A timing chain system and its engine

A timing sprocket and chain technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of reduced matching accuracy, poor lubrication effect of exhaust sprockets, and large movement noise, reducing mechanical wear, Improved lubrication effect and improved fit accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

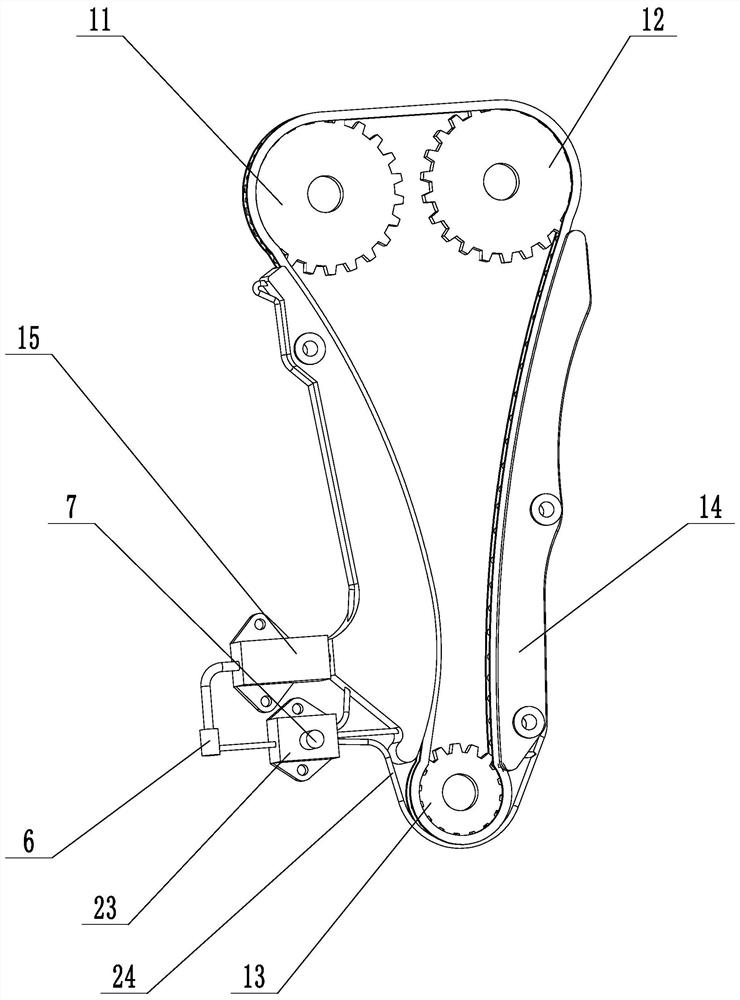

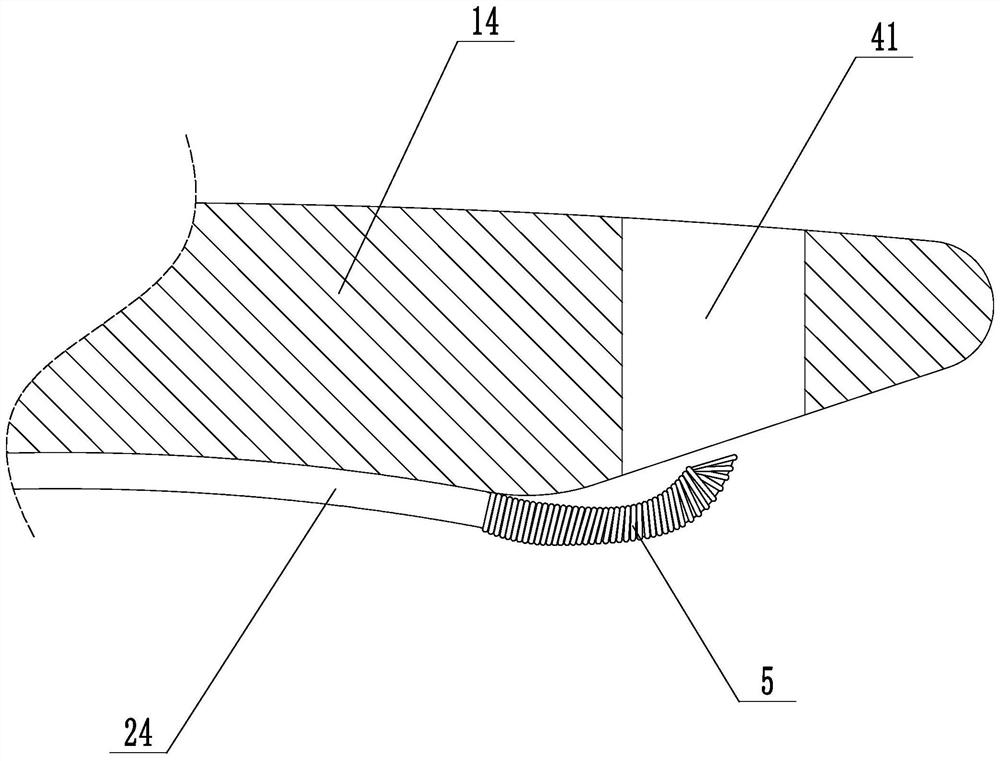

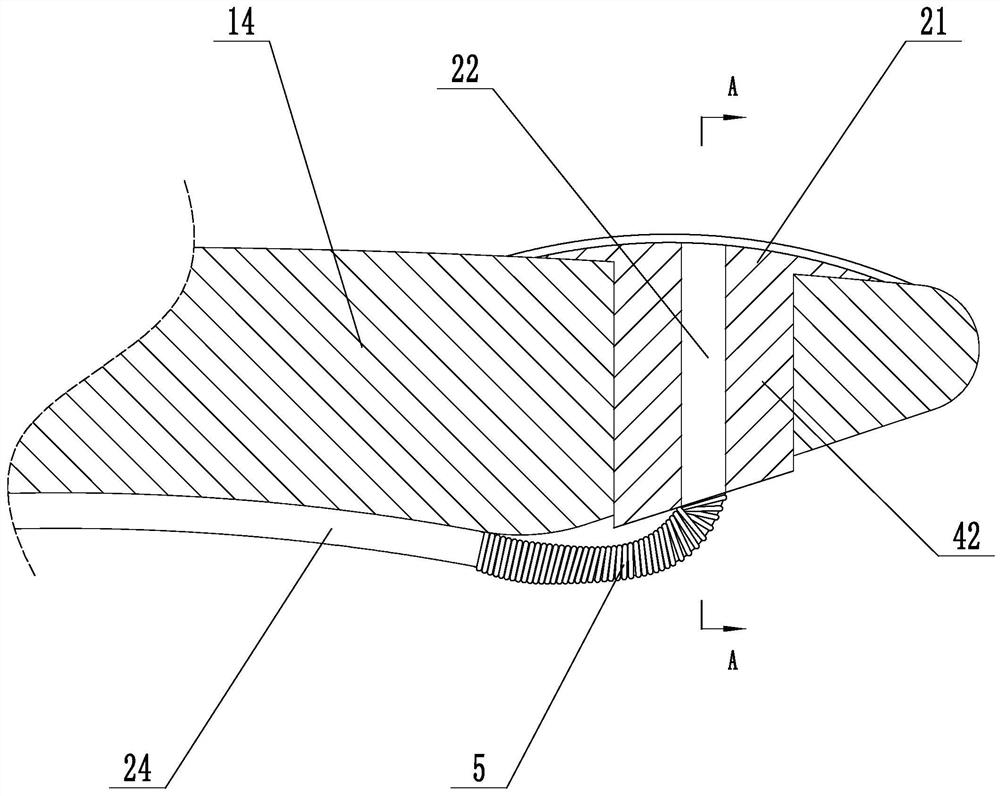

[0043] refer to figure 1 , is a kind of timing chain system and its engine disclosed by the present invention, the timing chain system is mainly composed of intake sprocket 11, exhaust sprocket 12, timing sprocket 13, timing chain guide rail 14, hydraulic tensioner 15 and timing chain 16 etc. are formed. The intake sprocket 11, the exhaust sprocket 12 and the timing sprocket 13 are installed on the intake camshaft, the exhaust camshaft and the engine crankshaft respectively, and the timing chain 16 sequentially connects the three sprockets. The timing chain guide rail 14 is installed in the engine, and its effect is to apply pressure to the timing chain 16 so that it can be in a tensioned state. The timing chain guide rail 14 has two kinds of fixed type and swing type. The fixed type timing chain guide rail 14 is installed in the engine with the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com