Dynamic optimization control method of process quality control graph and age-set maintenance combined design

A process quality and control method technology, applied in the direction of program control, electrical program control, comprehensive factory control, etc., to achieve the effect of solving continuous optimization problems and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following takes a test production system as an example to further describe the implementation of the present invention in detail.

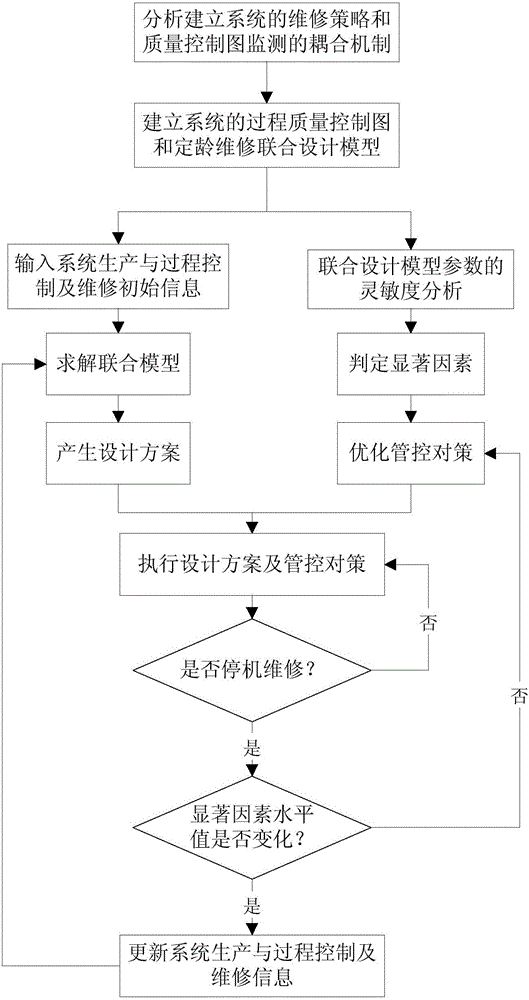

[0038] The dynamic process quality control chart and the control method of the fixed age maintenance joint design plan, such as figure 1 , 2 , 3, 4, and 5, the specific steps of the method are as follows:

[0039] Step 1: Analyze the system to establish a coupling mechanism of maintenance strategy and control chart monitoring;

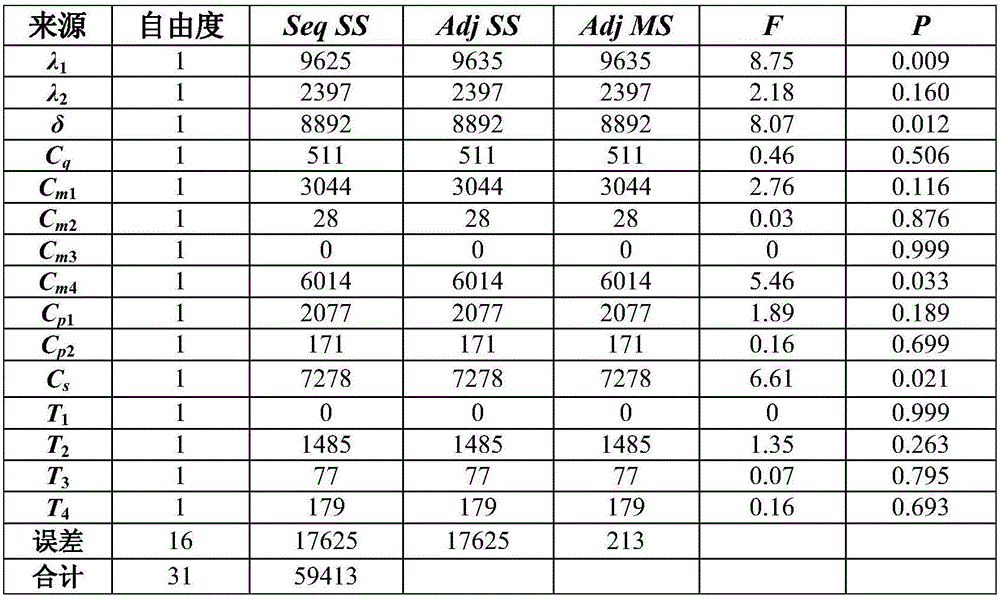

[0040] Suppose the system has three possible states: controlled, out of control, and faulty. It is known that during each maintenance interval, the time points t when the system turns from controlled to out of control and from out of control to downtime respectively obey the parameter λ 1 And λ 2 Exponential distribution, the density function is f 1 (u) and f 2 (v); The process quality characteristic of the system output is X, when controlled, X~N(μ,σ 2 ), X~N(μ+δ,σ 2 );use The control chart monitors the process quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com