Backboard communication method

A backplane and communication technology, applied in the field of backplane communication, can solve problems affecting system stability, control period jitter, communication time fluctuation, etc., and achieve the effect of reducing fault processing time, intelligent processing, and improving system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

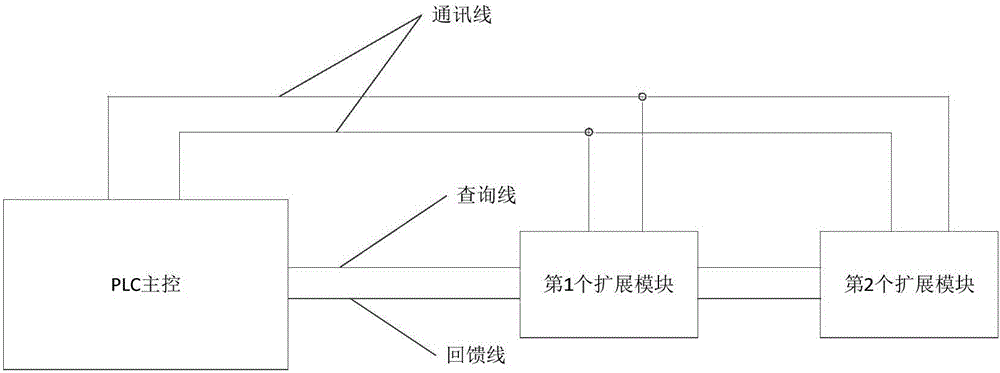

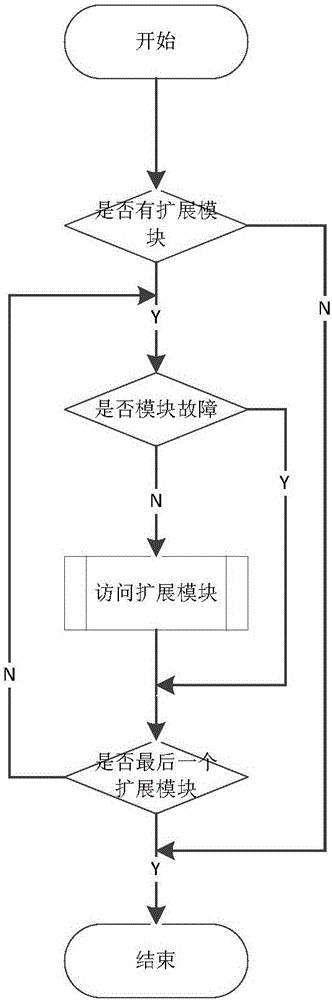

[0013] In this method of backplane communication, the backplane lines between the PLC main control and the expansion module include: communication lines, query lines, and feedback lines; the communication lines are two differential communication lines and the electrical characteristics are RS485, and the communication lines adopt the bus mode Connect all the expansion modules together; the query line and the feedback line are single-wire and the electrical characteristics are 3.3V to the ground, and the query line and the feedback line are connected in a daisy chain; Add a query line and a feedback line. These two signal lines provide such an interaction mechanism for two adjacent expansion modules: the front-level expansion module accesses the state of the subsequent expansion module through the query line, and the latter expansion module through The feedback line responds its own status to the front-end expansion module.

[0014] Since the present invention adds a query line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com