Downwards inclined light bar provided with bent-pin circuit connectors and display screen

A technology of circuit connectors and light strips, which is applied in the direction of instruments, identification devices, etc., can solve the problems of LED light tilting, installation difficulties, maintenance and replacement of faulty light strips, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

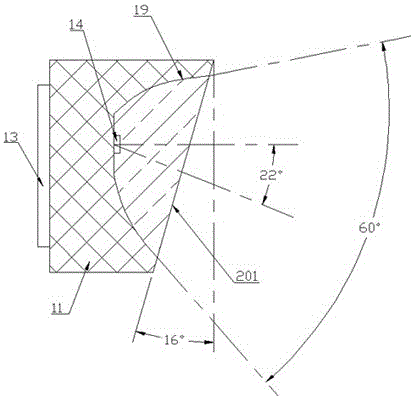

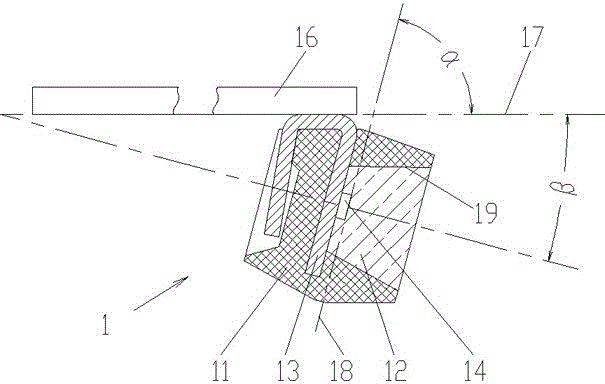

[0035] Embodiment 1 is a light bar that uses bent-leg circuit connectors to tilt down. Figure 7 It is the structural representation of embodiment 1. See Figure 7 A plurality of light-emitting elements 1 are vertically inserted and welded on the light bar PCB 2, and a bent circuit connector 3 is installed, the pin 6 of which is inserted into the light bar PCB 2 for welding connection. The light bar PCB 2 is also equipped with a drive control circuit. One end of the circuit connector 3 is connected to the light bar PCB 2 , and the other end is connected to the column PCB 10 . All the pins at one end of the circuit connector 3 are properly bent at an angle so that there is an angle α between the extension surface of the light bar PCB plane 4 and the extension surface of the column PCB plane 5, and α can be greater than 0° and less than 90° Choose from a range. In this way, when the column PCB 10 is vertically installed on the ground, the light emitting element 1 on the ligh...

Embodiment 2

[0044] Embodiment 2 is another light bar that uses a bent-pin circuit connector to tilt down. Figure 12 It is the structural representation of embodiment 2. See Figure 12 A plurality of light-emitting elements 1 are vertically inserted and welded on the light bar PCB 2 , and the welded light-emitting elements 1 are bent at 90° at the edge of the light bar PCB 2 at the same time using a tooling mold. The light bar PCB 2 is also equipped with a bent-pin circuit connector 3, and the two rows of pins 6 of the circuit connector 3 are pins, which straddle the front and back sides of the light bar PCB 2 for soldering connection, so that the light bar can be made Narrower, improve the air permeability of the light bar screen. The light bar PCB 2 is also equipped with a drive control circuit. One end of the circuit connector 3 is connected to the light bar PCB 2 , and the other end is connected to the column PCB 10 . All the pins at one end of the circuit connector 3 are properly...

Embodiment 3

[0052] Embodiment 3 is a light bar display screen that uses a bent-pin circuit connector to tilt down. Figure 14 It is the structural representation of embodiment 3. See Figure 14 , The light bar display is assembled by one or more light bars that use bent-pin circuit connectors to tilt down. A power supply 12 and a column PCB 10 are installed in the column 11 , and a circuit is installed on the column PCB 10 .

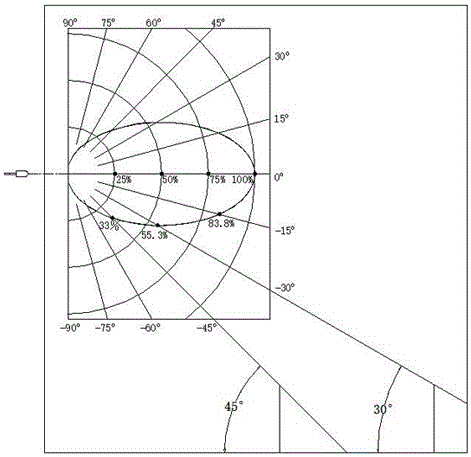

[0053] Apparently, the downward tilting light bar using the bent-leg circuit connector implemented in the present invention realizes the downward tilting of the maximum light intensity angle of the LED element, which improves the perceived brightness of the display screen composed of it and is installed at a high place, thereby improving the brightness of the display screen. energy-saving effect. For example, see figure 1 , assuming that the light distribution curves of LED lamps in Embodiments 1, 2 and 3 are similar figure 1 , and set the maximum light intensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com