A hollow semi-permeable fiber membrane cleaning device

A technology for cleaning device and fiber membrane, applied in the field of spinning, can solve the problems of high construction and operation cost and high operation cost, and achieve the effect of reducing construction height, good cleaning effect and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

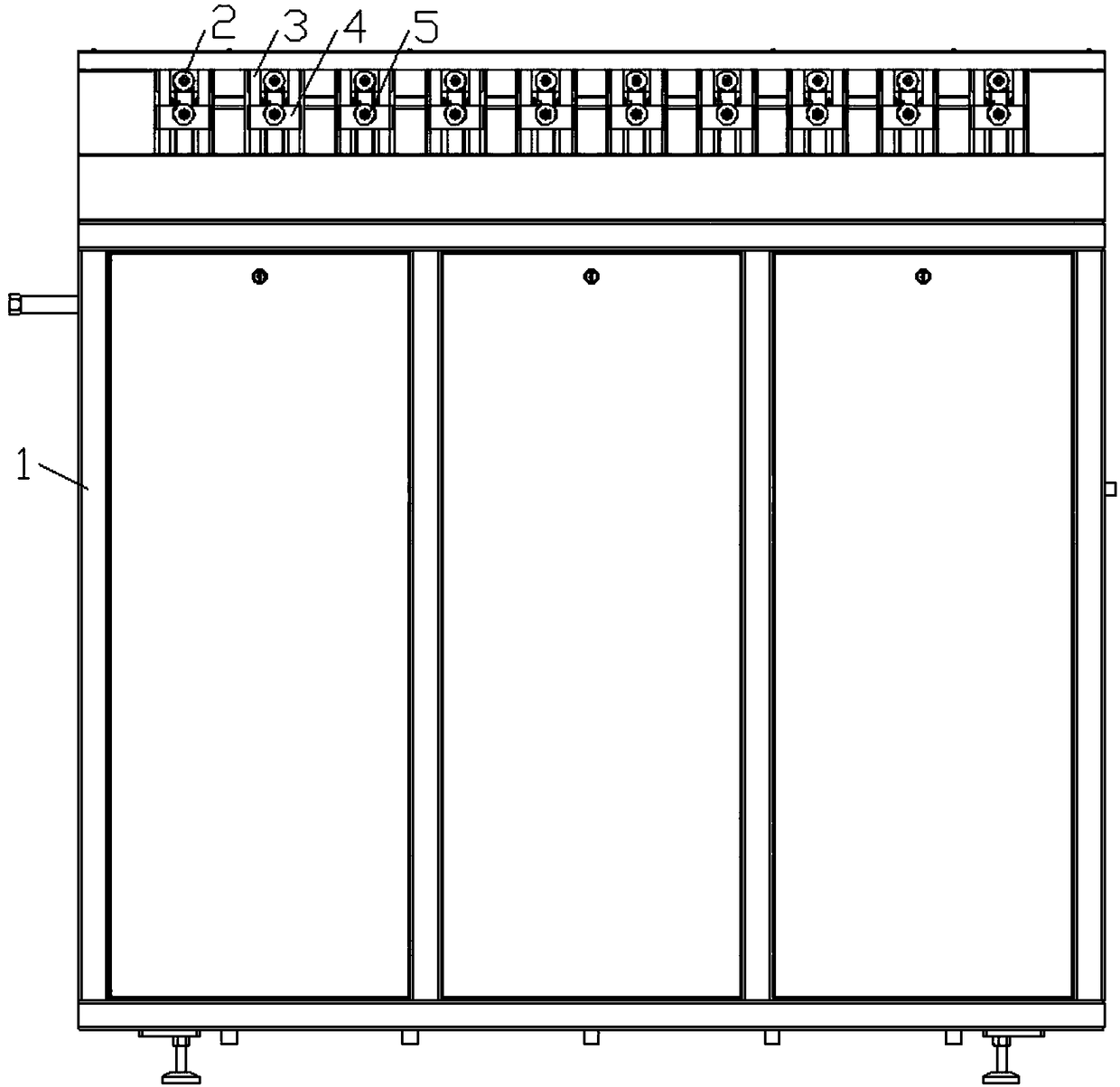

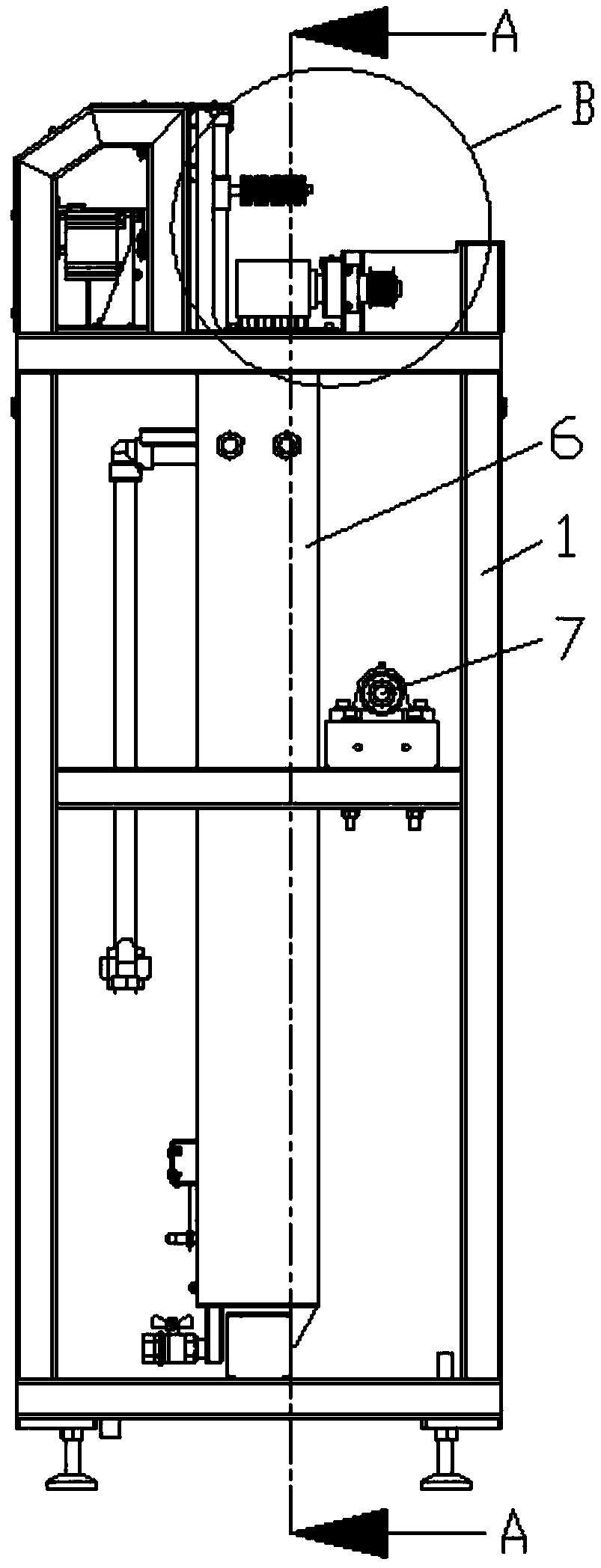

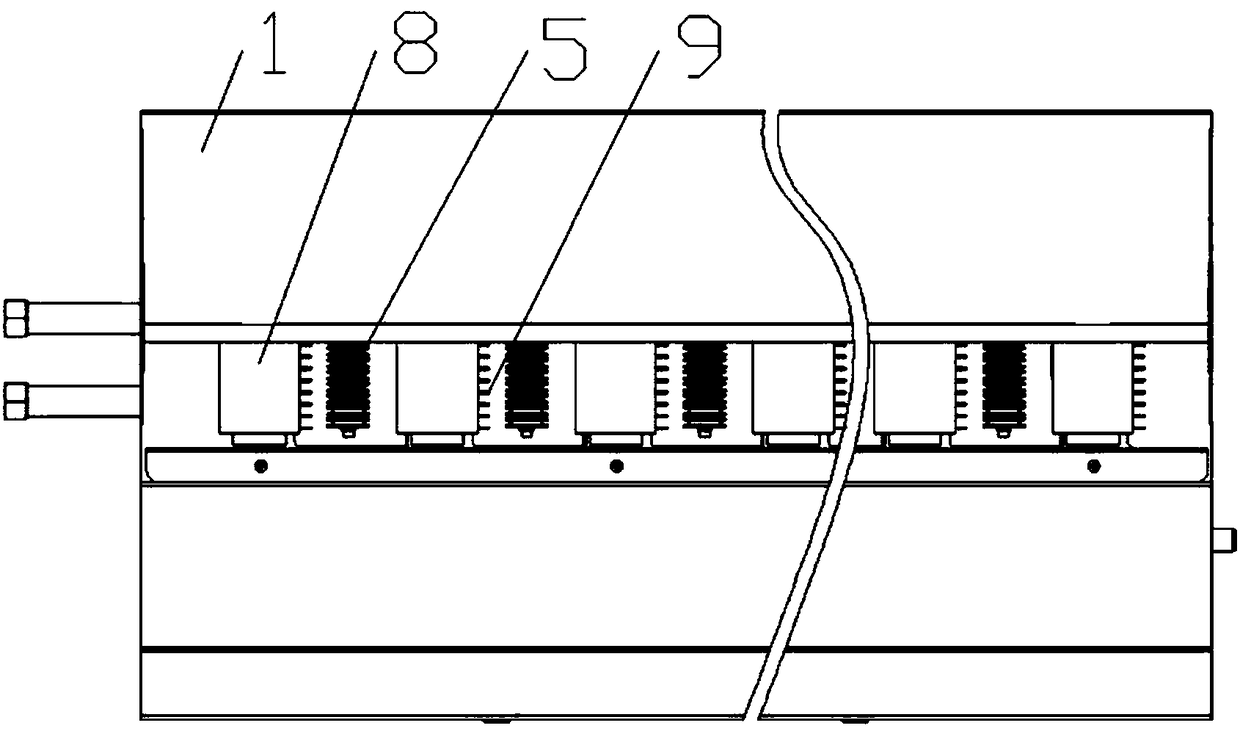

[0039] The cleaning device for hollow semipermeable fiber membranes in this embodiment includes a frame, and the frame is provided with a head-end water washing tank and a tail-end water washing tank, and there are multiple A middle washing tank, the head washing tank is provided with a drain pipe, the tail washing tank is provided with a water inlet pipe, the head washing tank, the middle washing tank and the tail washing tank are connected in sequence and form an "S" shaped flow channel , the water washing tank at the head end, the middle water washing tank and the water washing tank at the tail end form a water tank system that is independent of each other and connected in sequence; wire