Low-floor articulated railway vehicle bogie frame and bogie

A rail vehicle, articulated technology, applied in the direction of bogies, railway car body parts, transportation and packaging, etc., can solve the problems of difficult to get on and off the floor, poor passing ability of small curves, limited vehicle bogies, etc., to avoid Welding stress concentration, reasonable and compact frame structure, and the effect of reducing the amount of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

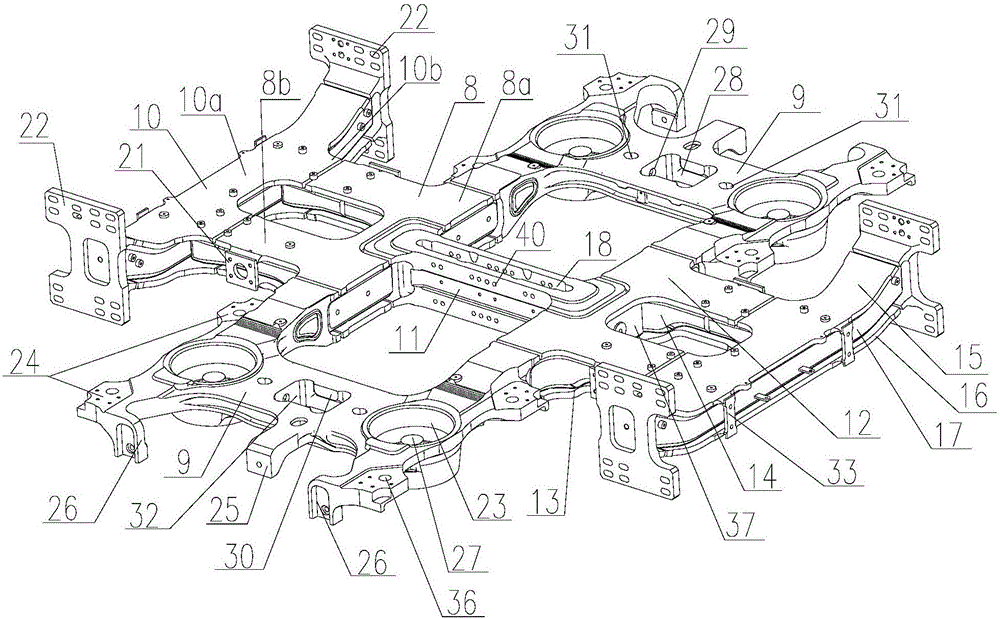

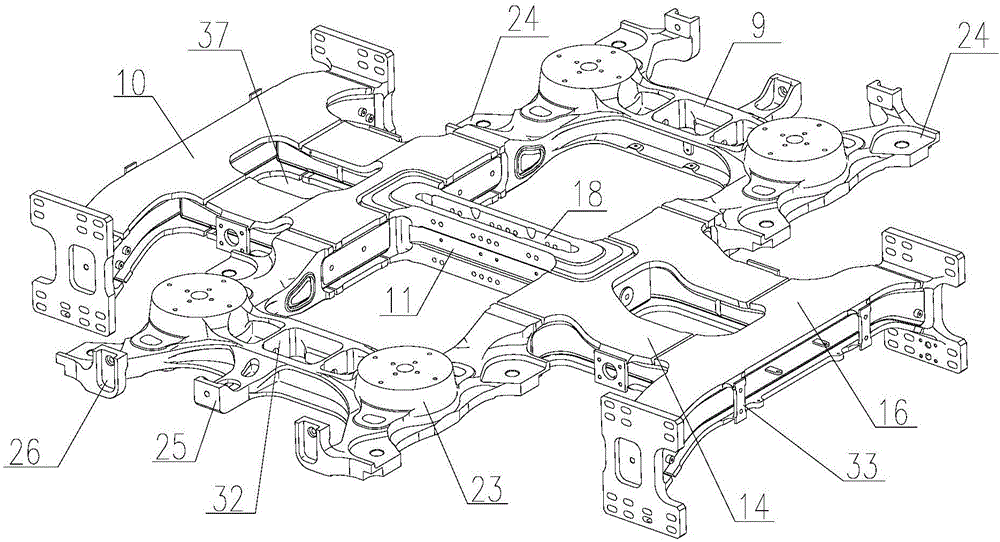

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

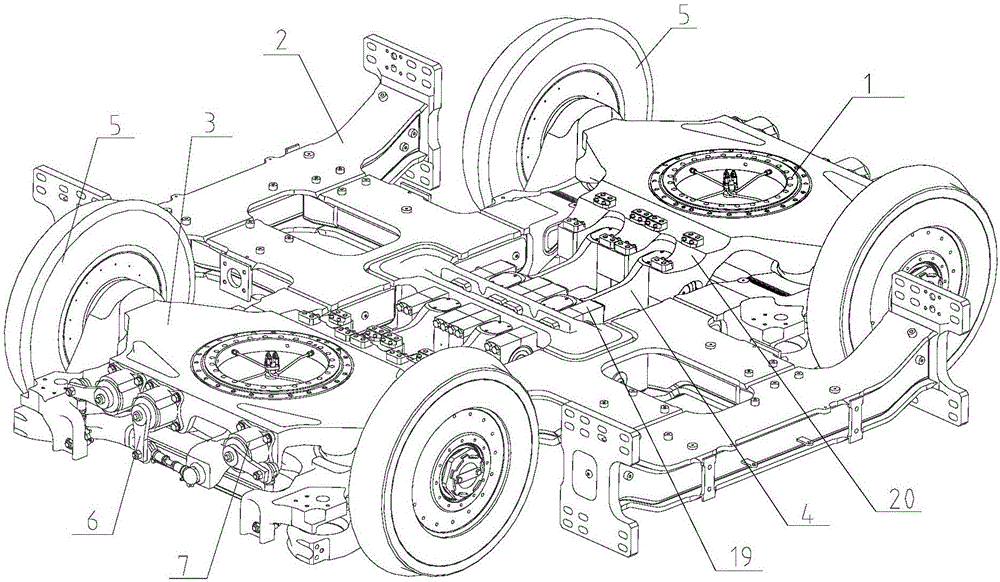

[0030] Such as figure 1 As shown, a low-floor articulated rail vehicle bogie is installed on a low-floor articulated rail vehicle, and a bogie is installed below the junction of every two carriages, and the two carriages are respectively connected to the bogie through a slewing mechanism 1 .

[0031] The bogie consists of a frame 2, two bolsters 3, two sets of traction rods 4, two sets of wheels 5, four driving motors, two sets of magnetic track brakes, two sets of axle bridges, eight primary springs, four secondary The four driving motors independently drive the four wheels, and a set of slewing mechanism 1 is installed on the two bolsters 3, and the two bolsters 3 are respectively installed in the middle of the two sets of wheels 5, and each set of traction rods The two ends of 4 are respectively fixedly connected with the bolster 3 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com