Biological safety negative pressure isolator for poultry

A biosafety and isolator technology, applied in manipulators, manufacturing tools, etc., can solve the problems of not having high-efficiency exhaust filters, endangering the personal safety of experimental staff, and low safety, and achieving the elimination of major public health incidents, major The practical significance of production and the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

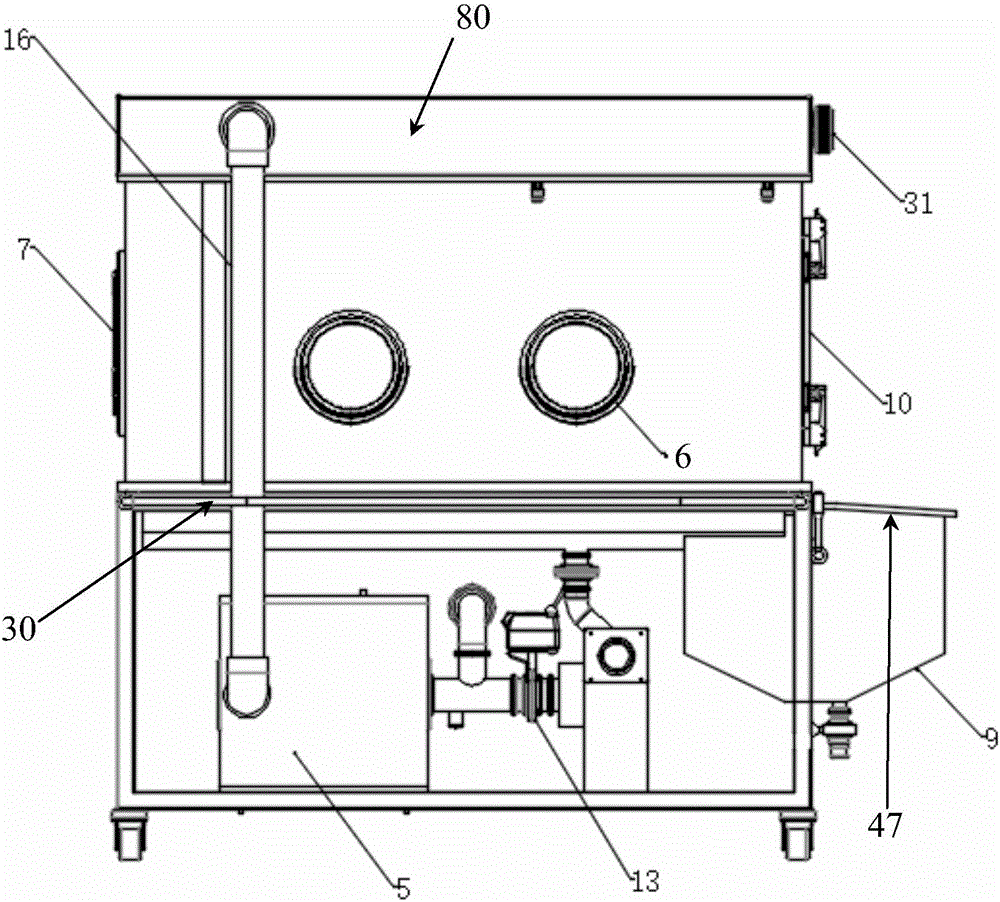

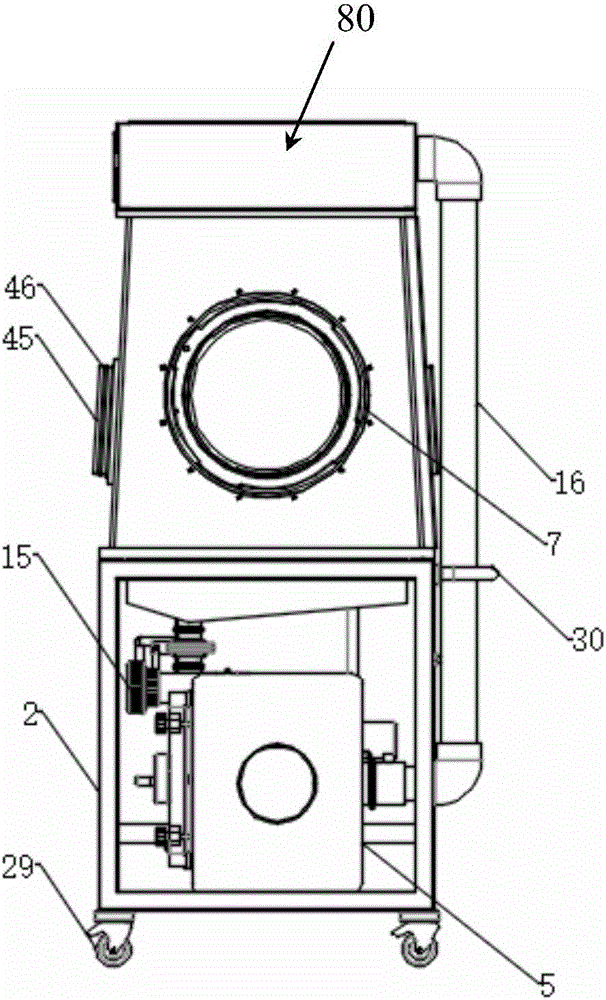

[0069] see Figure 1 to Figure 13 , the present invention provides a biosafety poultry negative pressure isolator, comprising a hollow, airtight operating box 1, the upper and lower sides of the operating box 1 are respectively provided with a hollow equipment layer 80 and a bracket 2.

[0070] In the present invention, the operation box 1 is preferably a box made of hard transparent material, but not limited to this material.

[0071] In the present invention, in terms of specific implementation, the operation box 1 and the equipment layer 80 are airtightly connected.

[0072] In the present invention, in terms of specific implementation, the bottom of the operation box 1 is fixedly connected to the top of the bracket 2 through a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com