Coal poly-generation efficient and pyrolysis-gasification series system and pyrolysis gasification method

A series system and pyrolysis gasification technology, which is applied in the high-efficiency pyrolysis-gasification series system of coal polygeneration and the field of pyrolysis gasification, can solve the problem of high dust content in pyrolysis tar and reduce pollution emissions , Guarantee the quality of tar, save the effect of quenching equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with specific embodiments.

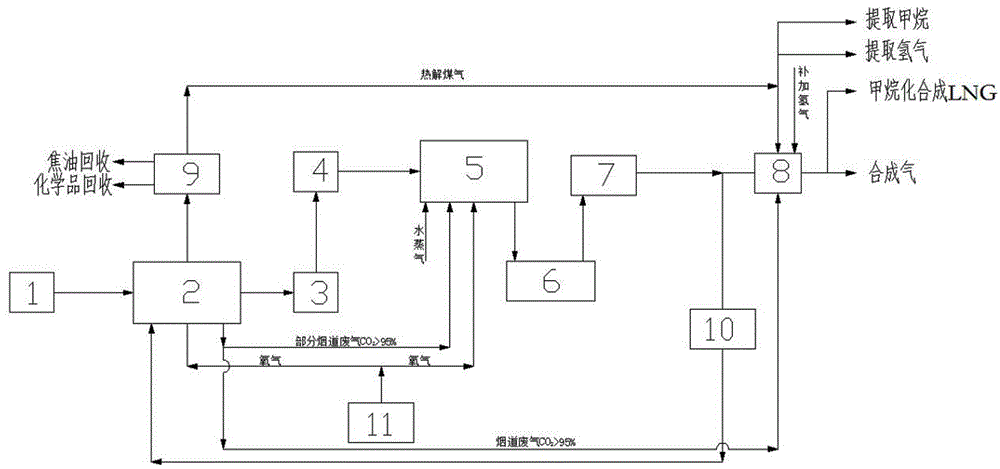

[0027] A high-efficiency pyrolysis-gasification series system for polygeneration of coal, comprising sequentially connected coal blending device 1, coke oven 2, coke transfer device 3, coke lifting device 4, lump coal gasification reactor 5, waste heat boiler 6, Gasification coal gas purification device 7 and gas reforming device 8; described coke oven 2 is also connected with the inlet end of pyrolysis gas purification device 9, and the outlet end of pyrolysis gas purification device 9 is connected with gas reforming device 8; The gasification gas purification device 7 is also connected to the furnace gas holder 10; the coke oven 2 and the lump coal gasification reactor 5 are respectively connected to the air separation device 11 to obtain oxygen.

[0028] In order to make the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com