Composite multi-functional two-component aqueous wood white top coat and preparation method thereof

A two-component, multi-functional technology that is used in biocide-containing paints, antifouling/underwater coatings, coatings, etc. In addition to formaldehyde, stain resistance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

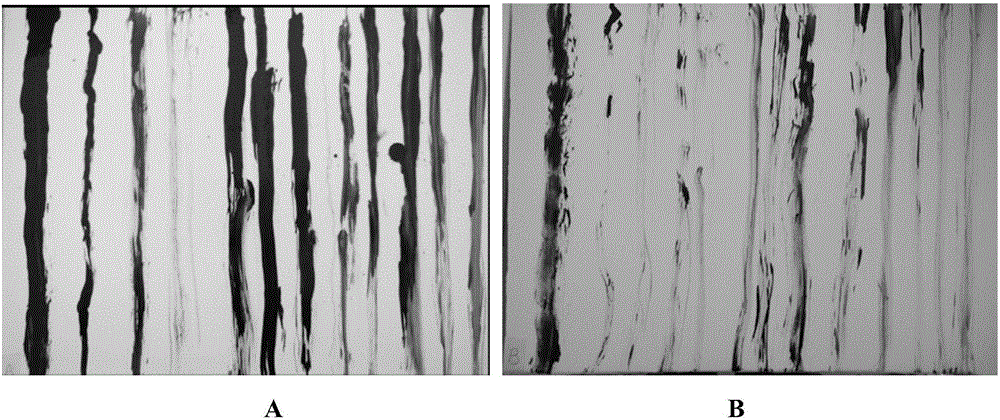

Image

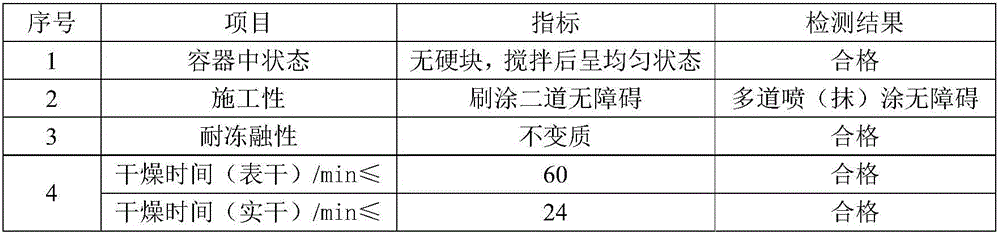

Examples

Embodiment 1

[0080] The composite multi-functional two-component water-based wood white finish provided by this embodiment includes component A, component B and water, and the mass ratio of component A, component B and water is 100:20:20, specifically Formula can be formulated as follows (mass percentage composition):

[0081] A component:

[0082] Waterborne Hydroxy Acrylic Resin 30%

[0083] Composite modified self-crosslinking acrylic polymer 30%

[0084] Water-based titanium dioxide paste 25%

[0085] Water-based matting agent 3%

[0086] Defoamer 0.5%

[0087] Wetting agent 0.3%

[0088] Thickener 0.5%

[0089] Dispersant 0.5%

[0090] Leveling agent 0.2%

[0091] Anti-mildew fungicide 3%

[0092] water 7%,

[0093] The sum of the mass percentages of each raw material in Group A is 100%;

[0094] Component B

[0095] Hydrophilic aliphatic polyisocyanate 75%,

[0096] Propylene glycol methyl ether acetate (PMA) 25%

[0097] The sum of the mass percentages of each raw mate...

Embodiment 2

[0124] The composite multi-functional two-component water-based wood white finish provided by this embodiment includes component A, component B and water, and the mass ratio of component A, component B and water is 100:22:15, specifically Formula can be formulated as follows (mass percentage composition):

[0125] A component:

[0126] Waterborne Hydroxy Acrylic Resin 35%

[0127] Composite modified self-crosslinking acrylic polymer 25%

[0128] Water-based titanium dioxide 28%

[0129] Water-based matting agent 2.5%

[0130] Defoamer 0.4%

[0131] Wetting agent 0.4%

[0132] Thickener 0.7%

[0133] Dispersant 0.5%

[0134] Leveling agent 0.3%

[0135] Anti-mildew fungicide 2.5%

[0136] Water 4.7%,

[0137] The sum of the mass percentages of each raw material in Group A is 100%;

[0138] Component B

[0139] Hydrophilic aliphatic polyisocyanate 73%,

[0140] Propylene glycol methyl ether acetate (PMA) 27%

[0141] The sum of the mass percentages of each raw mate...

Embodiment 3

[0153] The composite multi-functional two-component water-based wood white finish provided in this embodiment includes component A, component B and water, and the mass ratio of component A, component B and water is 100:25:10, specifically Formula can be formulated as follows (mass percentage composition):

[0154] A component:

[0155] Waterborne Hydroxy Acrylic Resin 40%

[0156] Composite modified self-crosslinking acrylic polymer 20%

[0157] Water-based titanium dioxide paste 25%

[0158] Water-based matting agent 2%

[0159] Defoamer 0.3%

[0160] Wetting agent 0.3%

[0161] Thickener 0.5%

[0162] Dispersant 0.5%

[0163] Leveling agent 0.2%

[0164] Anti-mildew fungicide 2%

[0165] Water 9.2%,

[0166] The sum of the mass percentages of each raw material in Group A is 100%;

[0167] B component;

[0168] Hydrophilic aliphatic polyisocyanate 70%,

[0169] Propylene glycol methyl ether acetate (PMA) 30%

[0170] The sum of the mass percentages of each raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com