Device and method for studying migration law of temporary plugging agent in horizontal well or vertical well temporary plugging fracturing

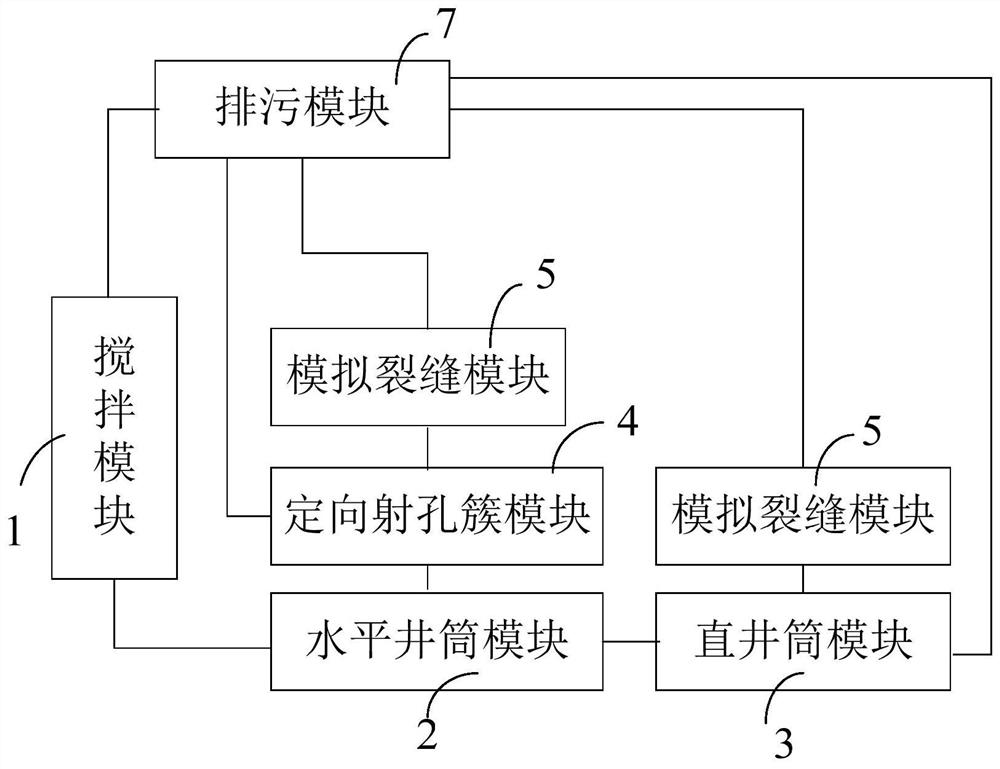

A research-level, temporary plugging agent technology, applied in wellbore/well components, earth-moving drilling, educational tools, etc., can solve problems such as difficulty in exploration and difficulty in knowing the location of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

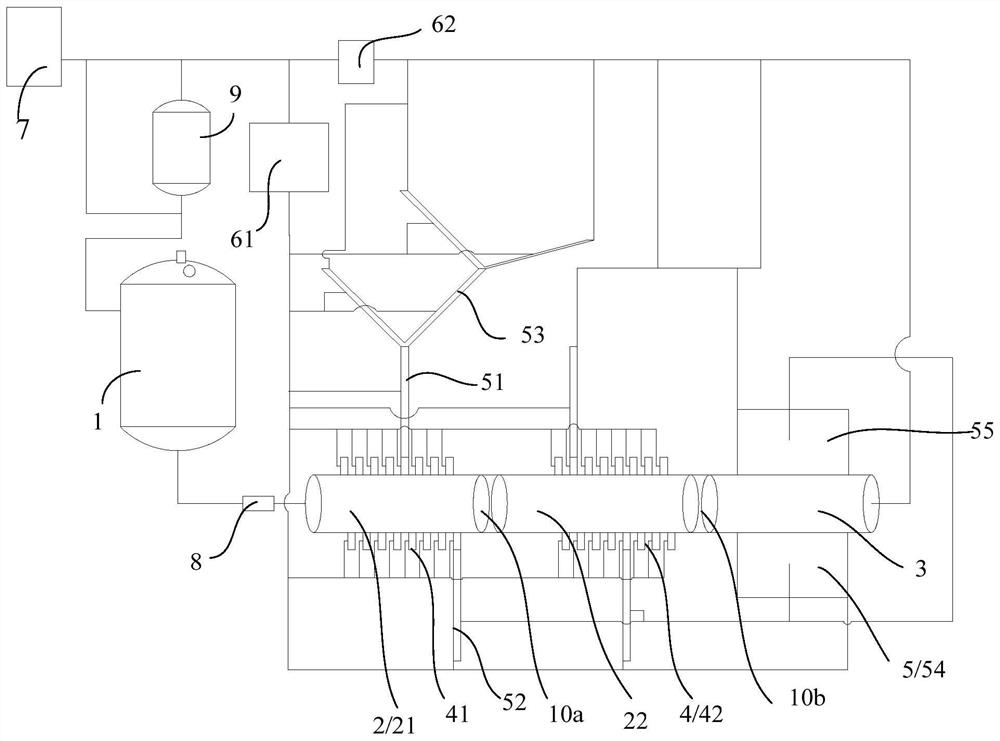

Embodiment 1

[0071] Set the experimental conditions:

[0072] ①Experimental temperature: room temperature

[0073] ②Experimental materials: degradable fiber, 40-70 mesh ceramsite

[0074] ③Experimental fluid: guar gum powder + fiber + temporary plugging agent + water;

[0075] ④Experimental pressure: 0.4Mpa.

