Starter Test Bench

A test bench and starter technology, which is applied in engine testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as unrealistic load simulation and insufficient comprehensive testing, and shorten maintenance cycle and maintenance cost Low, meet the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

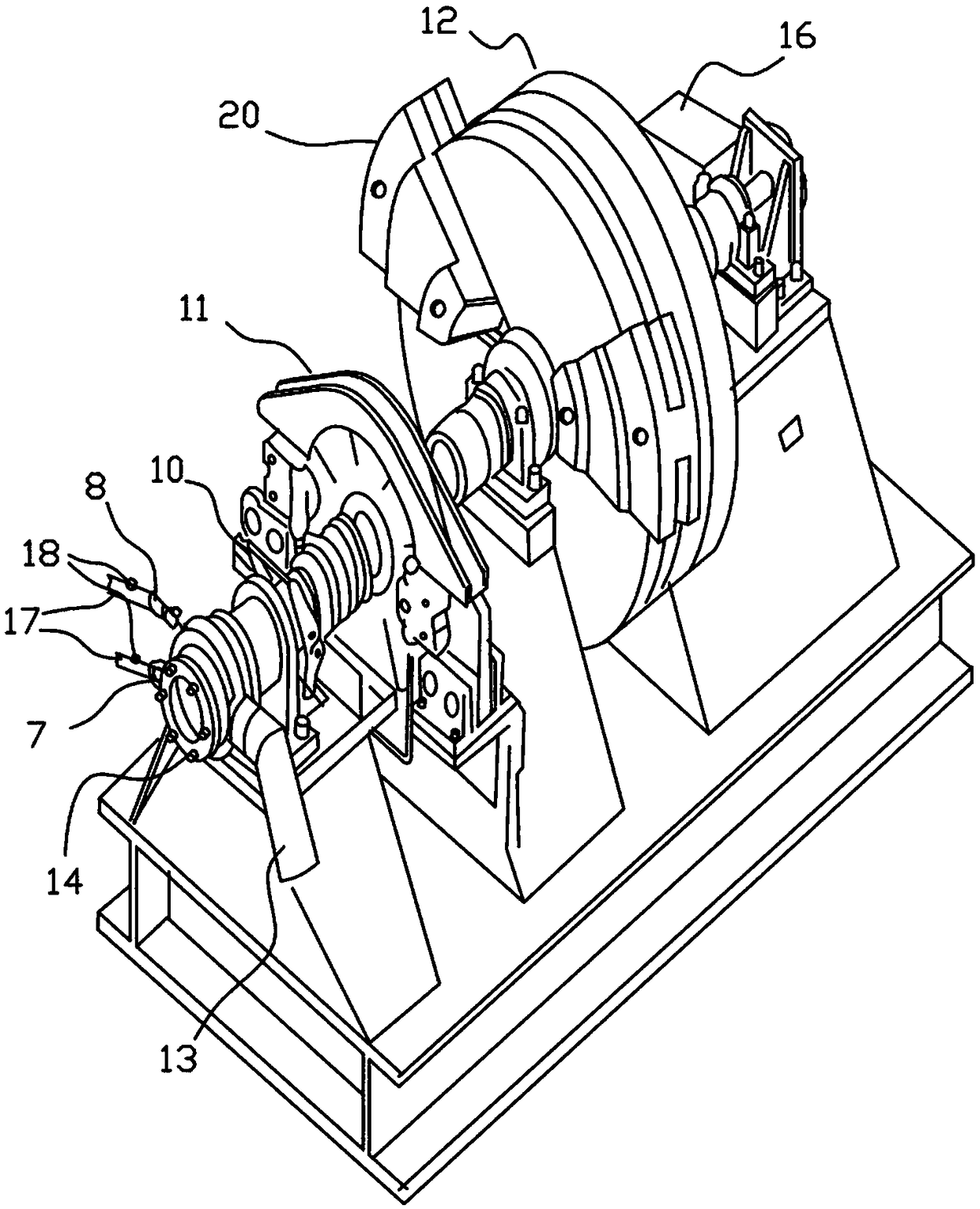

[0031] Yet another embodiment of the present invention: the mounting flange 14 is provided with a first air input port 7 , a second air input port 8 and an exhaust hole 13 . The first air input port 7 and the second air input port 8 are respectively connected with a ventilation pipe 17, the ventilation pipe 17 is provided with a blocking plate, one end of the blocking plate is connected with a rotating screw 18, and the rotating screw 18 Screwed on the vent pipe wall.

