Multitube barium sulfate solution sampling device

A sampling device, barium sulfate technology, applied in the direction of sampling devices, sampling, measuring devices, etc., can solve the problems of control frame hardening, poor assembly, inconvenient liquid extraction, etc., achieve small operating space requirements, shorten production cycle, and sample high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

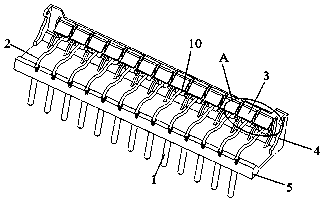

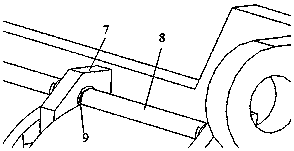

[0017] Compare below Figure 1 to Figure 3 To illustrate, since this device has relatively high requirements on the airtightness of the connection between the airbag 10 and the suction pipe 2 and the front extension frame 5 and the airbag 10, their connection should be checked before work, and the rotation angle of the pressing piece 3 needs to be adjusted next. And the degree of contact with the airbag 10, to avoid uneven extrusion, incomplete exhaust operation errors, and then you can use clear water to test and complete the debugging work of the device, so far the device completes the preparatory work.

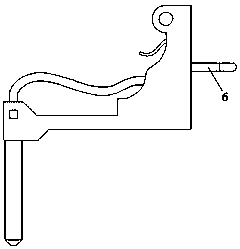

[0018] Before use, the operator installs the liquid suction tube 1 on the lower end of the front extension frame 5, and connects it with the suction pipe 2 through the through hole inside the front extension frame 5, and then rotates the rotary pressure rod 8 to check whether there is any air leakage in the air bag 10. situation, then turn the rotary pressure rod 8, at this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com