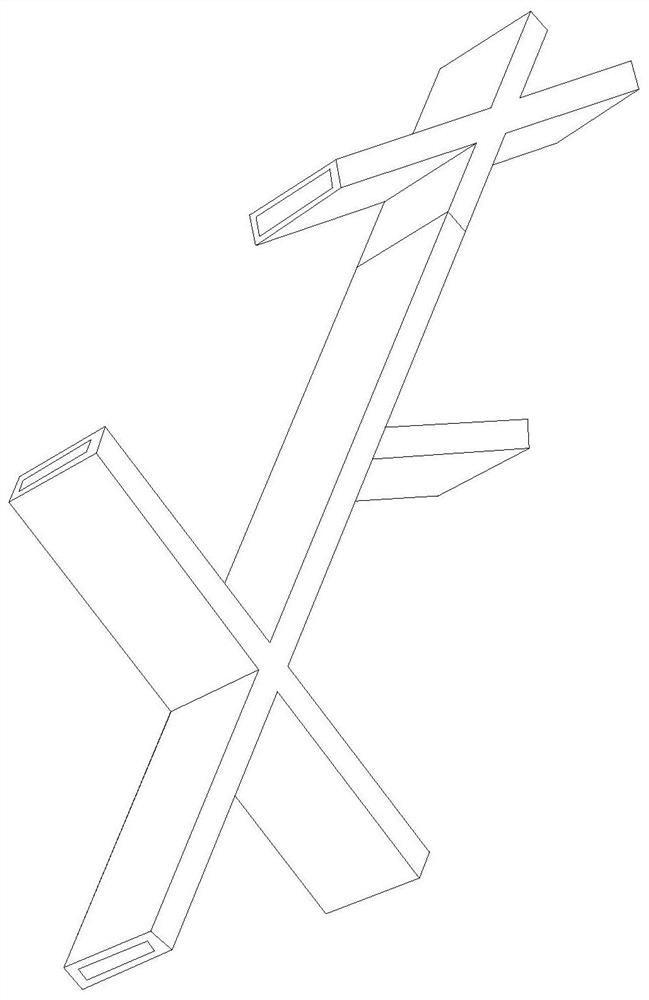

[0076] S1, installation, install a total of 3m first extended wellbore 10a between the two perforation clusters, install 16 perforation holes with a length of 18cm and a diameter of 1.5cm on each perforation cluster; in the directional perforation cluster module The middle perforation hole of the first section 41 of 4 is connected to the first main fracture 51, and the first main fracture 51 is followed by branch fracture groups 53 with included angles of 90°, 135°, and 180° respectively; the working fluid is configured,

[0077] S2, pour tap water into about two-thirds of the cylinder of the stirring tank, weigh 3kg of guar gum, 1kg of fiber, 40kg of proppant, weigh the designed ...

Embodiment 2

[0081] Set the experimental conditions:

[0082] ①Experimental temperature: room temperature

[0083] ②Experimental materials: degradable fiber, 40-70 mesh ceramsite

[0084] ③Experimental fluid: guar gum powder + fiber + temporary plugging agent + water;

[0085] ④Experimental pressure: 0.4Mpa.

[0086] S1, installation, install a total of 3m first extended wellbore 10a in the middle of the two perforation clusters, install 8 perforation holes with a length of 18cm and a diameter of 1.5cm on each perforation cluster, and 8 solid holes with untapped holes Perforation cylinder; the first main fracture 51 is connected to the middle perforation hole of the first section 41 of the directional perforation cluster module 4, and the first main fracture 51 is followed by branch fractures with angles of 90° and 135° respectively Group 53: Glue is applied to the main cracks and branch cracks, and uniformly distributed micro-gravel particles are glued to artificially create a friction...

Embodiment 3

[0091] Set the experimental conditions:

[0092] ①Experimental temperature: room temperature

[0093] ②Experimental materials Degradable fiber, 40-70 mesh ceramsite

[0094] ③Experimental fluid: guar gum powder + fiber + temporary plugging agent + water;

[0095] ④Experimental pressure: 0.4Mpa.

[0096] S1, installation, install a total of 5m first extended wellbore 10a in the middle of the two perforation clusters, install 8 perforation holes with a length of 18cm and a diameter of 1.5cm, and 8 perforations with a length of 18cm and a diameter of 2cm on each perforation cluster The perforation hole of the vertical wellbore module 3 is set upside down; the first main fracture 51 is connected to the middle perforation hole of the first section 41 of the directional perforation cluster module 4, and the first main fracture 51 is followed by an included angle 90° and 135° branch joint groups 53 respectively; the main cracks and branch joints are coated with glue and uniformly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com