Steel industry sewage hexavalent chromium pollution composite resin adsorbent and preparation method thereof

A steel industry, composite resin technology, applied in the direction of water pollutants, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of high cost of biological treatment, unsuitable for promotion and use, unstable treatment rate, etc., to achieve The treatment effect is good, the effluent water quality is good, and the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

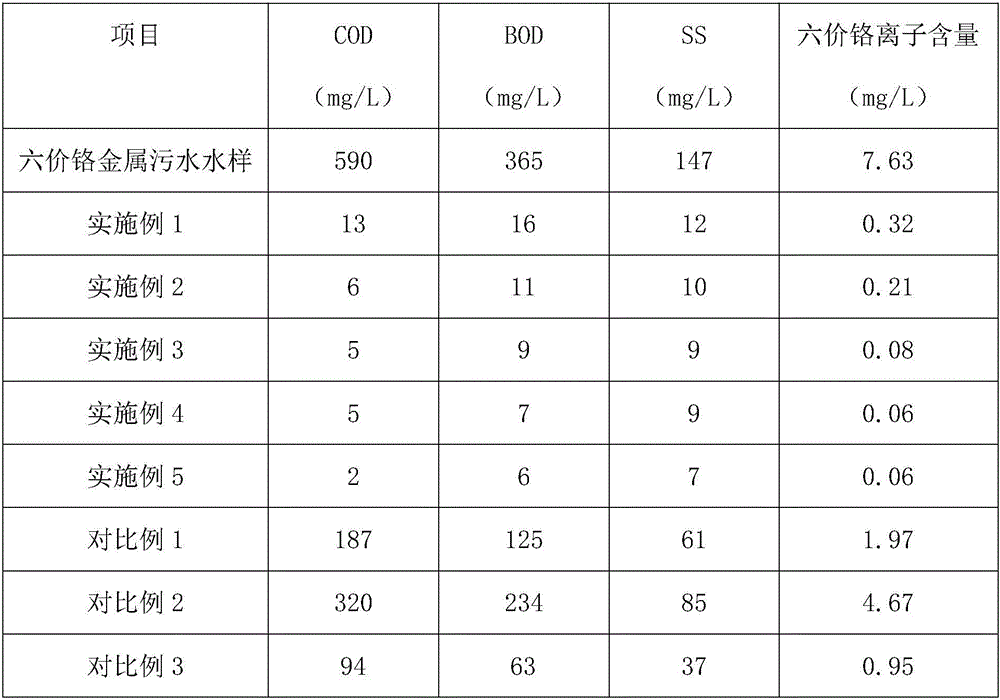

Examples

Embodiment 1

[0020] A composite resin adsorbent for hexavalent chromium pollution in iron and steel industrial sewage, the main raw materials in parts by weight are: 30 parts of modified resin, 10 parts of biofilm of Pseudomonas mieteri CGMCC No.1.6424, 5 parts of polyphosphorus ferric chloride part, 5 parts of sodium tripolyphosphate, 2 parts of sodium metaaluminate, and 0.4 part of sodium lauryl sulfate; the preparation method of the modified resin is: immersing ethacrylic acid resin in lauryl betaine, After soaking for 6 hours, transfer it to a reaction kettle, add tert-butoxycarbonyl-3-pyrrolidone, methyl formate, polyvinyl alcohol and sodium borate, react at 60°C for 0.5 hours under 0.5MPa pressure, and then dry it.

[0021] The preparation method of the Pseudomonas mieteri CGMCC No.1.6424 biofilm is to culture Pseudomonas mieti in the tryptone soybean broth with ammonium lactate added, after static cultivation for 48h, wash with normal saline, and vacuum dry That's it.

[0022] The ...

Embodiment 2

[0028] A composite resin adsorbent for hexavalent chromium pollution in iron and steel industrial sewage, the main raw materials in parts by weight are: 32 parts of modified resin, 11 parts of biofilm of Pseudomonas mieteri CGMCC No.1.6424, 5 parts of polyphosphorus ferric chloride part, 5 parts of sodium tripolyphosphate, 2 parts of sodium metaaluminate, and 0.4 part of sodium lauryl sulfate; the preparation method of the modified resin is: immersing ethacrylic acid resin in lauryl betaine, After soaking for 6 hours, transfer it to a reaction kettle, add tert-butoxycarbonyl-3-pyrrolidone, methyl formate, polyvinyl alcohol and sodium borate, react at 60°C for 0.5 hours under 0.5MPa pressure, and then dry it.

[0029] The preparation method of the Pseudomonas mieteri CGMCC No.1.6424 biofilm is to culture Pseudomonas mieti in the tryptone soybean broth with ammonium lactate added, after static cultivation for 48h, wash with normal saline, and vacuum dry That's it.

[0030] The ...

Embodiment 3

[0036] A composite resin adsorbent for hexavalent chromium pollution in iron and steel industrial sewage, the main raw materials in parts by weight are: 35 parts of modified resin, 13 parts of biofilm of Pseudomonas mieteri CGMCC No.1.6424, 7 parts of polyphosphorus ferric chloride part, 7 parts of sodium tripolyphosphate, 4 parts of sodium metaaluminate, and 0.6 part of sodium lauryl sulfate; the preparation method of the modified resin is: immersing ethylacrylic acid resin in lauryl betaine, After soaking for 6 hours, transfer it to a reaction kettle, add tert-butoxycarbonyl-3-pyrrolidone, methyl formate, polyvinyl alcohol and sodium borate, react at 64°C for 0.5 hours under a pressure of 0.5 MPa, and then dry it.

[0037] The preparation method of the Pseudomonas mieteri CGMCC No.1.6424 biofilm is to culture Pseudomonas mieti in the tryptone soybean broth with ammonium lactate added, after static cultivation for 48h, wash with normal saline, and vacuum dry That's it.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com