Totally-enclosed case heat radiation device

A heat dissipation device and fully enclosed technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems that the protection level of the chassis cannot be achieved, and the sealing of the chassis cannot be achieved, so as to achieve good cooling effect, strengthen the sealing, and prevent dust from entering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

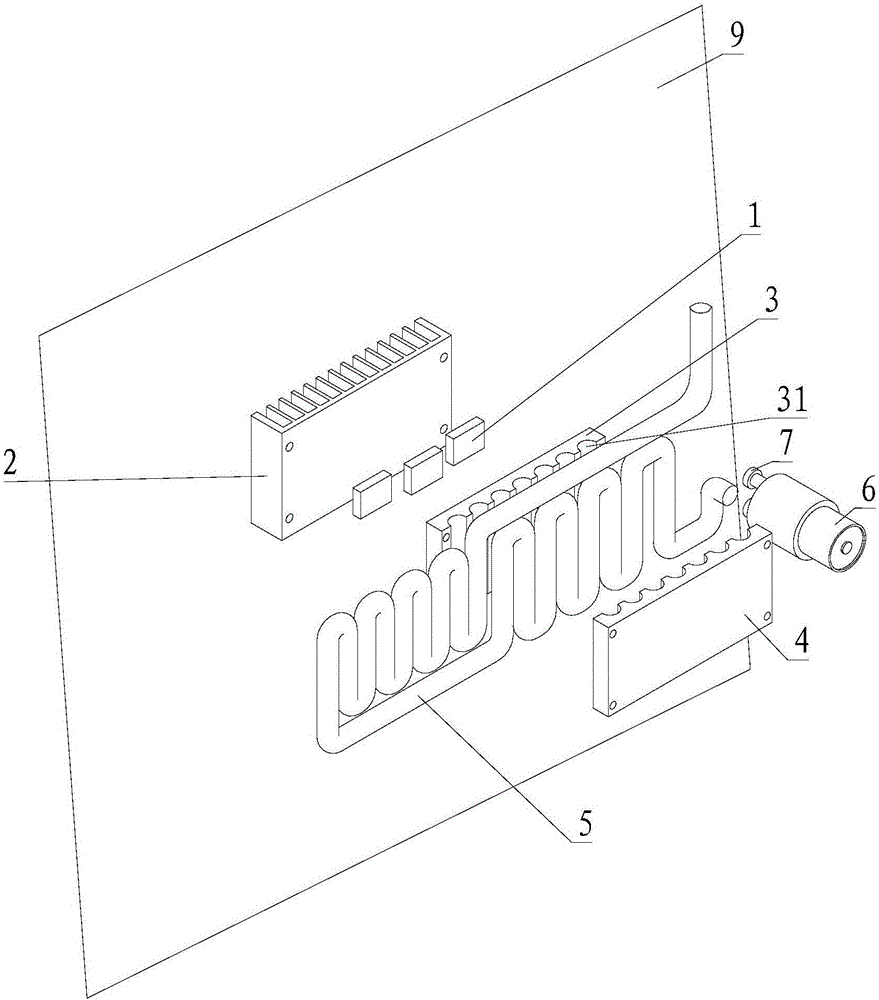

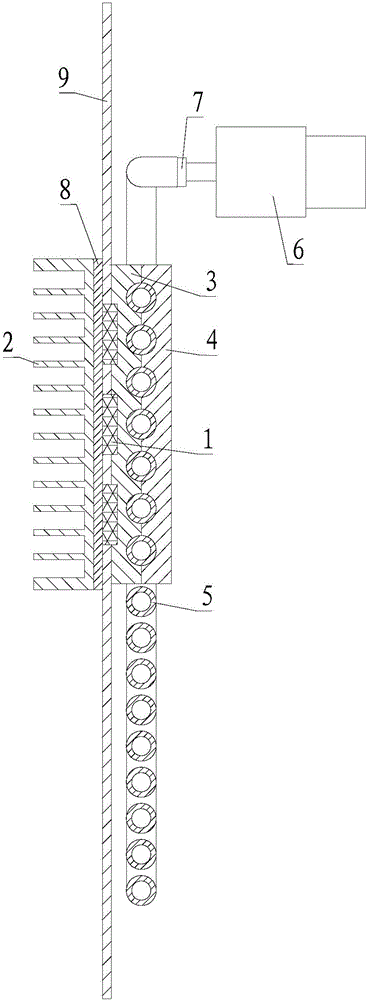

[0034] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is:

[0035] A heat dissipation device for a fully enclosed cabinet, comprising a semiconductor cooling fin 1, a heat sink 2, a first coil splint 3, a second coil splint 4, a coil 5, and a miniature vacuum, the heat dissipation surface of the semiconductor cooling fin 1 is fixed On the side plate 9 of the fully enclosed cabinet of the peripheral, the heat dissipation surface of the semiconductor cooling fin 1 is connected with the heat sink 2, and the heat sink 2 is fixed on the outer surface of the side plate 9 of the cabinet; The first coil splint 3 is arranged opposite to the second coil splint 4, and the opposite surfaces of the first coil splint 3 and the second coil splint 4 are paired with a shape suitable for the coil 5. groove 31, the first coil splint 3 and the second coil splint 4 clamp the coil 5, and the first coil splint 3 is fixed on the side plate 9 of the chassis On the inne...

Embodiment 2

[0036] Please refer to Figure 1 to Figure 2 , the second embodiment of the present invention is:

[0037] A heat dissipation device for a fully enclosed chassis, on the basis of Embodiment 1, further includes a connecting sleeve 7 and a heat-conducting silica gel 8, one end of the connecting sleeve 7 is connected to the air outlet of the miniature vacuum pump 6, and the other end is connected to the air outlet of the micro vacuum pump 6. The air inlet of the coil 5 is connected; the opposite surfaces of the first coil splint 3 and the second coil splint 4 are provided with grooves 31 adapted to the radius shape of the coil 5, so A part of the coil 5 is fixed between the first coil splint 3 and the second coil splint 4, and the other part is located outside the first coil splint 3. The coil 5 is a copper pipe, so The first coil splint 3 and the second coil splint 4 are copper plates, and the air outlet of the coil 5 faces upwards; the heat-conducting silica gel 8 is fixed bet...

Embodiment 3

[0038] Please refer to Figure 1 to Figure 2 , Embodiment three of the present invention is:

[0039]A heat dissipation device for a fully enclosed chassis, on the basis of Embodiment 2, further includes a temperature sensor, the temperature sensor is located in the middle of the peripheral chassis, and the air outlet of the coil 5 faces the power amplifier in the peripheral chassis heat sink. A controller is arranged in the casing of the peripherals, and the temperature sensor, the semiconductor cooling chip 1 and the miniature vacuum pump 6 are all connected with the controller in the casing of the peripherals. When the heat sink works, the temperature threshold is preset, and the actual temperature inside the chassis is detected by a temperature sensor. If the actual temperature is lower than or equal to the temperature threshold, the semiconductor refrigeration chip 1 and the miniature vacuum pump 6 are not turned on; if the actual temperature is higher than the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com