Electric precipitation method for high-temperature, high-oil and high-dust gas

A technology of electric dust removal and electric dust removal equipment, which is applied in chemical instruments and methods, electrode cleaning, solid separation, etc., can solve the problems affecting the ability of the dust collection plate to absorb dust, and the dust is not easy to remove the dust of the dust collection plate, so as to achieve the goal of removing dust High oil dust removal efficiency, easy subsequent separation, and large dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

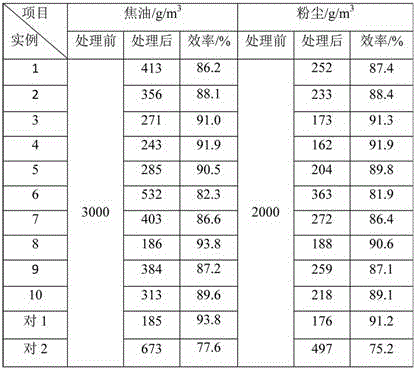

Embodiment 1

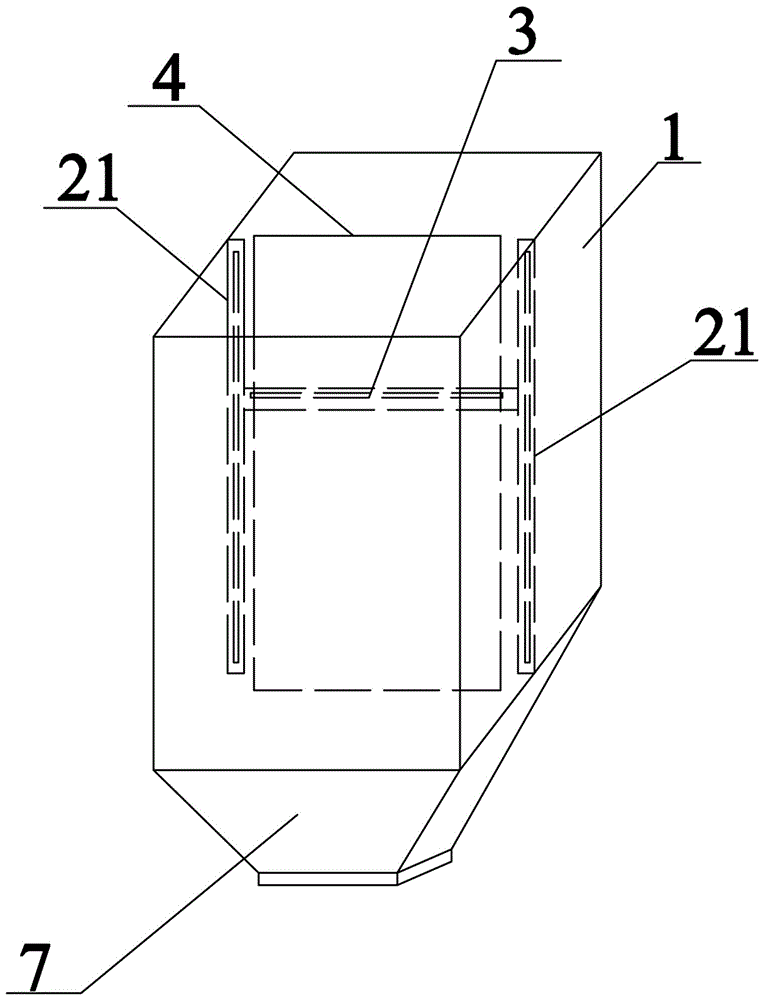

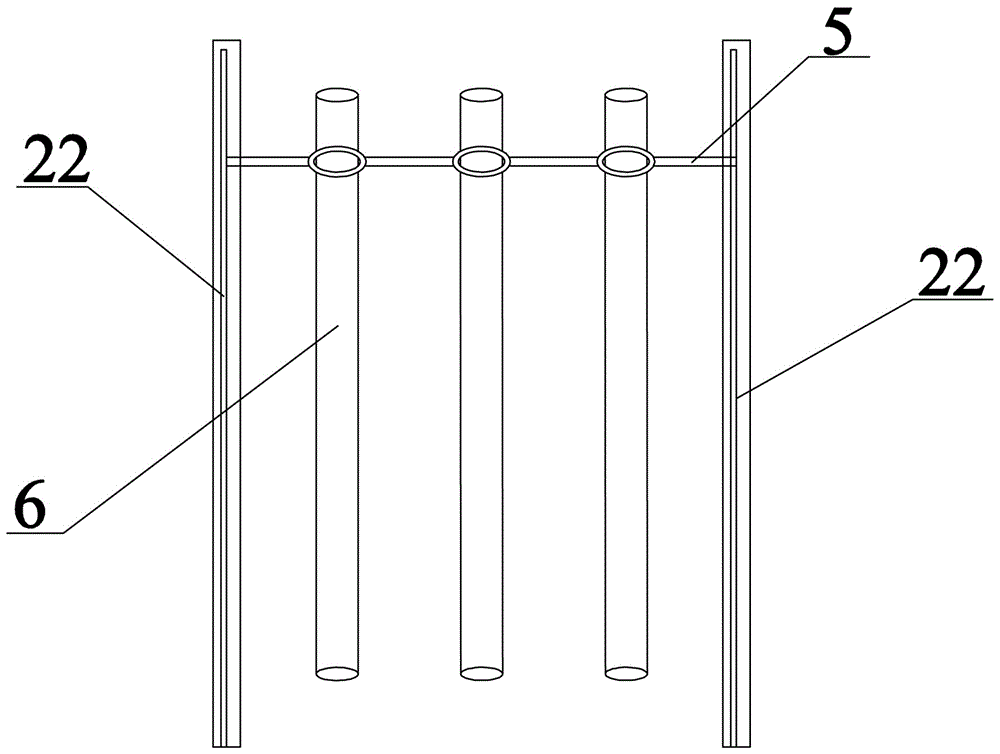

[0032] see figure 1 with figure 2 , a method for electrostatic precipitating of high-temperature, high-oil and high-dust gas, comprising the following steps:

[0033] (1) Firstly connect three electric precipitators in parallel, set the temperature at 500°C and the flow rate at 5m 3 / min, containing tar 3000g / m 3, containing dust 2000g / m 3 The high-temperature, high-oil and high-dust gas is passed into one of the electric dust removal equipment, and the dust removal system is started. After the dust is charged, it is adsorbed by the dust collecting plate 4, and tar is precipitated from the mixed gas and adsorbed on the dust collecting plate 4. The high temperature cleans the mixed gas Discharged from the electrostatic precipitator;

[0034] (2) With the progress of dust removal, the internal temperature of the electrostatic precipitator reaches 390°C, the temperature of the internal components is 180°C, and the putty cake on the dust collection plate 4 becomes thicker and...

Embodiment 2

[0038] see figure 1 with figure 2 , a method for electrostatic precipitating of high-temperature, high-oil and high-dust gas, comprising the following steps:

