Industrial production method of exemestane

A production method, exemestane technology, applied in the field of organic synthesis, can solve the problems of unsuitability for industrial production, unstable quality, low yield, etc., and achieve the effect of cheap raw material sources, easy control of process operation, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

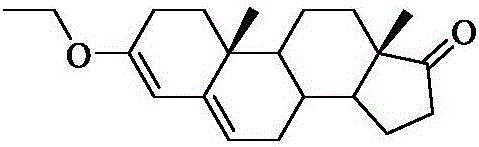

[0011] 1. Preparation of intermediate YXMT01:

[0012] Add 4Kg of 1,4-androsdienedione, 4L of triethyl orthoformate, 104g of p-toluenesulfonic acid, 26L of tetrahydrofuran, and 4L of absolute ethanol, raise the temperature to 40--45°C and stir for 12 hours to detect that the remaining raw materials do not exceed 5.0 % stop, then filter, add 15L ethanol for recrystallization, obtain 3.45Kg white solid intermediate YXMT01, purity 98.5%, yield range 78.3%, intermediate YXMT01 structural formula is as follows:

[0013]

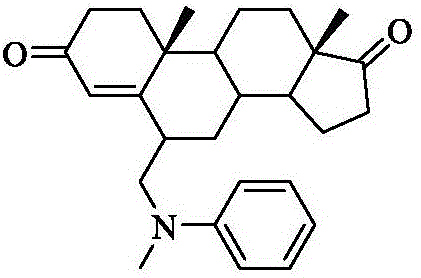

[0014] 2. Preparation of intermediate YXMT02:

[0015] Add 3.45KgYXMT01, 10L tetrahydrofuran, 10L ethanol, 1.76Kg N-methylaniline and 0.87Kg37% formaldehyde and stir for 10 hours under the condition of at least 40--45°C, check that the remaining raw materials do not exceed 3.0%, stop, distill off the solvent, and drop directly One-step reaction, without refining, obtain 3.25Kg intermediate YXMT02, purity 98.9%, yield range 73.5%, intermediate YXMT02 structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com