Preparation method of essential oil of tangerine peel and application of essential oil of tangerine peel in cigarettes

A technology of tangerine peel essential oil and tangerine peel, which is applied in the directions of preparing tobacco, application, essential oil/spice, etc., to achieve the effects of efficient production process, simple preparation process, and improvement of smoke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

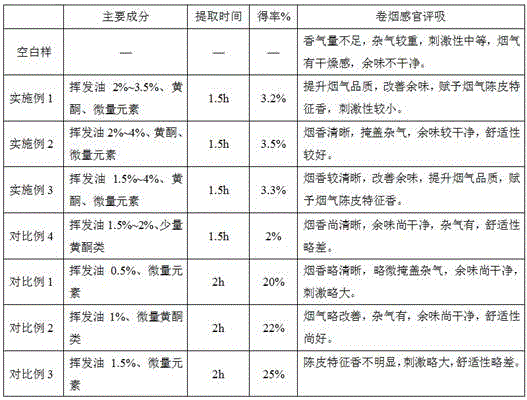

Examples

Embodiment 1

[0024] (1) Crush tangerine peel: crush tangerine peel with a water content of 10% to tangerine peel grains with a particle size of 15mm;

[0025] (2) Fermentation of tangerine peel: take pectinase according to 1.5% of the mass of tangerine peel grains, and take cellulase according to 1.5% of the mass of tangerine peel grains; place the tangerine peel grains obtained in step (1) at a temperature of 30°C and a humidity of 65%. In a constant temperature and humidity environment, add pectinase and cellulase to ferment for 3 days by spraying, and turn the pile every 1 to 2 days to fully decompose the pectin and cellulose in the tangerine peel;

[0026] (3) Distillation: steam distill the tangerine peel grains fermented in step (2) at 100°C, and collect the distillate until the distillate is clear and transparent without any oily matter, then stop the distillation;

[0027] (4) Oil and water separation: the distillate obtained in step (3) is separated from oil and water through a se...

Embodiment 2

[0031] (1) Crush tangerine peel: crush tangerine peel with a water content of 20% to tangerine peel grains with a particle size of 4mm;

[0032] (2) Fermentation of tangerine peel: take pectinase according to 5% of the weight of tangerine peel grains, and take cellulase according to 5% of the weight of tangerine peel grains; place the dried tangerine peel grains obtained in step (1) at a temperature of 40°C and a humidity of 90%. In a constant temperature and humidity environment, add pectinase and cellulase to ferment for 10 days by spraying, and turn the pile every 1 to 2 days to fully decompose the pectin and cellulose in the tangerine peel;

[0033] (3) Distillation: steam distill the tangerine peel grains fermented in step (2) at 110°C, and collect the distillate, and stop the distillation until the distillate is clear and transparent without any oil;

[0034] (4) Oil and water separation: the distillate obtained in step (3) is separated from oil and water through a separ...

Embodiment 3

[0038] (1) Crush tangerine peel: crush tangerine peel with a water content of 70% to 0.1mm tangerine peel grains;

[0039] (2) Fermentation of tangerine peel: take pectinase according to 0.1% of the mass of tangerine peel grains, and take cellulase according to 0.1% of the mass of tangerine peel grains; place the tangerine peel grains obtained in step (1) in a room with a temperature of 60°C and a humidity of 60%. In a constant temperature and humidity environment, add pectinase and cellulase to ferment for 1 day by spraying, and turn the pile every 1 to 2 days to fully decompose the pectin and cellulose in the tangerine peel;

[0040] (3) Distillation: steam distill the tangerine peel grains fermented in step (2) at 120°C, and collect the distilled liquid until the distilled liquid is clear and transparent without any oily matter, then stop the distillation;

[0041] (4) Oil and water separation: the distillate obtained in step (3) is separated from oil and water through a se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com