pressing guide rails are installed on the inner walls of each washing tank, and wire pressing guide rails are installed on the wire pressing guide rails. A sliding wire pressing slider, on which a cantilever pressing wheel for bringing the hollow semi-permeable fiber membrane wire into the b...

Embodiment 2

[0041] The cleaning device for hollow semipermeable fiber membranes in this embodiment includes a frame, and the frame is provided with a head-end water washing tank and a tail-end water washing tank, and there are multiple A middle washing tank, the head washing tank is provided with a drain pipe, the tail washing tank is provided with a water inlet pipe, the head washing tank, the middle washing tank and the tail washing tank are connected in sequence and form an "S" shaped flow channel , the water washing tank at the head end, the middle water washing tank and the water washing tank at the tail end form a water tank system that is independent of each other and connected in sequence; wire pressing guide rails are installed on the inner walls of each washing tank, and wire pressing guide rails are installed on the wire pressing guide rails. Sliding wire pressing slider, on which a cantilever pressing wheel for bringing the hollow semi-permeable fiber membrane wire into the bot...

Embodiment 3

[0043] The cleaning device for hollow semipermeable fiber membranes in this embodiment includes a frame, and the frame is provided with a head-end water washing tank and a tail-end water washing tank, and there are multiple A middle washing tank, the head washing tank is provided with a drain pipe, the tail washing tank is provided with a water inlet pipe, the head washing tank, the middle washing tank and the tail washing tank are connected in sequence and form an "S" shaped flow channel , the water washing tank at the head end, the middle water washing tank and the water washing tank at the tail end form a water tank system that is independent of each other and connected in sequence; wire pressing guide rails are installed on the inner walls of each washing tank, and wire pressing guide rails are installed on the wire pressing guide rails. Sliding wire pressing slider, on which a cantilever pressing wheel for bringing the hollow semi-permeable fiber membrane wire into the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com