Shield tunneling machine drive box and production method thereof

A technology of drive box and shield machine, which is applied in the fields of manufacturing tools, earth-moving drilling, mining equipment, etc., can solve the problems of welding deformation of drive box and cracking of welding seam of heavy forgings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be defined more clearly.

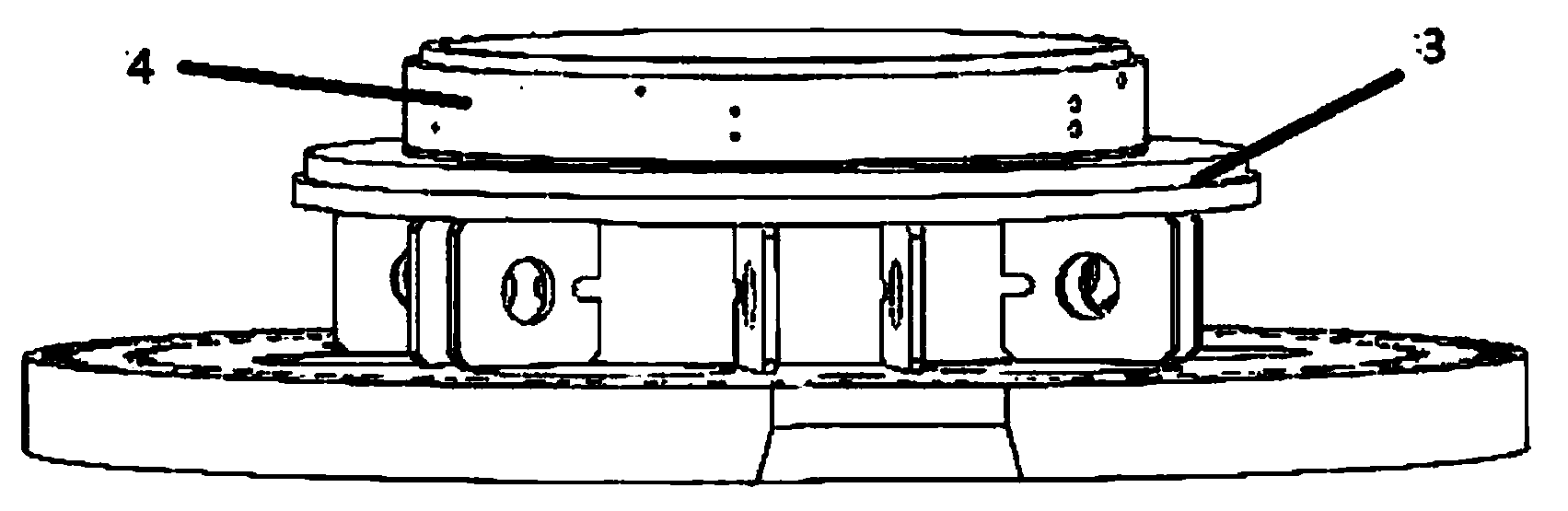

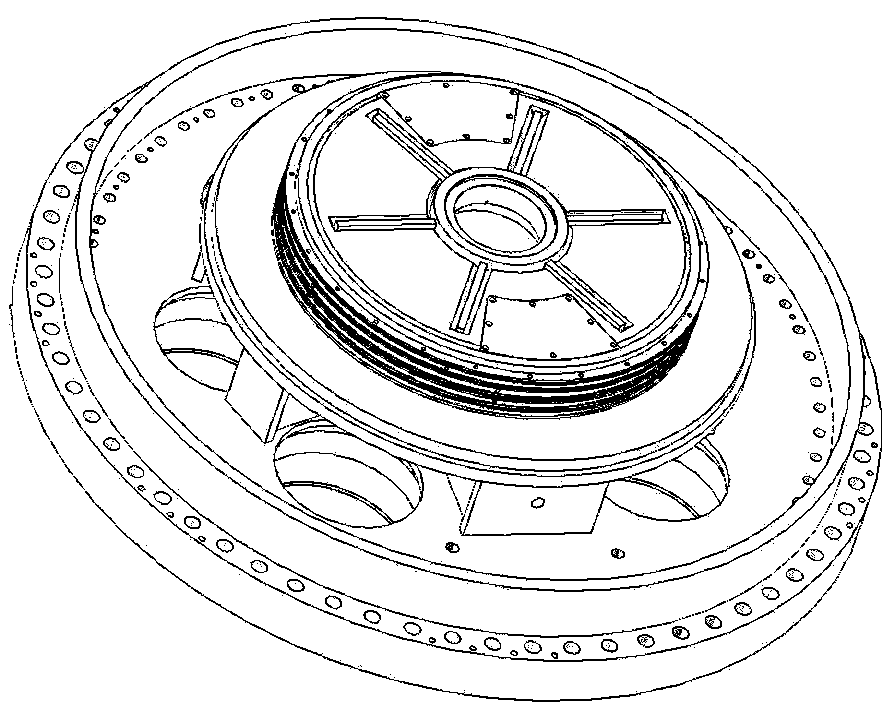

[0069] A drive box for a shield machine, consisting of a large flange 1, a first rib 14, a second rib 16, a third rib 18, a small flange A3, a ring A4, a front cover 9, a ring B10, and a cover frame 6. Small flange B13, small flange C20, cover plate 5, ring C2, ring D12, and fourth rib plate 7.

[0070] Among them, on the side of the large flange 1, the first rib 14, the second rib 16, and the third rib 18 welded around the ring D12 are fixed on the big flange, and above the ribs are the small flange A3 and the ring A4 For the concentric tailor-welded workpiece, six fourth ribs 7 are installed above the small flange A3, and the workpiece formed by welding the front co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circularity | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com