Inductance coil automatic dispensing assembly equipment and method thereof

A technology of automatic dispensing and inductance coil, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc. Unable to guarantee the consistency of product quality and other problems, to achieve the effect of ensuring safety and stability, improving processing efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

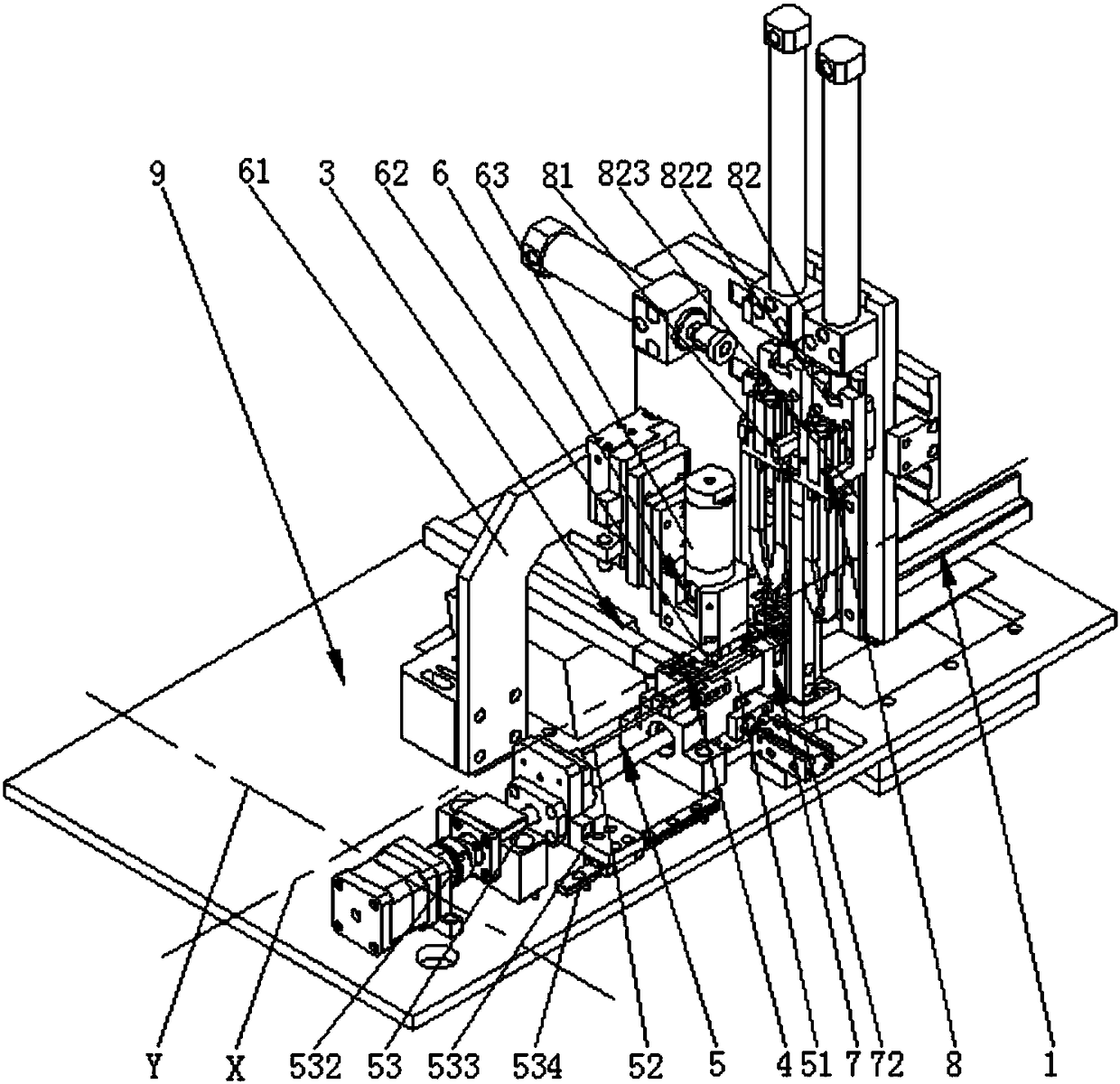

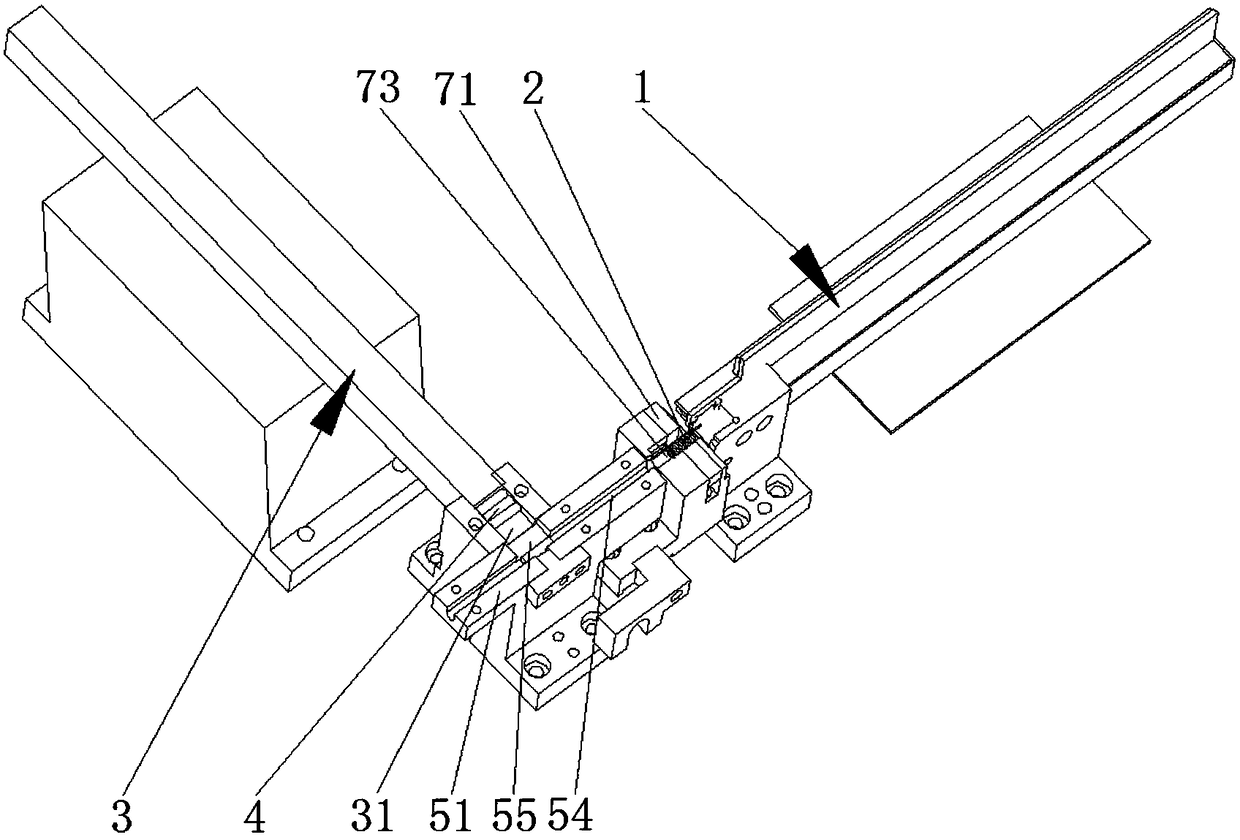

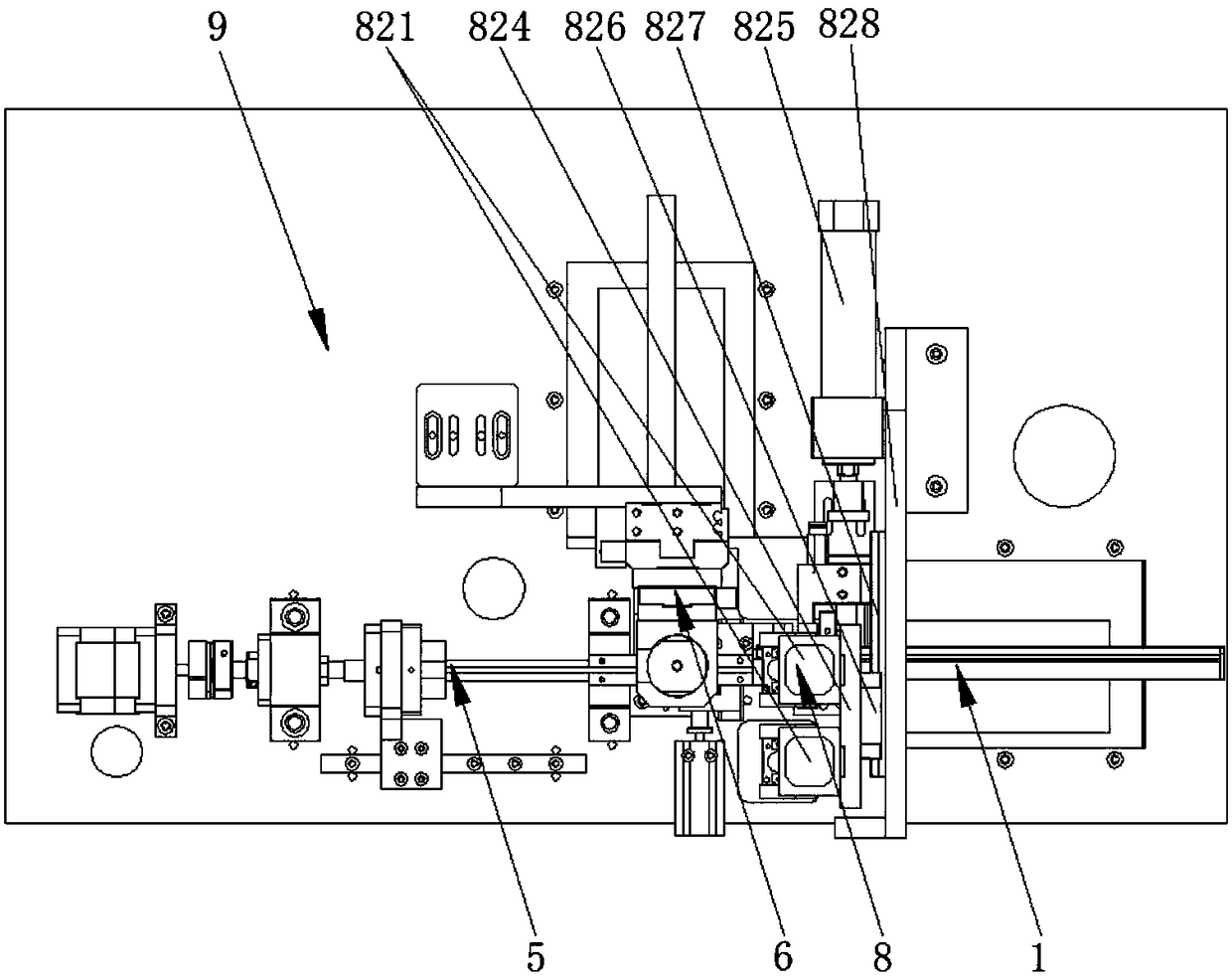

[0035] The inductance coil automatic dispensing and assembling equipment disclosed by the present invention, as attached figure 1 As shown, it includes a supporting platform 9, on which there are a coil conveying line 1, a magnetic core conveying line 3, a magnetic core pushing mechanism 5, a dispensing mechanism 6 and a dislocation mechanism 7.

[0036] The coil delivery line 1 is used to deliver the spring-like coil 2, the magnetic core delivery line 3 is used to provide a cylindrical magnetic core 4, the magnetic core delivery line 3 is arranged p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com