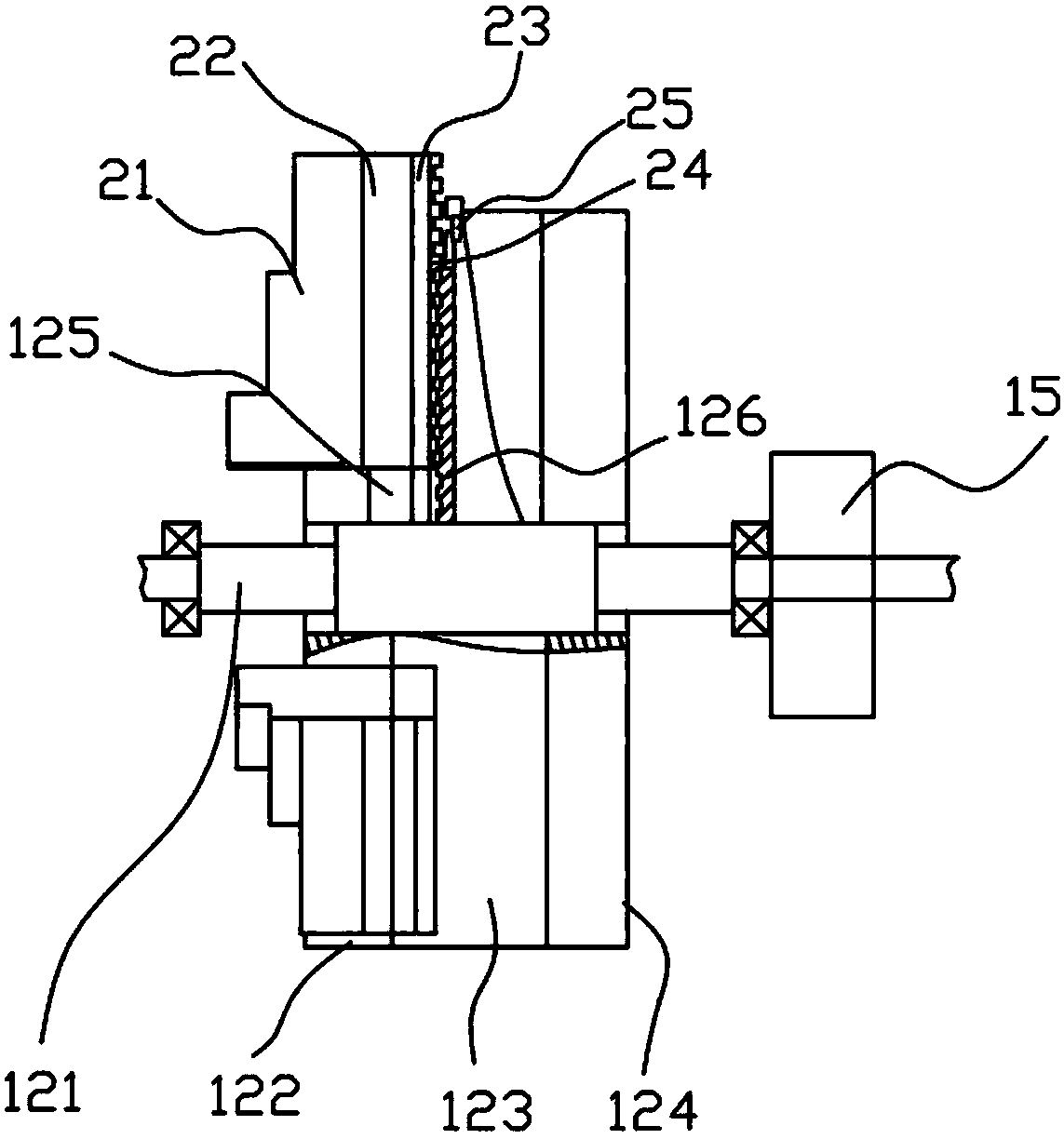

[0032] In addition, another embodiment of the test bench of the present invention, Figure 4 As shown, the output shaft 312 of the air starter is connected to a pipe, and the air intake control system is arranged on the pipe, and the air intake control system includes an air pressure regulator 301 and an electric regulating valve 302 sequentially arranged on the pipe. , pointer pressure gauge 303, flow meter 304, air pressure sensor 305, air temperature sensor 306, shock sensor 308, anti-overspeed sensor 309, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com