Granite powder composite mineral admixture and preparation method therefor

A technology for granite rock powder and composite minerals, which is applied in the field of granite rock powder composite mineral admixture and its preparation, can solve the problems of low dosage, and achieve the effects of increasing dosage, improving workability and reducing surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare modified granite stone powder: take granite stone powder and composite modifier as raw materials, get the composite modifier that accounts for 1% of the quality of granite stone powder (by mass percentage by 60% alkaline activator and 40% sulfate activator Composition, wherein the basic activator is water glass, the modulus is 2.3, the sulfate activator is phosphogypsum, CaSO 4 2H 2 The content of O is 90.5%), and then the granite stone powder and the composite modifier are mixed and ground until the screening amount of the 200-mesh square hole sieve is less than 30%, so as to obtain the modified granite stone powder.

[0028] Preparation of modified fly ash: Mix fly ash and quicklime at a mass ratio of 9:1, hydrothermally treat at 100°C for 24 hours, dry and calcinate at 900°C for 1 hour, and then quench to obtain.

[0029] Preparation of granite stone powder composite mineral admixture: take by weight 40 parts of modified granite stone powder, 25 parts of mod...

Embodiment 2

[0031] A method similar to that of Example 1 was used to prepare modified granite rock powder and modified fly ash.

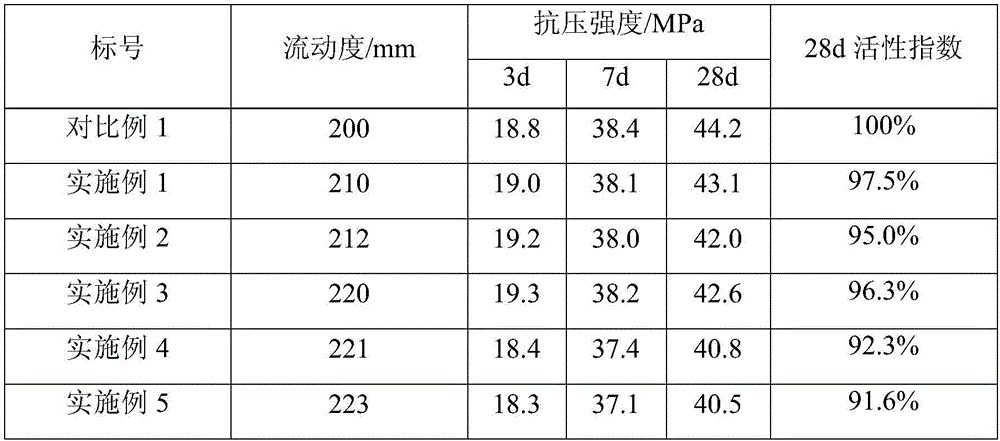

[0032]Preparation of granite stone powder composite mineral admixture: take 50 parts of modified granite stone powder, 25 parts of modified fly ash, and 25 parts of slag according to the mass ratio, and take a strengthening activator (same as Example 1), and the strengthening activator is added The amount accounts for 0.2% of the sum of the mass of granite stone powder, modified fly ash and slag. The above raw materials are put into a ball mill and ground until the sieve volume of a 45 μm square hole sieve is less than 10%, and the obtained under-sieve material is dried and cooled to obtain a granite stone powder composite mineral admixture. Apply the granite stone powder composite mineral admixture to the cement mortar (see Table 1 for specific proportions), replace 30% of the cement with the granite stone powder composite admixture, and check the fluidity and...

Embodiment 3

[0034] A method similar to that of Example 1 was used to prepare modified granite rock powder and modified fly ash.

[0035] Preparation of granite stone powder composite mineral admixture: weigh 66.6 parts of modified granite stone powder, 16.7 parts of modified fly ash, 16.7 parts of slag according to the mass ratio, and take a strengthening activator (same as Example 1), and the strengthening activator is added The amount accounts for 0.2% of the sum of the mass of granite stone powder, modified fly ash and slag. The above raw materials are put into a ball mill and ground until the sieve volume of a 45 μm square hole sieve is less than 10%, and the obtained under-sieve material is dried and cooled to obtain a granite stone powder composite mineral admixture. Apply the granite stone powder composite mineral admixture to the cement mortar (see Table 1 for specific proportions), replace 30% of the cement with the granite stone powder composite admixture, and check the fluidity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com