Novel casting rust-preventing cover layer and preparation method thereof

A covering layer, a new type of technology, applied in the field of new cast anti-rust covering layer and its preparation, can solve the problems of easy damage and unsatisfactory anti-rust effect, achieve anti-rust, strong strength and flexibility, simple and reliable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

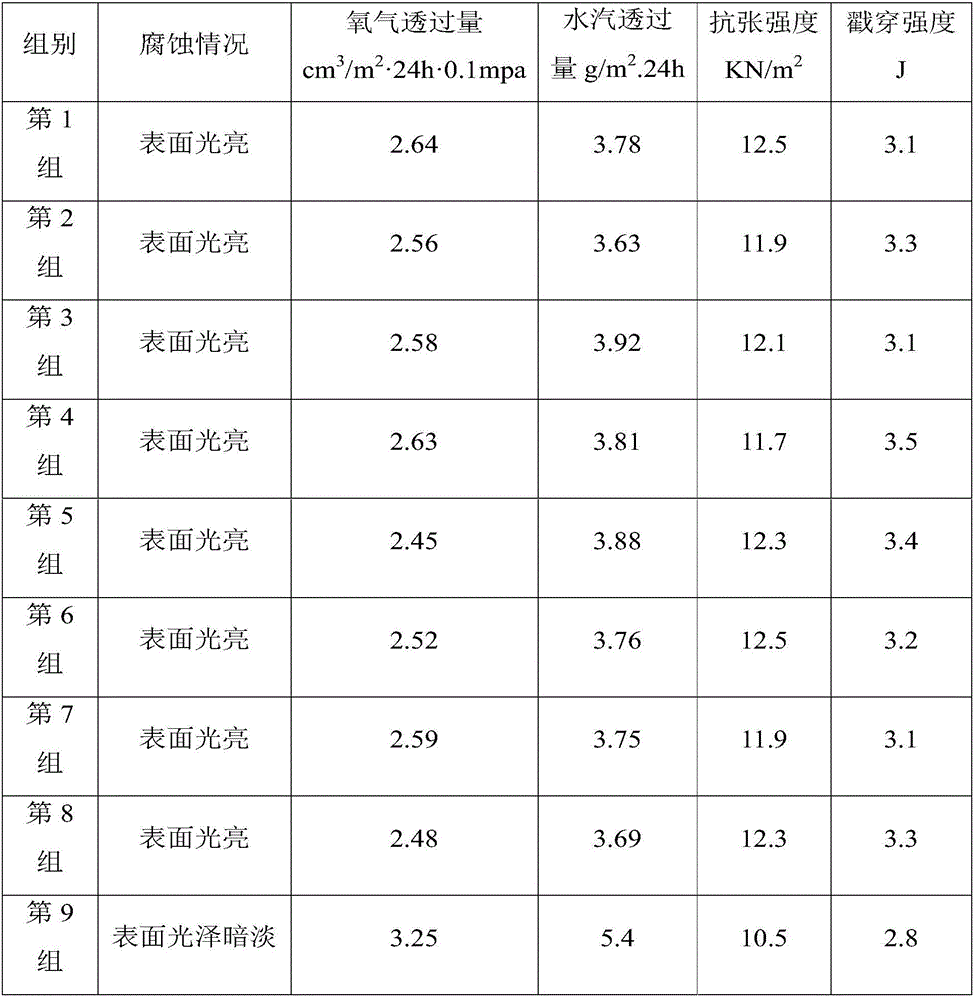

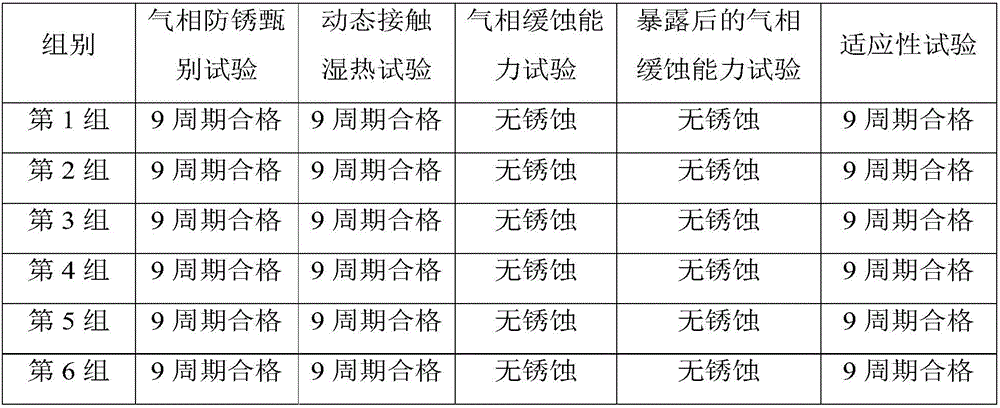

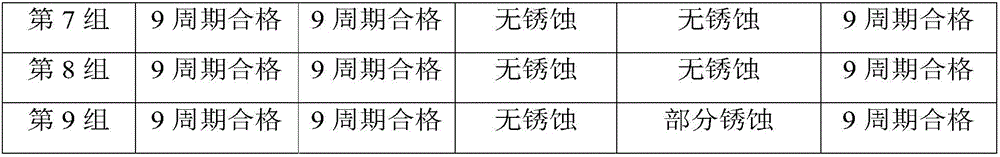

Examples

preparation example Construction

[0030] The embodiment of the present invention also provides a method for preparing the above-mentioned novel cast anti-rust covering layer, comprising the following steps:

[0031] S1. Prepare raw materials: 15-75 parts of polyethylene, 15-75 parts of polypropylene, 3-5 parts of dispersant, 2-5 parts of slip agent, 5-10 parts of anti-rust masterbatch.

[0032]S2. Mix polyethylene, polypropylene and antirust masterbatch evenly to obtain a base material; add a dispersant and a slip agent to the base material, and stir evenly to obtain a mixture;

[0033] S3. Put the mixture into the extruder to extrude and cool to obtain a novel cast anti-rust coating; wherein, the temperature in the extruder is 120-190°C, and the temperature at the extrusion die of the extruder is The temperature is 190-280°C, the speed of the extruder is 20-200m / min, and the weight of the new cast-type anti-rust coating is 10-100g / m 2 .

[0034] When the base material is composed of 70-75 parts of polyethyl...

Embodiment 1

[0039] The present embodiment provides a novel casting type antirust coating, and its preparation method is as follows:

[0040] Prepare raw materials: 15kg polyethylene, 75kg polypropylene, 2kg disodium sebacate, 2kg sodium molybdate, 2kg salicylic hydroxamic acid, 2kg carboxymethyl cellulose, 1kg polyethylene wax, 1kg erucamide, 1kg polyethylene glycol laurate.

[0041] Mix 15kg polyethylene, 75kg polypropylene, 2kg disodium sebacate, 2kg sodium molybdate, and 2kg salicylic hydroxamic acid to obtain a substrate; add 2kg carboxymethylcellulose, 1kg polyethylene wax, 1kg Erucamide and 1kg polyethylene glycol laurate are stirred evenly to obtain a mixture; the mixture is put into an extruder to extrude and cool to obtain a novel casting type antirust coating; wherein, the temperature in the extruder is 150°C, the temperature at the extrusion die of the extruder is 240°C, the speed of the extruder is 180m / min, and the gram weight of the new casting type antirust coating is 47g / ...

Embodiment 2

[0043] The present embodiment provides a novel casting type antirust coating, and its preparation method is as follows:

[0044] Prepare raw materials: 30kg polyethylene, 50kg polypropylene, 2kg disodium sebacate, 2kg sodium molybdate, 3kg sodium octadecanoate, 3kg salicylic hydroxamic acid, 2kg carboxymethyl cellulose, 1kg polyethylene wax, 1kg erucamide , 1kg Fischer-Tropsch wax, 2kg polyethylene glycol laurate.

[0045] Mix 30kg polyethylene, 50kg polypropylene, 2kg disodium sebacate, 2kg sodium molybdate, 3kg sodium octadecanoate, and 3kg salicylic hydroxamic acid to obtain a base material; add 2kg carboxymethyl cellulose, 1kg polyethylene wax, 1kg erucamide, 1kg Fischer-Tropsch wax, 2kg polyethylene glycol laurate, and stir evenly to obtain a mixture; put the mixture into an extruder to extrude and cool to obtain a new cast type antirust Covering layer; wherein, the temperature in the extruder is 165°C, the temperature at the extrusion die of the extruder is 190°C, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com