, and dissolve at 70°C for 60 minutes to prepare an aqueous phase solution;

[0040] Oil phase preparation: weigh 18g of vitamin E acetate oil, 5g of monoglyceride and diglyceride, and dissolve at 80°C for 10 minutes;

[0041] Emulsifying the prepared aqueous phase solution and oil phase solution to obtain a uniformly dispersed emulsion;

[0042] Dispersion conditions are as follows: use the ultra-high pressure micro-fluidic nano-disperser M-110S produced by the American MFIC company to conduct nano-dispersion under the condition of a pressure of 135MPa;

[0043] Spray drying: the air inlet temperature of the spray drying is 185°C, and the air outlet temperature is 75°C, and the transparent vitamin E acetate dry powder is obtained by spray drying, and 1% magnesium stearate by weight of the dry powder is added.

[0044] Weigh 16.67mg vitamin E acetate dry powder into a 25mL v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Turbidity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

| Turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com