[0039] (1) First connect four electric precipitators in parallel, set the temperature to 700°C and flow rate to 25m 3 / min, containing tar 3000g / m 3 , containing dust 2000g / m 3 The high-temperature, high-oil and high-dust gas is passed into two of the electrostatic precipitators, and the dust removal system is started. After the dust is charged, it is absorbed by the dust collecting plate 4, and tar is precipitated from the mixed gas and adsorbed on the dust collecting plate 4. The high-temperature clean mixed gas Discharged from the electrostatic precipitator;

[0040] (2) With the progress of dust removal, the internal temperature of the electrostatic precipitator reaches 680°C, and the temperature of the internal parts is 660°C. The putty cake on the dust collecting plate is getting thicker and thicker. At this ...

Embodiment 3

[0044] see figure 1 with figure 2 , a method for electrostatic precipitating of high-temperature, high-oil and high-dust gas, comprising the following steps:

[0045] (1) Firstly connect three electric precipitators in parallel, set the temperature to 750°C and flow rate to 15m 3 / min, containing tar 3000g / m 3 , containing dust 2000g / m 3 The high-temperature, high-oil and high-dust gas is passed into one of the electric dust removal equipment, and the dust removal system is started. After the dust is charged, it is adsorbed by the dust collecting plate 4, and tar is precipitated from the mixed gas and adsorbed on the dust collecting plate 4. The high temperature cleans the mixed gas Discharged from the electrostatic precipitator;

[0046] (2) With the progress of dust removal, the internal temperature of the electrostatic precipitator reaches 680°C, the temperature of the internal parts reaches 680°C, and the putty cake on the dust collecting plate becomes thicker and thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com